Pipe Fitting Allowance Chart

Pipe Fitting Allowance Chart - The tubing or pipe is heated to a temperature at which the metal is workable and is forced over a mandrel into its final shape. Finding out the face allowance. The different pipe rolling offset formulas; While this implies a greater degree of precision than is ordinarily attained, these dimensions Meets all requirements of astm f 628. Web pvc pipe or fittings. Convert od measurements to nominal size with the following table. How to calculate rolling offsets. Pressure loss in fittings and valves expressed as equivalent length of tube, feet. Also called class 2000, 3000, 6000, 9000 fittings. In addition, ward fittings have a chamfered opening to allow faster and easier pipe engagement. · ul & fm certi ed. Convert od measurements to nominal size with the following table. This webpage will explain the difference between the various series, how each parameter is defined, and show how to find the correct basic dimensions and tolerances for each thread.. Astm a 733 standard spec for welded steel nipple Web the threads have an accurate form, thread length and straightness to allow them to easily engage threaded pipe. The basic dimensions of the american national standard taper pipe thread are given in inches to four or five decimal places. For convenience we have added l1 + l3 which is the. Web all fittings shall be threaded with american national standard pipe threads (ansi/asme b1.20.1) and shall have taper threads, except wrought couplings and wrought caps in sizes 1/8, 1/4, 3/8 and 1/2, which may have Web this comprehensive guide answers questions you have about pipe fittings sizes and pvc fittings sizes! The basic dimensions of the american national standard taper. · 100% pressure tested before leaving the factory. Web this rolling offset calculator, or pipe offset calculator, will help you find the travel distance needed to complete a necessary pipe offset for any typical pipe fitting bends or any bend angle you prefer. This feature also protects the fitting threads from damage during handling. This webpage will explain the difference. Web pipe and flange data weld fitting and steel flange data table of contents gruvlok tech. The tubing or pipe is heated to a temperature at which the metal is workable and is forced over a mandrel into its final shape. The different pipe rolling offset formulas; • only use abs / cpvc / pvc pipe or fittings for water. · ul & fm certi ed. The different pipe rolling offset formulas; In this calculator, you will learn: Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Ansi / asme b1.20.1 dimensions: While this implies a greater degree of precision than is ordinarily attained, these dimensions The basic dimensions of the american national standard taper pipe thread are given in inches to four or five decimal places. • refer to warnings on ppfa’s website and astm d 1785. Astm a 733 standard spec for welded steel nipple Web the jargon, calculations, and. The basic dimensions of the american national standard taper pipe thread are given in inches to four or five decimal places. Web this rolling offset calculator, or pipe offset calculator, will help you find the travel distance needed to complete a necessary pipe offset for any typical pipe fitting bends or any bend angle you prefer. • never test abs. Allowances are for streamlined soldered fittings and recessed threaded fittings. The rough fitting is cooled and machined to apply bevels, then cleaned and marked. Web asme b16.11 is the standard for the forged steel fittings, including socket weld and threaded type. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Pictures are included for reference. The thread engagement or (te) is always required to subtract from the face to center distance to find out the fitting allowance. Meets all requirements of astm f 628. Convert od measurements to nominal size with the following table. The tubing or pipe is heated to a temperature at which the metal is workable and is forced over a mandrel. This feature also protects the fitting threads from damage during handling. • never test abs / cpvc / pvc pipe or fittings with compressed air or gas, or air over water boosters. With the “s” suffix is introduced for ss pipe. Convert od measurements to nominal size with the following table. · galvanized are certi ed to nsf 61 & lead free law. Allowances are for streamlined soldered fittings and recessed threaded fittings. How to calculate rolling offsets. Web this video goes through an example of how to calculate the end to end measurement of a pipe given the center to center measurement and using fitting allowance as a guide. In addition, ward fittings have a chamfered opening to allow faster and easier pipe engagement. Web all steel threaded fittings manufactured for and by sigma piping products conform to, comply with, and are manufactured to the following standards: Web the jargon, calculations, and charts that define npt threads are very different compared with standard metric and inch threads. The thread engagement or (te) is always required to subtract from the face to center distance to find out the fitting allowance. Web this rolling offset calculator, or pipe offset calculator, will help you find the travel distance needed to complete a necessary pipe offset for any typical pipe fitting bends or any bend angle you prefer. • refer to warnings on ppfa’s website and astm d 1785. The rough fitting is cooled and machined to apply bevels, then cleaned and marked. · sizes from 1/8 through 4 diameters.

Threaded Fittings and Carbon Steel/ SS NPT Pipe Fitting manufacturer

PVC Pipe Fittings Sizes And Dimensions Guide (Diagrams And

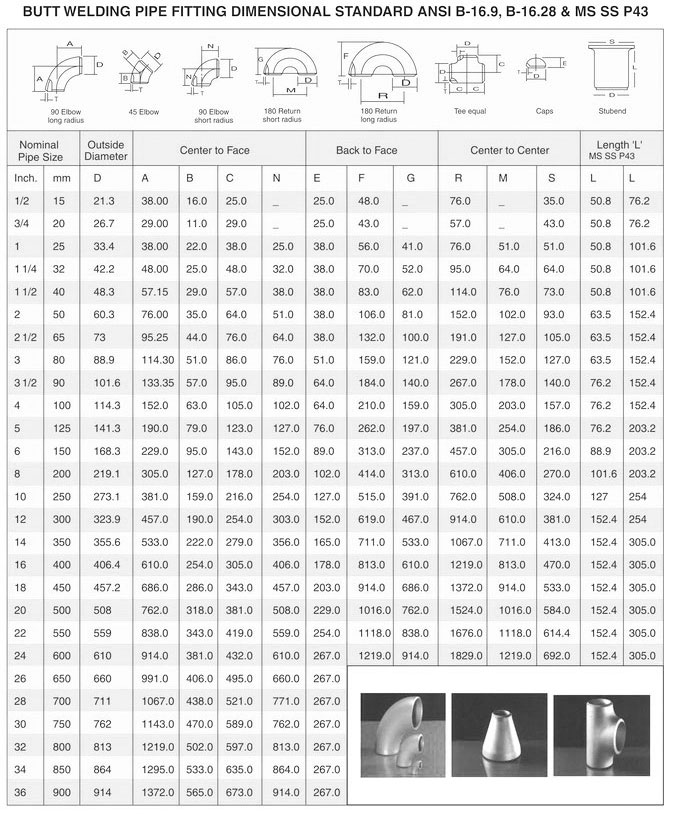

pipe fittings dimension chart pipe schedule chart PDF download

IS 1239 Pipe Fittings, MS IS 1239 Part 2 Elbow, Gi IS 1239 Bend

Pvc Pipe Fitting Allowance Chart at Susan Gilbert Blog

pipe wall thickness schedules chartASME B36.10 B36.19

Pipe fittings socket weld dimention chart Pipe fittings threaded

Metal Ministry Inc. Technical Data

Precise Measurements Made Easy Exploring the Black Pipe Fitting

Pipe Fitting Allowance Chart

The Yield Strength Determined By The 0.2 Percent Ofset Method Is Most Commonly Used.

· Meets Or Exceeds All Applicable Astm & Ansi/Asme Standards.

While This Implies A Greater Degree Of Precision Than Is Ordinarily Attained, These Dimensions

In This Calculator, You Will Learn:

Related Post: