Plasma Cutter Amps Thickness Chart

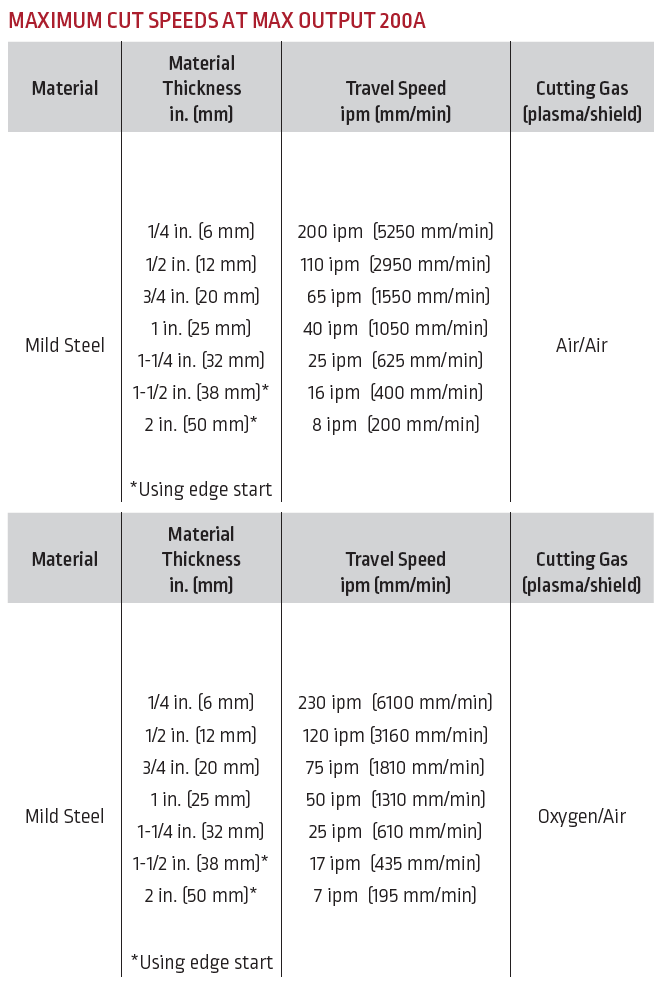

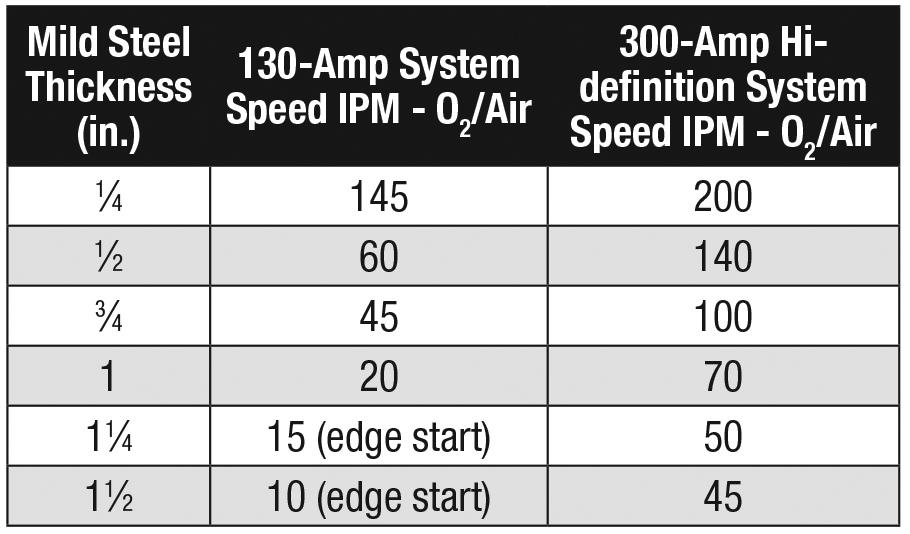

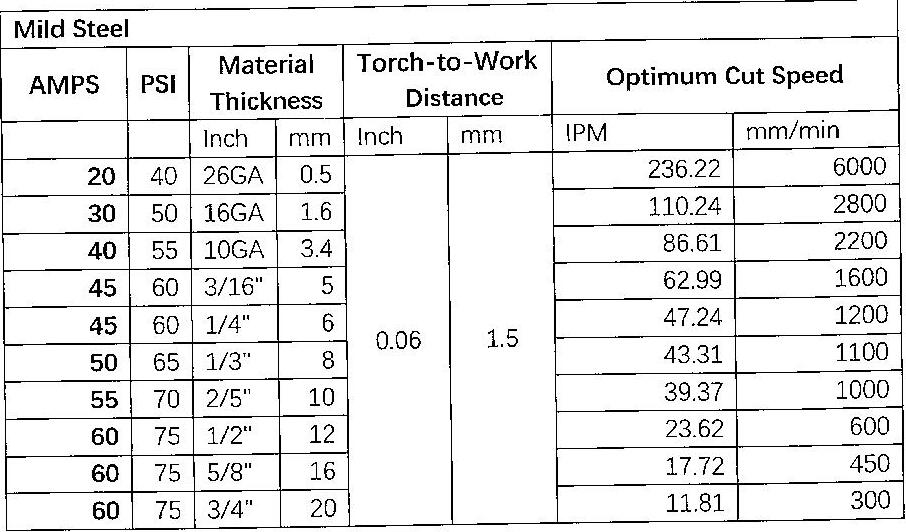

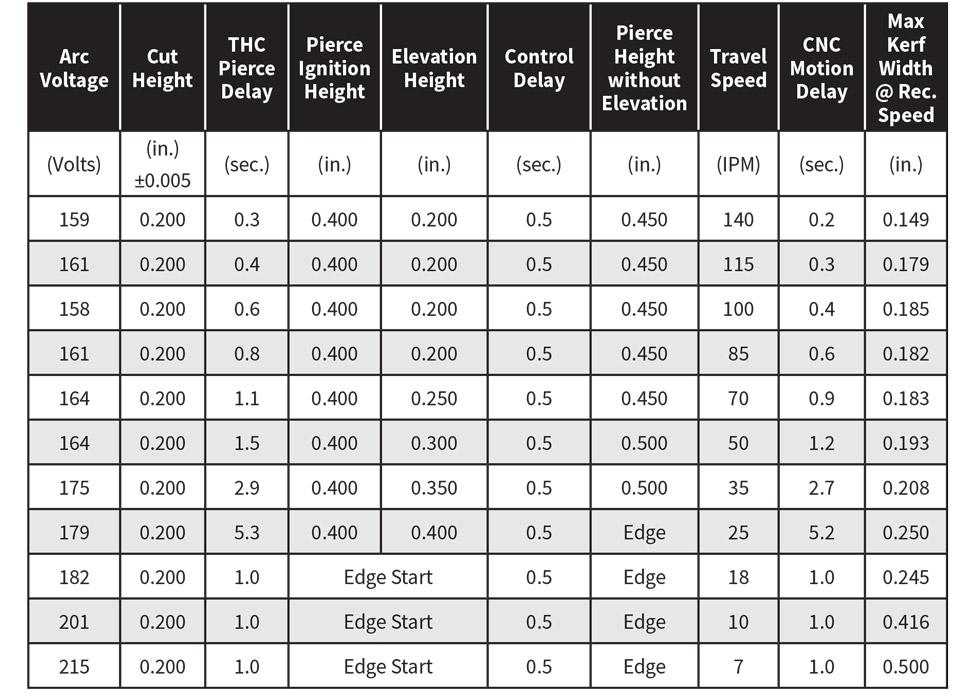

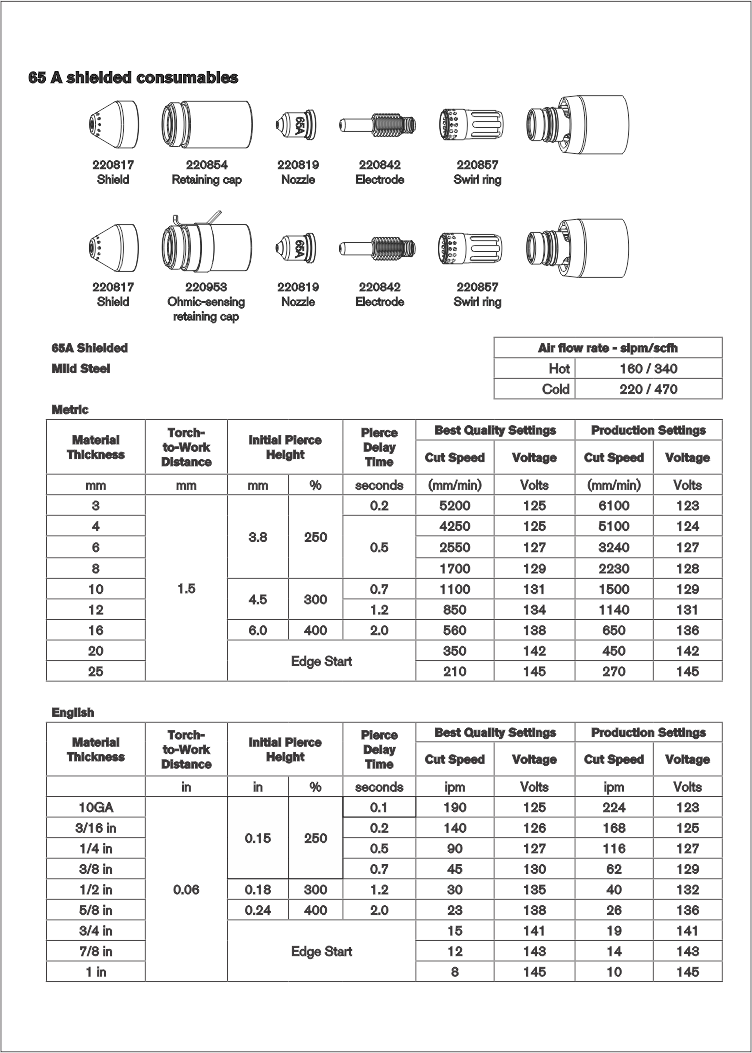

Plasma Cutter Amps Thickness Chart - Orifice hole size 1mm =.03937. Thin metal sheets and their characteristics. The following recommended settings are for mechanized cutting at 50 amps. Web cut charts are intended to provide a good starting point for each different cut assignment. Cut with water table & 1/4 thick slat 4” wide layed across work area to help with any warpage, but didn’t have any even cutting @ that speed. For ½” cut, 50 amps works out well, etc. Web plasma cutting parameter guide. Web the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Refer to the plasma cutter's user manual: Small adjustments may have to be made to achieve the best cut. However, increasing the preflow flowrates too much may affect plasma starting reliability (misfiring). Thin metal sheets and their characteristics. Web once you choose your amperage, select the appropriate chart, find your material thickness in the left column, and look to the columns on the right for the appropriate settings. So you can almost eliminate distortion from excessive heat and skyrocket. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. The thickness of metal you will routinely cut and maximum metal thickness are important in selecting the right plasma cutter. This resulted in near perfect cut. Web to determine the optimal amperage and air setting for your plasma cutter, consider. Web a plasma cutter amps thickness chart is an invaluable tool for anyone working with metal. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Every cutting system requires “fine tuning” for each cutting application in order the desired cut quality. In the charts, we will provide info on. However, increasing the preflow flowrates too much may affect plasma starting reliability (misfiring). For ½” cut, 50 amps works out well, etc. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch settings required for each process. * slightly increasing the test preflow o2 and n2 flowrates may increase piercing capability on the thicker. If you can’t find it or add to it let me know your settings and i’ll add them in. Web plasma cutting parameter guide. The following parameters can be used as a guide to cutting diferent materials and thicknesses with the viper cut 30. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch. In the charts, we will provide info on air pressure, amperage, pierce height, cut height, and feed rate (cutting speed). Web for 3/8” cut, 40 amps works out well for most brands of plasma cutters. The following recommended settings are for mechanized cutting at 50 amps. Feel free to add to it. Web put together and started a primeweld cut. Web the following charts will give you some starting settings to use when programming your plasma jobs. It provides concise, accurate information about the thickness of different metals which can be cut using a particular plasma cutter amp rating. When you get to the cut speed and voltage columns, i suggest using the values in the best quality settings columns. Web plasma cutting parameter guide. Every cutting system requires “fine tuning” for each cutting application in order the desired cut quality. Web a plasma cutter amps thickness chart is an invaluable tool for anyone working with metal. It provides concise, accurate information about the thickness of different metals which can be cut using a particular plasma cutter amp rating. When. However, increasing the preflow flowrates too much may affect plasma starting reliability (misfiring). Web cut charts are intended to provide a good starting point for each different cut assignment. Web put together and started a primeweld cut 60 cut chart for those interested. Plasma cutting considerations for thin metal sheets. Web our cobot cutter can easily cut faster than 100. It provides concise, accurate information about the thickness of different metals which can be cut using a particular plasma cutter amp rating. Web to determine the optimal amperage and air setting for your plasma cutter, consider the following steps: This resulted in near perfect cut. The following parameters can be used as a guide to cutting diferent materials and thicknesses. Orifice hole size 1mm =.03937. Selecting the appropriate plasma cutter for thin metals. Web the following charts will give you some starting settings to use when programming your plasma jobs. If you can’t find it or add to it let me know your settings and i’ll add them in. Web the cutting charts shown on the following pages are intended to give the operator the best starting point to use when making a cut on a particular material type and thickness. Edges really nice and straight. Every cutting system requires “fine tuning” for each cutting application in order the desired cut quality. Web in finecut charts, the amperage setting for each thickness is included in the cut chart. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Small adjustments may have to be made to achieve the best cut. Web for 3/8” cut, 40 amps works out well for most brands of plasma cutters. Web plasma cutting parameter guide. Web the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Web our cobot cutter can easily cut faster than 100 ipm (depending on thickness). Refer to the plasma cutter's user manual:

Plasma Cutting Thickness Chart

Plasma Cutter Amps Thickness Chart Online Shopping

Plasma Cutter Amps Thickness Chart Online Shopping

Plasma Cutter Amps Thickness Chart Online Shopping

Plasma Cutter Amps Thickness Chart PDF Metalworking Tools

Plasma Cutter Amps Thickness Chart (PDF Download)

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

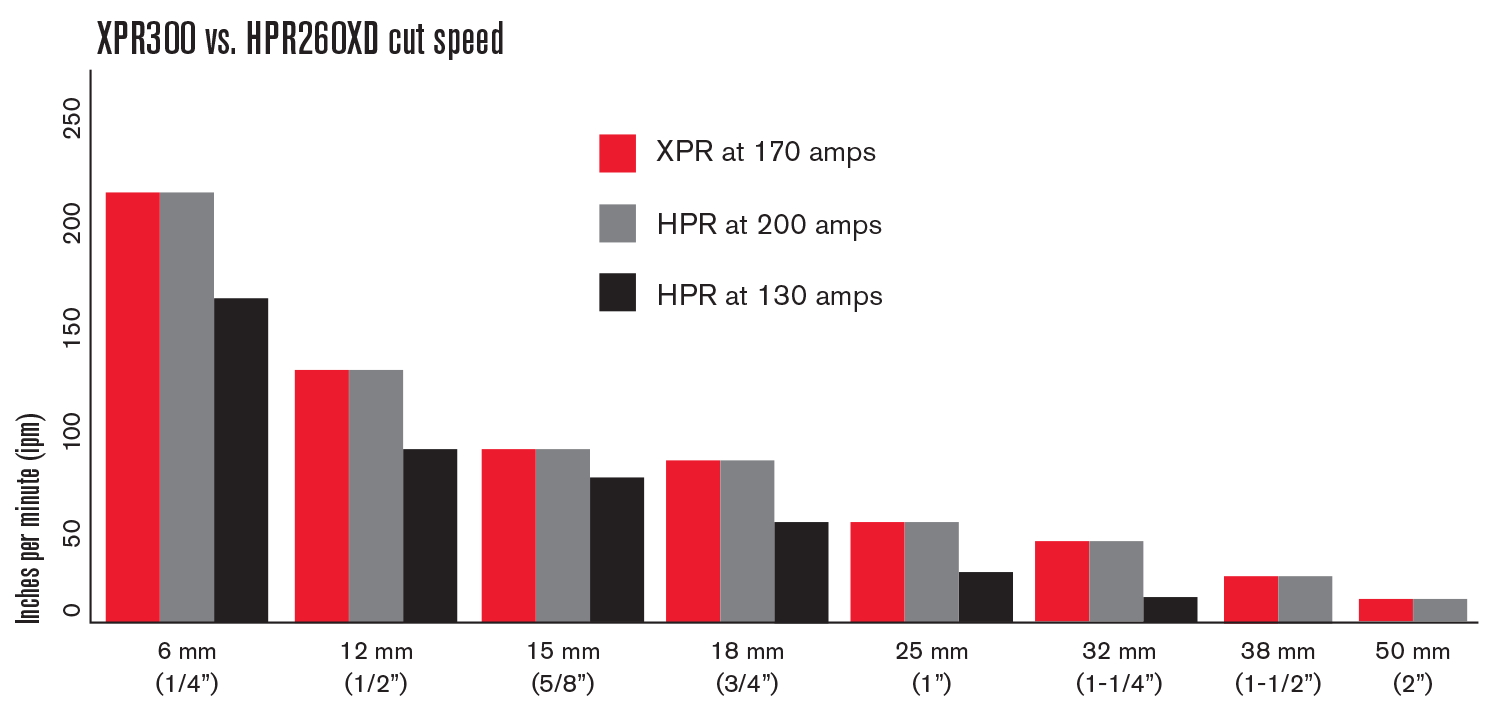

UltraCut HighPrecision plasma cutting systems. 130 amp 800 amp

A check list for a plasma cutting table retrofit The Fabricator

Plasma Cutter Thickness Chart

Keep In Mind This Isn’t The Maximum Thickness Of Cut That A Plasma Cutter Is Capable Of Cutting But Rather, It Is A Good Rule To Follow For Decent Cutting Speed And Quality.

Web A Plasma Cutter Amps Thickness Chart Is An Invaluable Tool For Anyone Working With Metal.

Web The Plasma Cutter Settings Chart Is A Reference Guide That Provides Recommendations For Amperage, Gas Pressure, Cutting Speed, And Standoff Distance Based On Different Material Thicknesses And Desired Cut Qualities.

Share This | Print This.

Related Post: