Oxy Acetylene Settings Chart

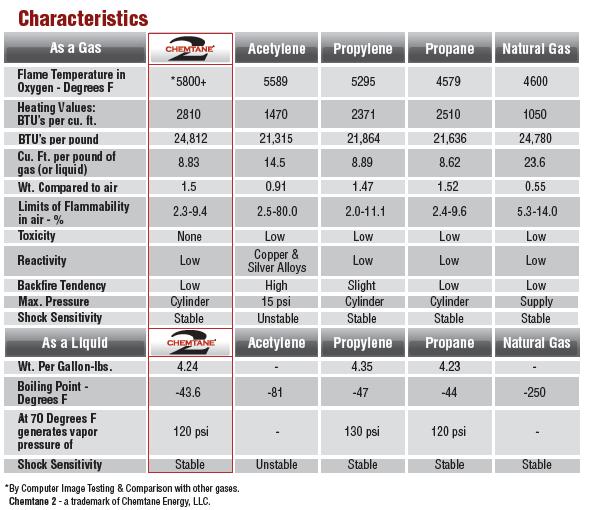

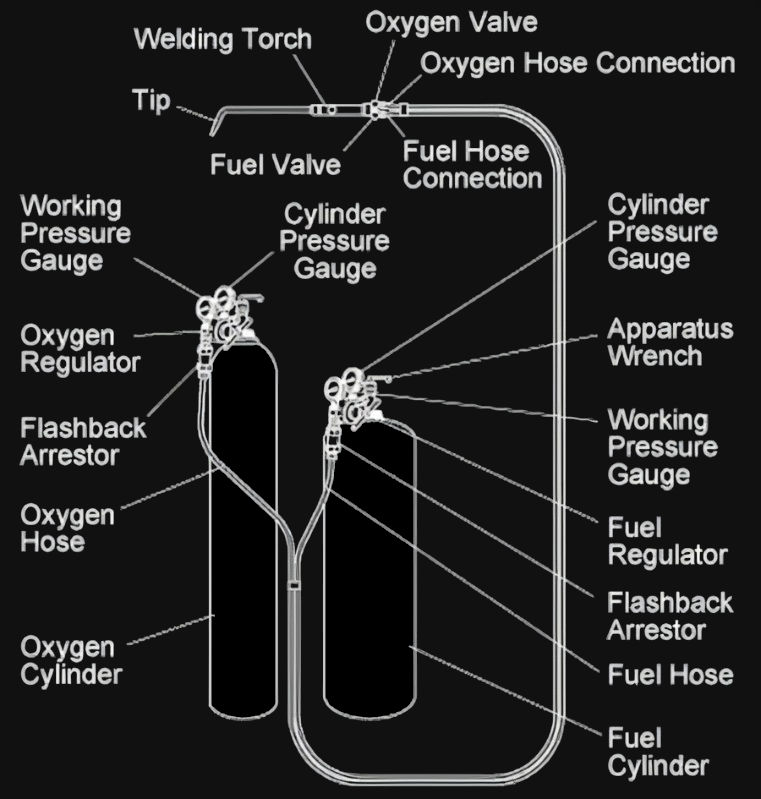

Oxy Acetylene Settings Chart - Setting the correct working pressures. Of cylinders* cutting oxygen preheat oxygen fuel preheat cutting jet preheat in. Setting up the torch and equipment. This is determined by the brand. It is also used in a variety of other applications, such as brazing, soldering, and heating metals. The hole size will vary in size depending on the task. In this article, we will provide you with a comprehensive guide on oxy acetylene cutting torch settings in the year 2023. ** to provide required flow, use 3/8 i.d. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. Adjust to the correct flame setting. Adjust to the correct flame setting. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. For additonal information refer to www.harrisproductsgroup.com. Web harris cutting tip charts. In this article, we will provide you with a comprehensive guide on oxy acetylene cutting torch settings in the year 2023. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. Setting up the torch and equipment. Hose for size 4 and larger. Well suited for work requiring heavy preheat such as rusty or painted plates. You must know the manufacturer or model of your torch and/or the part number of the cutting tips. Medium preheat tip with two milled flat sides. Hose for size 4 and larger. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. This is determined by the brand. Web whether you are a professional welder or a diy enthusiast, understanding the correct settings is essential for optimal performance and safety. The tip is angled at 20o. ** to provide required flow, use 3/8 i.d. The former is used almost exclusively and is ideally suited for welding butt, fillet and lap joints in sheet thicknesses up to approximately 5mm. Adjust to the correct flame setting. Web quick & dirty: Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. Web whether you are a professional welder or a diy enthusiast, understanding the correct settings is essential for optimal performance and safety. Selecting the correct welding attachment/ nozzles. In addition to these easy to follow instructions, you must always be sure to. Setting the correct working pressures. A larger tip will generate more heat, while a. Setting up the torch and equipment. In this article, we will provide you with a comprehensive guide on oxy acetylene cutting torch settings in the year 2023. Adjust to the correct flame setting. Pure oxygen was used instead of ordinary air to increase the flame temperature. Selecting the correct welding attachment/ nozzles. Adjust to the correct flame setting. 3.6k views 1 year ago. In addition to these easy to follow instructions, you must always be sure to follow the torch manufacturer's operating procedures. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. It is also used in a variety of other applications, such as brazing, soldering, and heating metals. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. This will depend on the thickness of the. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. Web whether you are a professional welder or a diy enthusiast, understanding the correct settings is essential for optimal performance and safety. Here's how the process works and how to take the proper safety precautions before you begin. The hole size will vary in size. Well suited for work requiring heavy preheat such as rusty or painted plates. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Make use of correct welding & cutting technique. Hose for size 4 and larger. You must know the manufacturer or. By carefully adjusting the gas pressures, flame characteristics, and cutting speed, operators can optimize their. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Web get ready to learn everything about this powerful welding process. In this article, we will provide you with a comprehensive guide on oxy acetylene cutting torch settings in the year 2023. The tip is angled at 20o. This will be done starting with the cylinders and ending with the torch tip. Here's how the process works and how to take the proper safety precautions before you begin. The former is used almost exclusively and is ideally suited for welding butt, fillet and lap joints in sheet thicknesses up to approximately 5mm. Well suited for work requiring heavy preheat such as rusty or painted plates. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. Web harris cutting tip charts. Retro systems 430 clay valley center, ks 67147. Web understanding the proper oxy acetylene cutting settings is crucial for achieving precise and efficient cutting results. In addition to these easy to follow instructions, you must always be sure to follow the torch manufacturer's operating procedures. A larger tip will generate more heat, while a. ** to provide required flow, use 3/8 i.d.

oxygen and acetylene pressure settings

Oxy Acetylene Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxy Acetylene Torch Tip Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

3.6K Views 1 Year Ago.

If This Important Step Is Skipped, Damage To The Equipment Or Dangerous Flammable Gas Leakage Can Result.

For Additonal Information Refer To Www.harrisproductsgroup.com.

Selecting The Correct Welding Attachment/ Nozzles.

Related Post: