Plasma Cutter Air Pressure Chart

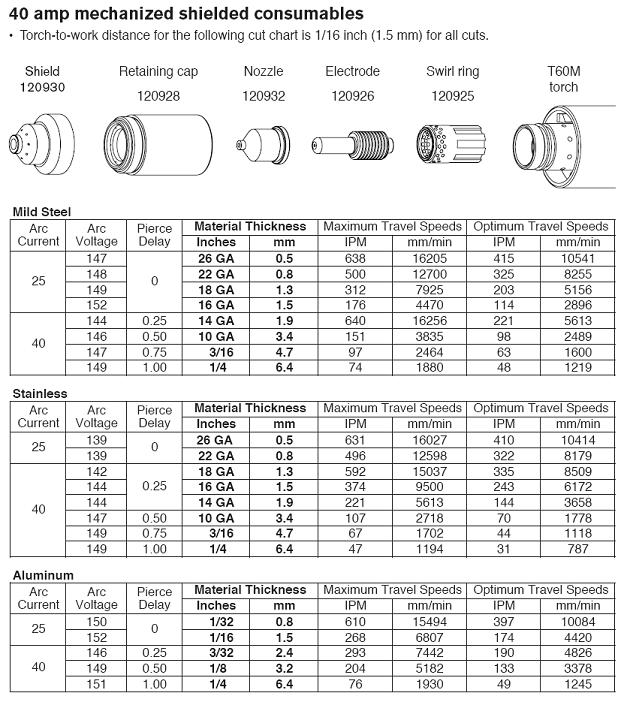

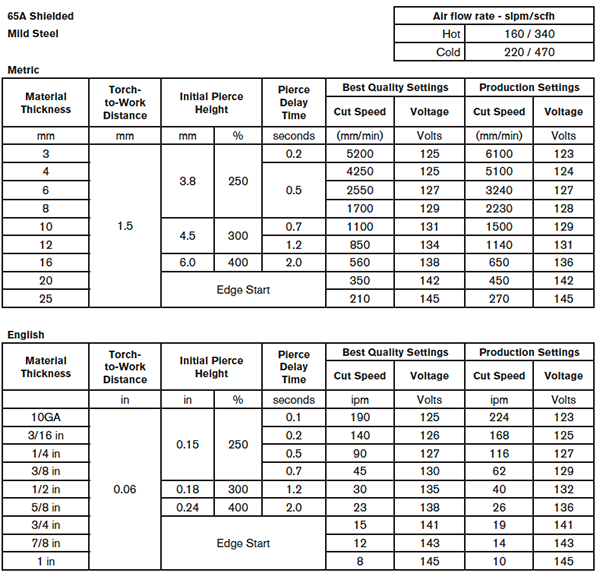

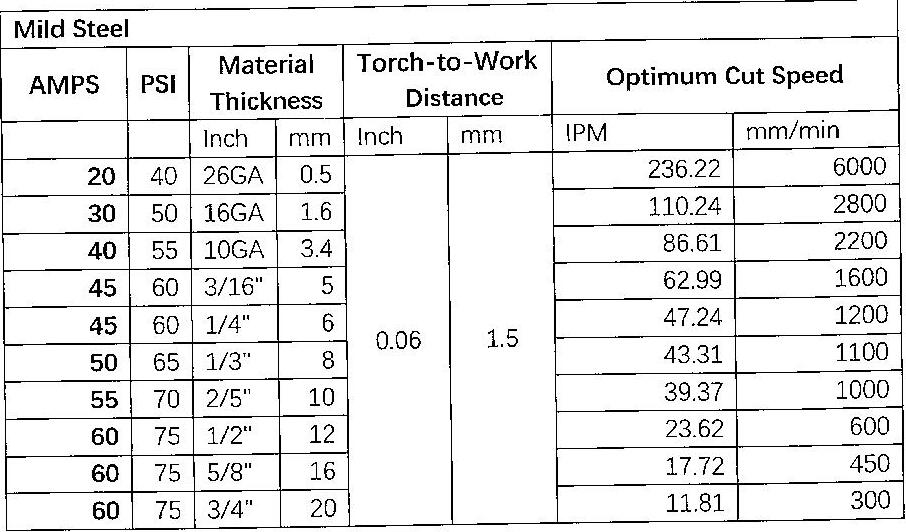

Plasma Cutter Air Pressure Chart - Get more from your system by making sure to have proper air supply. By matching the correct air pressure settings with the correct amperage settings for. Output pressure is adjustable via the pressure regulator. The shop air supply regulator that supply’s air to the cutter is set at 110 psi. Web i have the x45 from plasmadyn machine torch. Plasma cutters need compressed air. Your plasma cutter air pressure table or chart will indicate the precise setting for the air pressure. Web for the majority of the everlast product line, air pressure required to operate the torches is anywhere between 55 to 70 psi. Here is a summary of the recommended parameters for different thicknesses of materials and the corresponding amperage and air pressure settings: Web expectedly, as shown in this video, the higher the air pressure being delivered to the torch, the faster you can cut a metal sheet, and the more powerful heat the torch can produce. The cut charts are divided into two areas: Inlet pressures vary by system. Power supply, whether electricity from your wall or an appropriately sized generator. Unlike welding machines, every australian market plasma cutter you can buy is made to work on compressed air only, including unimig machines. Web i have the x45 from plasmadyn machine torch. The cut charts are divided into two areas: Web expectedly, as shown in this video, the higher the air pressure being delivered to the torch, the faster you can cut a metal sheet, and the more powerful heat the torch can produce. Examples of plasma cutters along with air requirements. Orifice hole size 1mm =.03937. Web cut50 plasma cutter suggested. A plasma cutter like a hypertherm powermax ® system. Web the plasma cutter settings chart is a reference guide that provides recommendations for amperage, gas pressure, cutting speed, and standoff distance based on different material thicknesses and desired cut qualities. Web in this article, we will discuss how plasma cutter air pressure affects its performance, the optimal air pressure for. This is adjusted by the black knob on top of the air pressure regulator and filter on the back of the plasma cutter unit. For a small handheld plasma cutter running at. Web primeweld cut60 cut chart provides the information you need for your best cut. Web a good rule of thumb is the air compressor should be able to. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Web various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Web for example, the recommended setting for a powermax 85 cutting ¼” steel at 85 amps is. Your plasma cutter air pressure table or chart will indicate the precise setting for the air pressure. Web cut charts the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. The following recommended settings are for mechanized cutting at 50 amps. Web what you. The following recommended settings are for mechanized cutting at 50 amps. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Web a good rule of thumb is the air compressor should be able to supply 2.5 liters/second at 90 psi or 625 kpa. Web primeweld cut60. Unlike welding machines, every australian market plasma cutter you can buy is made to work on compressed air only, including unimig machines. Web i have the x45 from plasmadyn machine torch. Orifice hole size 1mm =.03937. Web air compressor system pressure is preset and usually between 100 psi and 135 psi. The following recommended settings are for mechanized cutting at. The following recommended settings are for mechanized cutting at 50 amps. Output pressure is adjustable via the pressure regulator. Web in this article, we will discuss how plasma cutter air pressure affects its performance, the optimal air pressure for different types of plasma cutters and material thicknesses, and how to adjust the air pressure if required. Web primeweld cut60 cut. Web cut charts the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Inlet pressures vary by system. By matching the correct air pressure settings with the correct amperage settings for. Web the following cut charts show the consumable parts, cutting speeds and the. The cut charts are divided into two areas: Web in this article, we will discuss how plasma cutter air pressure affects its performance, the optimal air pressure for different types of plasma cutters and material thicknesses, and how to adjust the air pressure if required. However, different plasma cutters require varied air pressures (compressed air), depending on the central unit air compressor and the material’s thickness. Power supply, whether electricity from your wall or an appropriately sized generator. Web a good rule of thumb is the air compressor should be able to supply 2.5 liters/second at 90 psi or 625 kpa. A plasma cutter like a hypertherm powermax ® system. Web primeweld cut60 cut chart provides the information you need for your best cut. Get more from your system by making sure to have proper air supply. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. This is adjusted by the black knob on top of the air pressure regulator and filter on the back of the plasma cutter unit. The shop air supply regulator that supply’s air to the cutter is set at 110 psi. Web how to set the correct air pressure and amperage for your plasma cutter. Web i have the x45 from plasmadyn machine torch. Web cut charts the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. The following recommended settings are for mechanized cutting at 50 amps. Web what you need to begin.

Hypertherm Powermax 65 Plasma Cutter E and M Motor Factors

LGK 100 Plasma Cutter

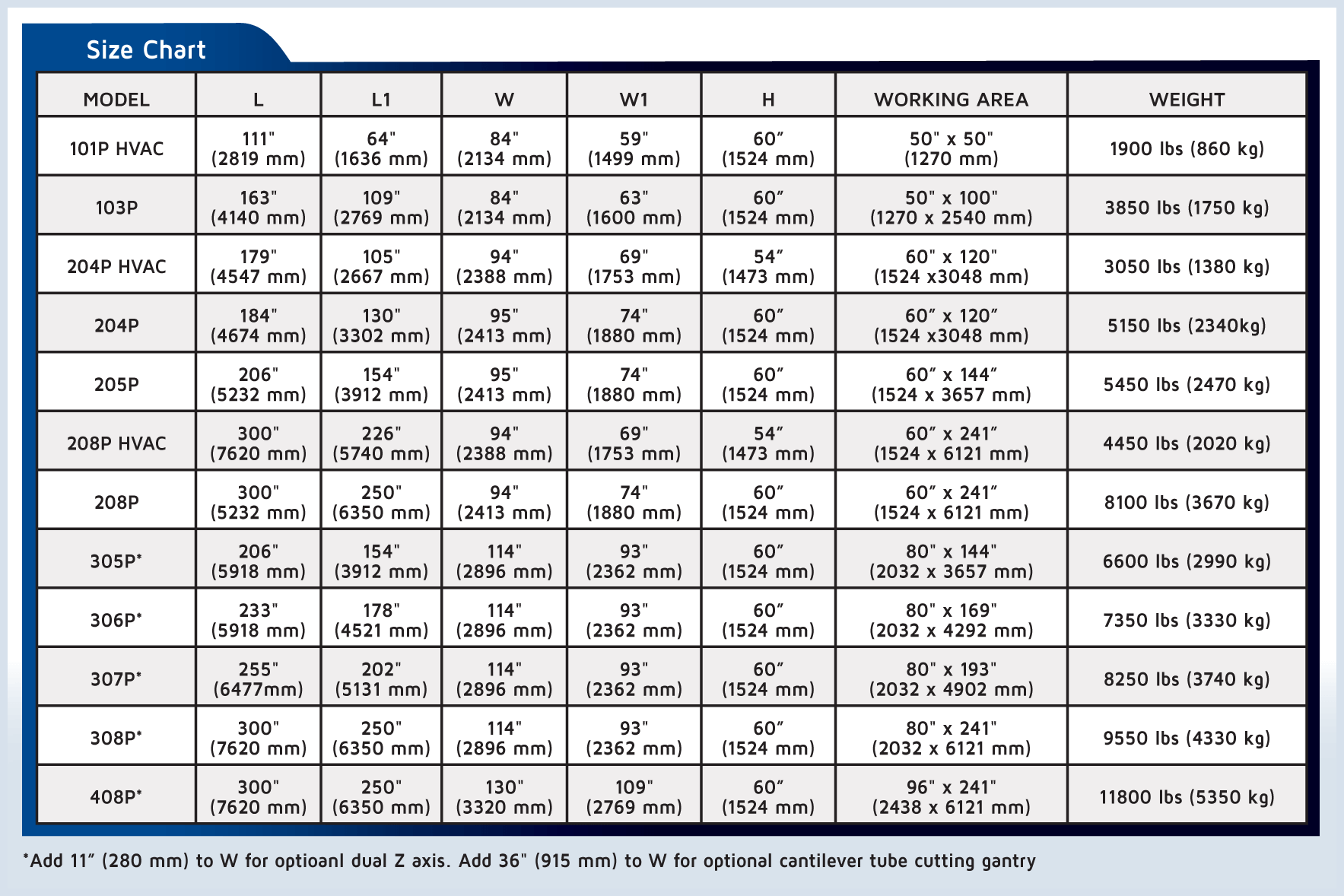

Plasma Cutting Machine 3000 Series MultiCam East, Shrewsbury PA

A check list for a plasma cutting table retrofit The Fabricator

Consejos básicos mejorar la calidad de corte por plasma Hypertherm

CNC Plasma

CNC Plasma Cutting SV Seeker

The Ultimate Guide to Plasma Cutting UNIMIG Welding Guides & Tutorials

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

Plasma Cutter Air Pressure Chart

Typically, All You Need Is:

Here Is A Summary Of The Recommended Parameters For Different Thicknesses Of Materials And The Corresponding Amperage And Air Pressure Settings:

Examples Of Plasma Cutters Along With Air Requirements.

Web For The Majority Of The Everlast Product Line, Air Pressure Required To Operate The Torches Is Anywhere Between 55 To 70 Psi.

Related Post: