Plywood Strength Chart

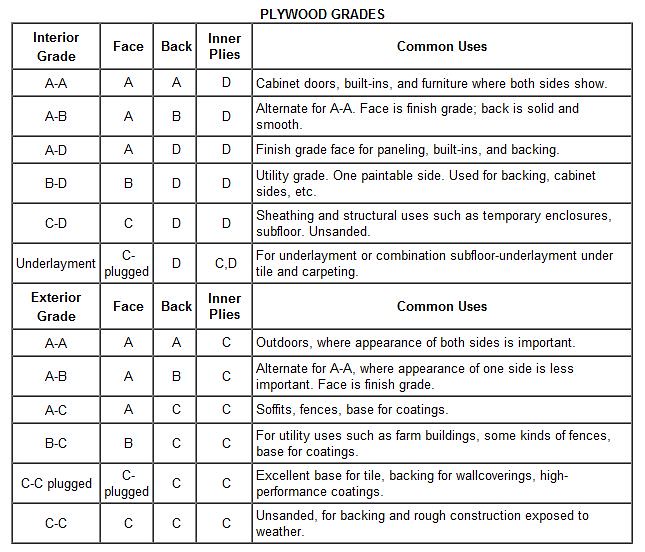

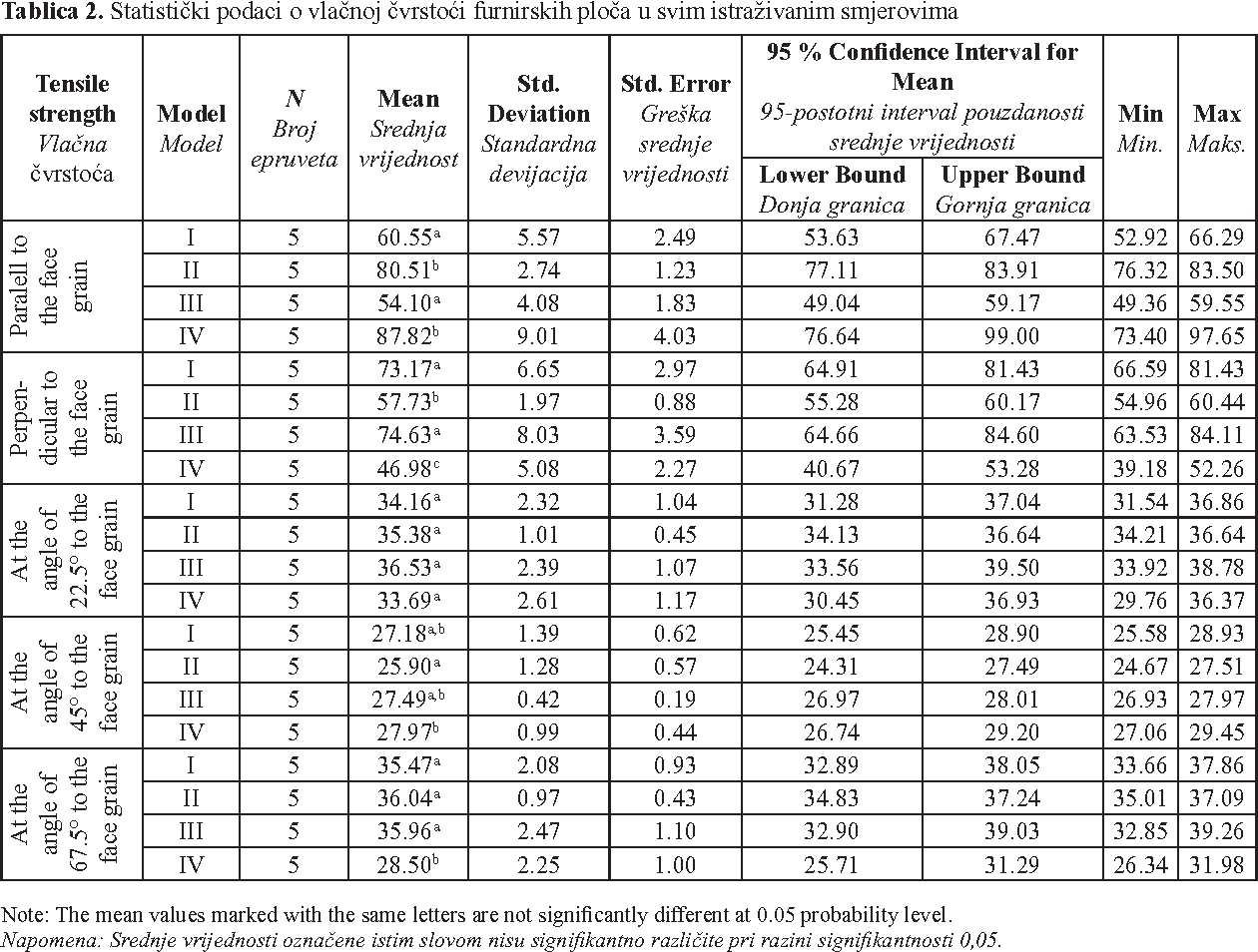

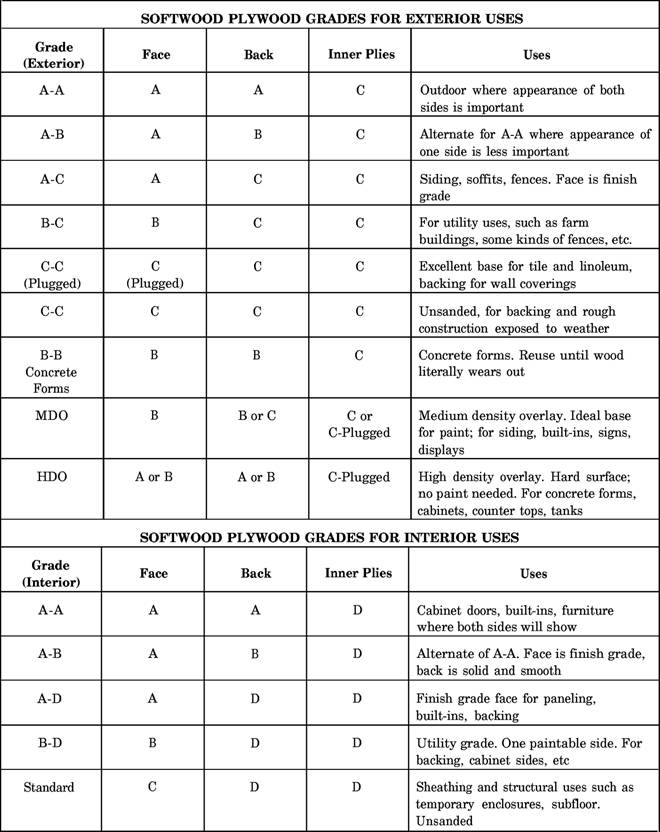

Plywood Strength Chart - Proper use of this calculator aligns with building codes and safety standards, ensuring. However, the most commonly available sizes are 1/4″, 3/8″, 1/2″, 5/8″, and 3/4″. Whether you’re working with imperial or metric plywood, keep reading to find helpful reference tables of the weights of standard plywood sheet sizes and thicknesses. These factors include the thickness and grade of the plywood, the span or distance between supports, and the type of load applied. Plywood is manufactured in numerous thicknesses and is typically identified by its nominal thickness, which can vary by 1/16” or more from panel to panel. The design capacities presented in table a include the grade and construction factor, cg. Web plywood thickness chart. Web 8 billion trees | 8 billion trees official site Web a complete analysis of wood’s mechanical properties is complex, but understanding a few basics of lumber strength will allow you to size joists and rafters with the use of span tables. Panels of the same thickness with more plies are stronger, as are those made of hardwood layers. Plywood is manufactured in numerous thicknesses and is typically identified by its nominal thickness, which can vary by 1/16” or more from panel to panel. Plywood strength depends primarily on its thickness, among other factors. The sizing is grouped into nominal and actual thickness, with nominal thickness describing the plywood board before it. Web here is a chart that details. The increased thickness means plywood supports much more weight, as it can redistribute the stress away from the center. This makes it clear that the thickness of plywood 12 makes all the difference when it comes to weight bearing and strength. Web powered by @calculator ultra. Whether you’re working with imperial or metric plywood, keep reading to find helpful reference. These factors include the thickness and grade of the plywood, the span or distance between supports, and the type of load applied. Web mastering the plywood thickness chart is crucial for getting the ideal measurements for your project. Quick reference guide to specifications and applications. Variables like thickness, length, and how much support is added all work to determine how. Basic plywood strength and stiffness characteristics for a given panel thickness are determined by the wood species group and veneer grade used in. The increased thickness means plywood supports much more weight, as it can redistribute the stress away from the center. Web the plywood specifiers guide | hanson plywood. The sizing is grouped into nominal and actual thickness, with. Calculating the weight of plywood is crucial for a variety of reasons, including shipping, structural calculations, and material handling. Web typically, softwood plywood 1/4” thick can hold 5psf, 1/2″ 35psf, 3/4″ around 80psf, and 1” approximately 164psf. Web here is a chart that details precisely how the thickness and span rating of a sheet of plywood work together in making. The design capacities presented in table a include the grade and construction factor, cg. The apa ( american plywood association) has created design specifications for producing various plywood products. This makes it clear that the thickness of plywood 12 makes all the difference when it comes to weight bearing and strength. Different types of plywood and their standard thickness options.. Plywood, a common building material, is known for its strength, durability, and versatility. Web group 1 woods exhibit the highest strength and stiffness characteristics and group 5 woods the lowest. Web a complete analysis of wood’s mechanical properties is complex, but understanding a few basics of lumber strength will allow you to size joists and rafters with the use of. Web mastering the plywood thickness chart is crucial for getting the ideal measurements for your project. Web the plywood specifiers guide | hanson plywood. Web density, fibre stress, compressive strength and modulus of elasticity of clear wood, panel and structural timber products. The apa ( american plywood association) has created design specifications for producing various plywood products. Plywood, a common. Loads are provided for applications where the panel strength axis is applied across supports and applied parallel to supports. For each combination of span and span rating, loads are given for deflections of l/360, Web standard plywood thickness chart. Web a complete analysis of wood’s mechanical properties is complex, but understanding a few basics of lumber strength will allow you. A comprehensive advisory service for architects, designers and specifiers in the specification and uses of plywood products in all applications. Basic plywood strength and stiffness characteristics for a given panel thickness are determined by the wood species group and veneer grade used in. Web 'hvljq so\zrrg 5dw suhvvxuh uhvlvwdqfh iru orqj whup gxudwlrq ordg 7lpehu jhrphwulf surshuwlhv 7klfnqhvv ri so\zrrg. Web the plywood specifiers guide | hanson plywood. Loads are provided for applications where the panel strength axis is applied across supports and applied parallel to supports. Web the standard affordable plywood supports a total load capacity between five to fifty pounds. Uniform loads for some applications can be read directly from the tables. Plywood strength mostly depends on its thickness, number of layers, wood type, and grain direction. The thickness can also be affected by humidity as wood will swell with moisture content. In it, they state that softwood plywood should weigh approximately 3 pounds per square foot per inch of thickness. The increased thickness means plywood supports much more weight, as it can redistribute the stress away from the center. Let’s start with the most common plywood product, softwood plywood. Web 8 billion trees | 8 billion trees official site This makes it clear that the thickness of plywood 12 makes all the difference when it comes to weight bearing and strength. Panels of the same thickness with more plies are stronger, as are those made of hardwood layers. These factors include the thickness and grade of the plywood, the span or distance between supports, and the type of load applied. Quick reference guide to specifications and applications. Web density, fibre stress, compressive strength and modulus of elasticity of clear wood, panel and structural timber products. Web here is a chart that details precisely how the thickness and span rating of a sheet of plywood work together in making your plywood as strong as possible:

Osb thickness chart

Flexural strength and stiffness of southern pine plywood Semantic Scholar

Shear strength of plywood panels* Download Table

Strength Of Plywood Chart

Osb Plywood Weight Chart

Strength Of Plywood Chart

Flexural strength and stiffness of southern pine plywood Semantic Scholar

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood)

Strength Of Plywood Chart

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood

However, The Most Commonly Available Sizes Are 1/4″, 3/8″, 1/2″, 5/8″, And 3/4″.

Plywood Is Manufactured In Numerous Thicknesses And Is Typically Identified By Its Nominal Thickness, Which Can Vary By 1/16” Or More From Panel To Panel.

Web Group 1 Woods Exhibit The Highest Strength And Stiffness Characteristics And Group 5 Woods The Lowest.

A Comprehensive Advisory Service For Architects, Designers And Specifiers In The Specification And Uses Of Plywood Products In All Applications.

Related Post: