Pipe Span Chart

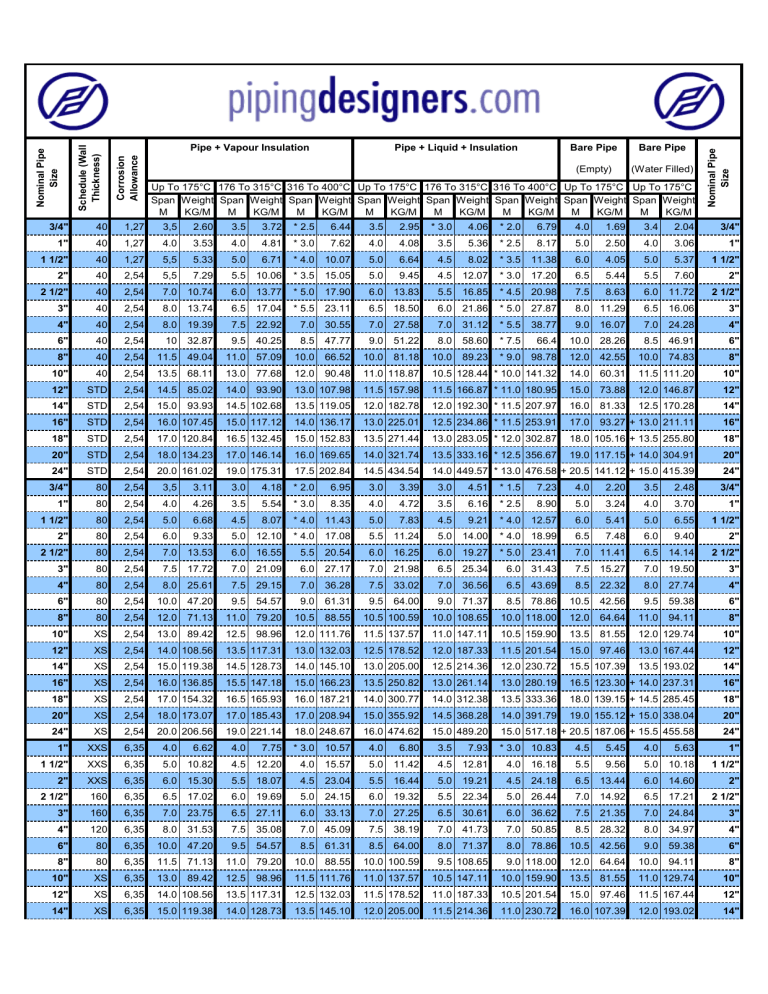

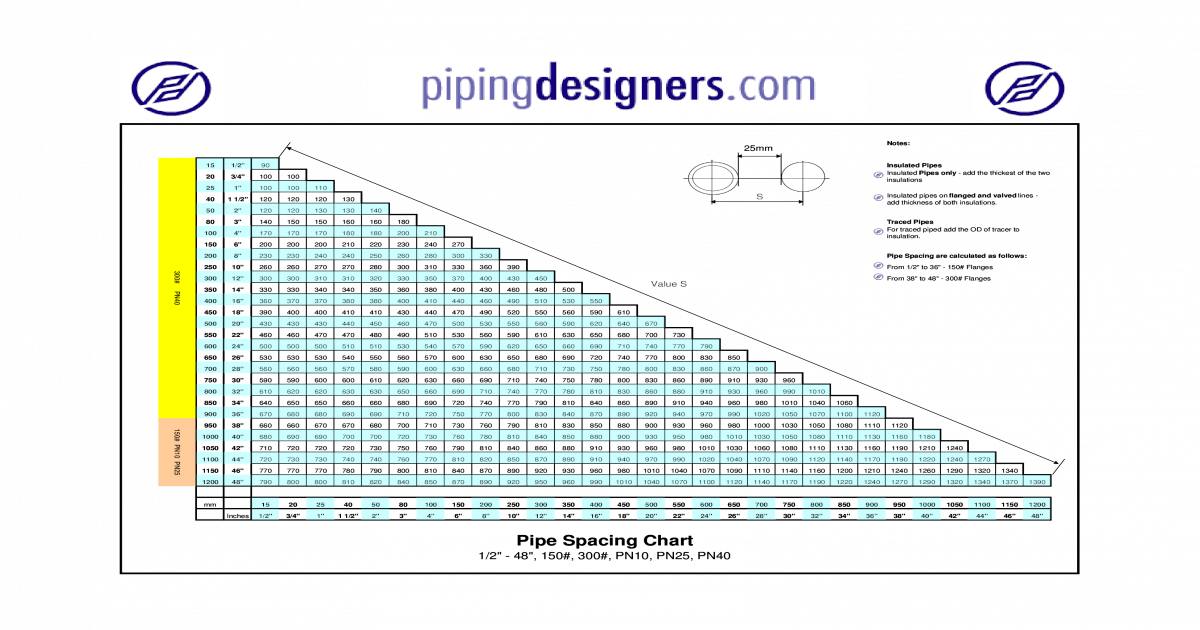

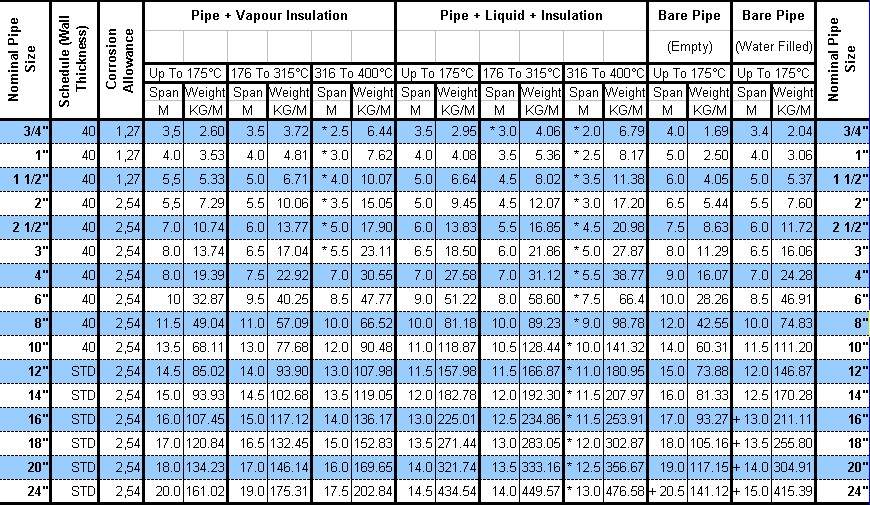

Pipe Span Chart - Distance between steel pipe supports. For the proper working of the piping system, it has to be supported properly. Web use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. These data are typically empirical and are based upon field experience. Pipe allowable support span as per asme b31.3, asme b31.1. Web sample calculation & results. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. The engineering toolbox privacy policy. Piping supports for carrying weights. Web the infrabuild pipe and fittings data charts brochure contains useful technical information and specifications for steel pipe and fittings. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Web some piping system manufacturers and support system manufacturers have information for their products that present recommended spans in tables or charts. Web pipespans is a spreadsheet program written to determine the maximum stress and deflection of a. This chart should only be used as a general guide. Allowable spans are based on a maximum bending stress of 41.37 mpa (6000 psi) or a maximum deflection of 12.7 mm (0.5in). These data are typically empirical and are based upon field experience. The major purpose of pipe supports can be elaborated as follows: Piping supports for carrying weights. Web the infrabuild pipe and fittings data charts brochure contains useful technical information and specifications for steel pipe and fittings. Web the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Pipe outside diameters as per ansi asme b36.10. Post not marked as liked. These data are typically empirical and. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. = 0.3239 m [2] = 20 bar. Distance between steel pipe supports. Web the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. * spans limited by. Stress and deflection are calculated as functions of the pipes' section properties and the weights applied to the pipes. Standardization of wrought steel pipe schedule and. Piping supports for carrying weights. The span is the distance between two points where a pipe is supported, such as at. Allowable spans are based on a maximum bending stress of 41.37 mpa (6000. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. It's an important parameter in piping design and engineering to ensure the structural integrity and safety of a piping system. Allowable spans are based on a maximum bending stress of 41.37 mpa (6000 psi) or a maximum deflection. = 0.3239 m [2] = 20 bar. Spans are based on cpvc pipe filled with water and maximum sag of 2.5mm at center of span. Post not marked as liked. Each piping support detail has its own importance to restrain pipe movements. It's an important parameter in piping design and engineering to ensure the structural integrity and safety of a. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. = 0.3239 m [2] = 20 bar. The values does not apply where loads are concentrated with flanges, valves, specialties, etc. The engineering toolbox privacy policy. Web pipespans is a spreadsheet program written to determine the maximum stress and. Stress and deflection are calculated as functions of the pipes' section properties and the weights applied to the pipes. The values does not apply where loads are concentrated with flanges, valves, specialties, etc. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. The engineering toolbox privacy policy. *. Calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. Support. For the proper working of the piping system, it has to be supported properly. During operation as well as during testing. Pipe supports are required to support the line during all conditions i.e. Pipe outside diameters as per ansi asme b36.10. Standardization of wrought steel pipe schedule and. Each piping support detail has its own importance to restrain pipe movements. Web the steel pipe data chart below can be used to find pipe sizes, diameters, wall thickness, working pressures and more the chart is based on asme/ansi b 36.10 welded and seamless wrought steel pipe and asme/ansi b36.19 stainless steel pipe. Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. Popular internal searches in the engineering toolbox. The span is the distance between two points where a pipe is supported, such as at. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span without excessive deflection or stress. Web some piping system manufacturers and support system manufacturers have information for their products that present recommended spans in tables or charts. Web the steel pipe data chart below can be used to find pipe sizes, diameters, wall thickness, working pressures and more the chart is based on asme/ansi b 36.10 welded and seamless wrought steel pipe and asme/ansi b36.19 stainless steel pipe. Let us calculate the maximum support span for transporting water through a seamless stainless steel pipe (astm a 312 tp 316 l) of 300 nps through a distance of 15 km. Data given in based on the nps tables given by ansi b36.10m and includes pipe wall thickness, outside diameter, nominal diameter. + pipe walls require reinforcing at point of support.

Pipe Support Spacing Chart Pdf

Pipe Span Chart

pipe span chart

Pipe Spacing Chart Piping Designers . Spacing 15mm · Pipe Spacing

Pipe Span Chart Pipe (Fluid Conveyance) Civil Engineering

Pipe Chart A Visual Reference of Charts Chart Master

Pipe Span Chart For Dummies PDF Pipe (Fluid Conveyance) Architecture

Pipe Span Chart PDF Pipe (Fluid Conveyance) Civil Engineering

Pipe Span Chart Pipe (Fluid Conveyance) Civil Engineering

What are piping supports ? Piping engineer world

Allowable Spans Are Based On A Maximum Bending Stress Of 41.37 Mpa (6000 Psi) Or A Maximum Deflection Of 12.7 Mm (0.5In).

Post Not Marked As Liked.

Web Sample Calculation & Results.

Web To Reduce Excessive Loading In Support Itself.

Related Post: