Polyester Resin Mix Ratio Chart

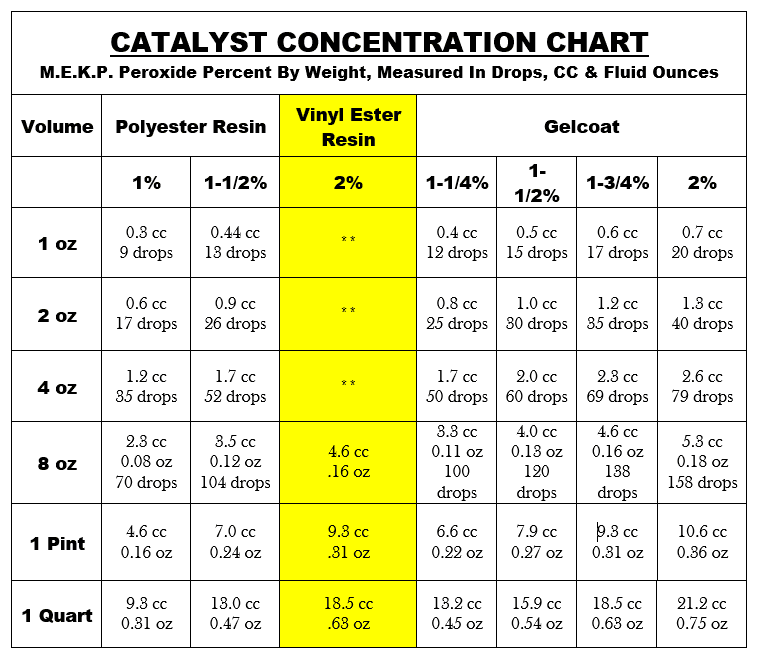

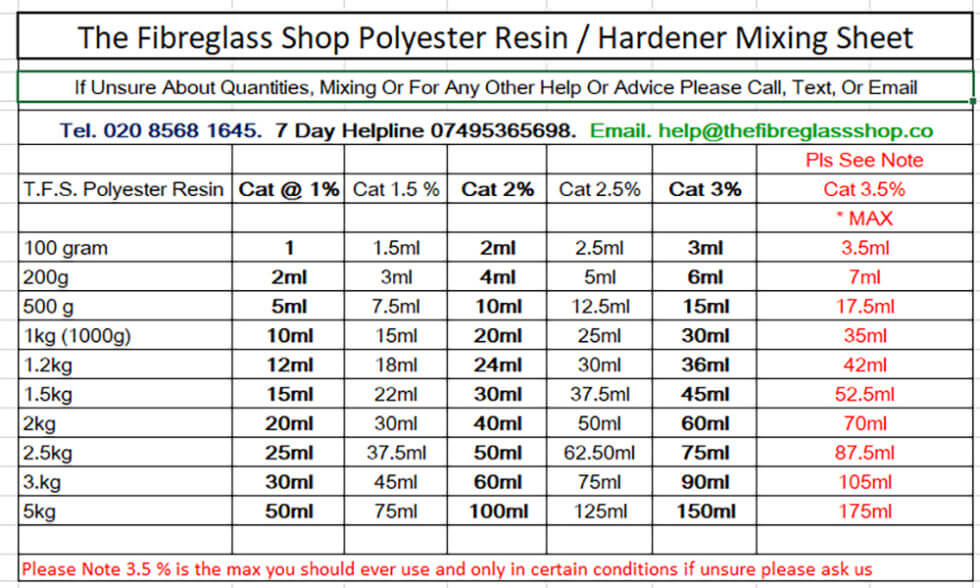

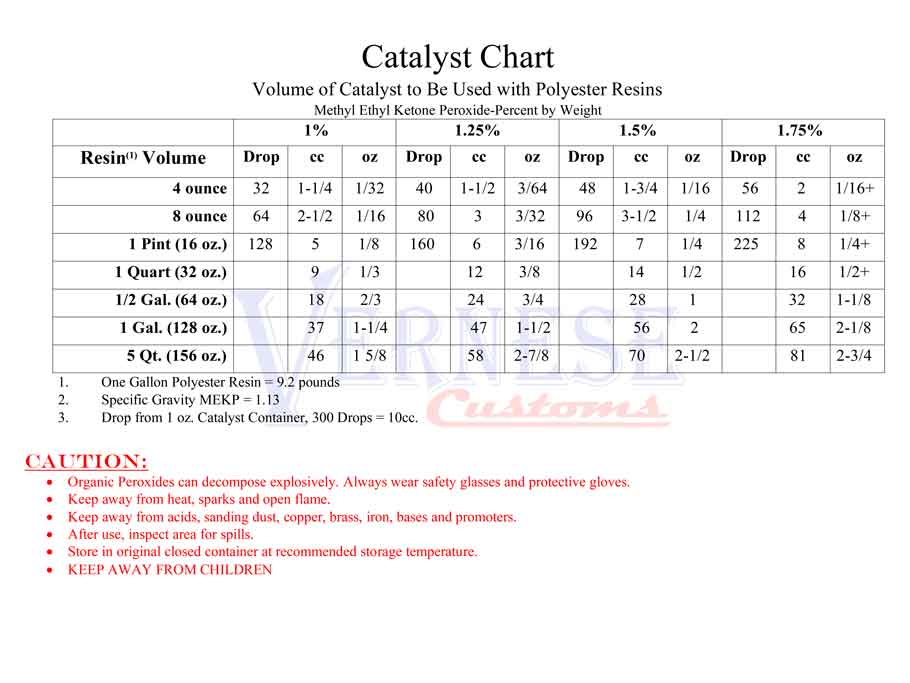

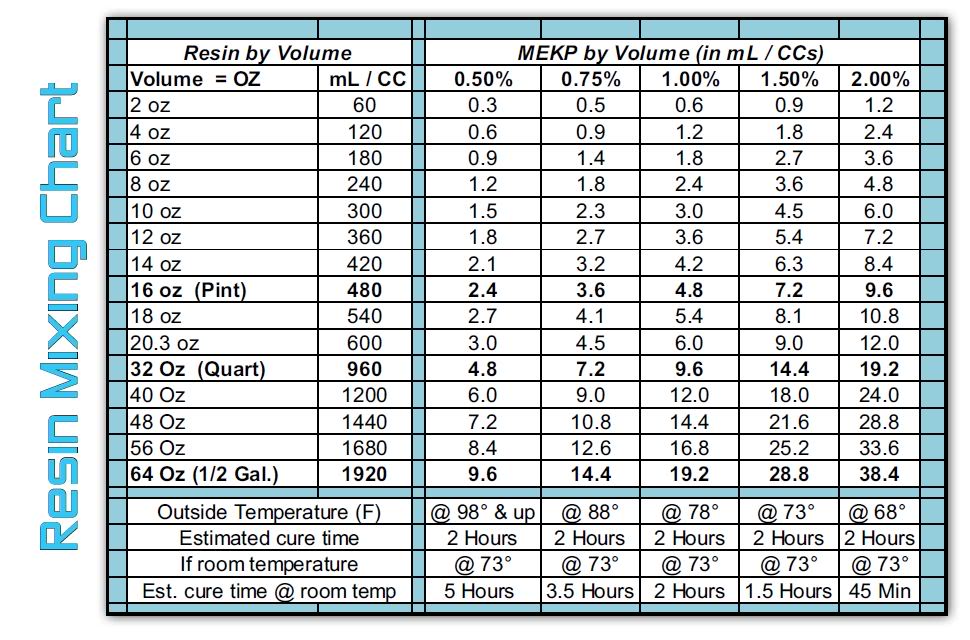

Polyester Resin Mix Ratio Chart - Web catalyst concentration & equivalent measure chart. Web polyester resins and additives; Web for a standard 1% catalyst ratio, use the following mix ratio chart: Web totalboat resin mix ratios, application temperatures, pot life, working times and cure times. Gelcoat, paint, pigment & tints; Below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin to. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin and vinylester resin systems including isothalic and gelcoat. It’s important to note that adding too much surface seal can weaken the final product so do not add. And epoxy resins are measured by volume. Use measuring cups specifically designed for resin mixing to ensure precise ratios of resin. Below are two free mekp calculators. Web totalboat resin mix ratios, application temperatures, pot life, working times and cure times. It pisses me off when manufacturers combine us and metric measurements. Polyester resins are commonly used with. “well, if you didn't have time to do it right, you sure didn't have time to do it twice.” jim swanson,. Web the catalysed polyester resin topcoat should be applied at a quantity of 0.5 kg per square meter of laminate. Below are two free mekp calculators. Web polyester resin/gelcoat is catalyzed with mekp (methyl ethyl ketone peroxide). Accurate measurement is crucial when mixing polyester resin. Web catalyst concentration chart m.e.k. Web catalyst large quantity chart. Web catalyst concentration chart m.e.k. Quantities of polyester resin topcoat are estimates and should. Web the catalysed polyester resin topcoat should be applied at a quantity of 0.5 kg per square meter of laminate. Use the following ratios for. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence of a catalyst and combined with glass fibre chopped strand matting (csm). It pisses me off when manufacturers combine us and metric measurements. Web the mixing ratio is specific to your resin brand, and this is dependent on the chemical composition of that. Web the ratio of resin and hardener needed to make epoxy resin does depend on the product you are using, and every different product should have the ideal mixing ratio stated on. Accurate measurement is crucial when mixing polyester resin. Web the mixing ratio is specific to your resin brand, and this is dependent on the chemical composition of that. Gelcoat, paint, pigment & tints; Use the following ratios for. It pisses me off when manufacturers combine us and metric measurements. Web for a standard 1% catalyst ratio, use the following mix ratio chart: Remember that larger castings will get hot during curing and it is essential to use a lower catalyst ratio for. Use measuring cups specifically designed for resin mixing to ensure precise ratios of resin. Web 53k views 2 years ago. Use the following ratios for. Remember that larger castings will get hot during curing and it is essential to use a lower catalyst ratio for. So read the instructions well. The ratio is approximately one ounce of hardener per gallon of resin. Web trojan fibreglass uses two methods for mixing ratios, all polyester and vinylester resins are measured by weight. Web the catalysed polyester resin topcoat should be applied at a quantity of 0.5 kg per square meter of laminate. Web 53k views 2 years ago. Web use milliliters its. Web the mixing ratio is specific to your resin brand, and this is dependent on the chemical composition of that specific brand of resin. It’s important to note that adding too much surface seal can weaken the final product so do not add. Web polyester resin is an excellent matrix material in the creation of fibreglass (grp) in the presence. It’s important to note that adding too much surface seal can weaken the final product so do not add. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin and vinylester resin systems including isothalic and gelcoat. Web generally speaking, for polyester resins, the mixing ratio is 2% i.e. Web the catalysed polyester resin topcoat should be. Web totalboat resin mix ratios, application temperatures, pot life, working times and cure times. Web polyester resin additive chart catalyst & wax solution. Remember that larger castings will get hot during curing and it is essential to use a lower catalyst ratio for. Web the mixing ratio is specific to your resin brand, and this is dependent on the chemical composition of that specific brand of resin. 100 ml at 1.5% is 1.5ml mepk etc. Web 53k views 2 years ago. The tables below display data for totalboat epoxy products and other resins. Web mek, short for mekp, is the “hardener” or catalyst for polyester resin and vinylester resin systems including isothalic and gelcoat. For the water clear casting polyester. It’s important to note that adding too much surface seal can weaken the final product so do not add. Accurate measurement is crucial when mixing polyester resin. And epoxy resins are measured by volume. Web catalyst concentration & equivalent measure chart. Web for a standard 1% catalyst ratio, use the following mix ratio chart: Web the catalysed polyester resin topcoat should be applied at a quantity of 0.5 kg per square meter of laminate. Web in the samples with polyester fibers, it was observed that the e value decreased by 0.24% in the sample with a fiber ratio of 0.25%, while the effect of 1.0% fiber ratio increased.

How to Apply Gelcoat by Brush and Roller How to Articles Bottom

Polyester Resin Mixing Ratio Chart

MEKP Chart and Calculators. Try for FREE! Vernese Customs®

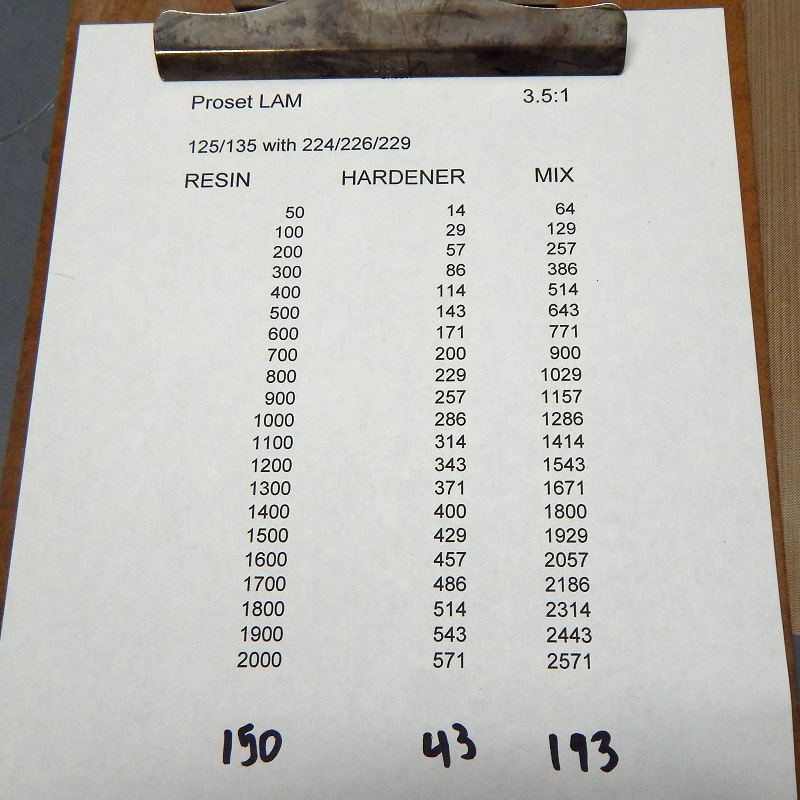

A&W Marine Resin mixing chart

MIX RATIO RESIN RESEARCH EPOXY shapehouse

Polyester Resin Mixing Ratio Chart

RESIN AMOUNT PER SURFBOARD and STAND UP PADDLEBOARD LENGTH CHART

General Purpose Polyester Fiberglass Resin Kit FGCI

Resin comparison chart Resin crafts, Epoxy resin diy, Diy resin art

Polyester Resin Mixing Ratio Chart

Below Are Two Free Mekp Calculators.

Quantities Of Polyester Resin Topcoat Are Estimates And Should.

Specific Gravity Mek Peroxide = 1.17 Polyester Resin= 1.09 Gelcoat = 1.3.

Web Generally Speaking, For Polyester Resins, The Mixing Ratio Is 2% I.e.

Related Post: