Polyiso Insulation R Value Chart

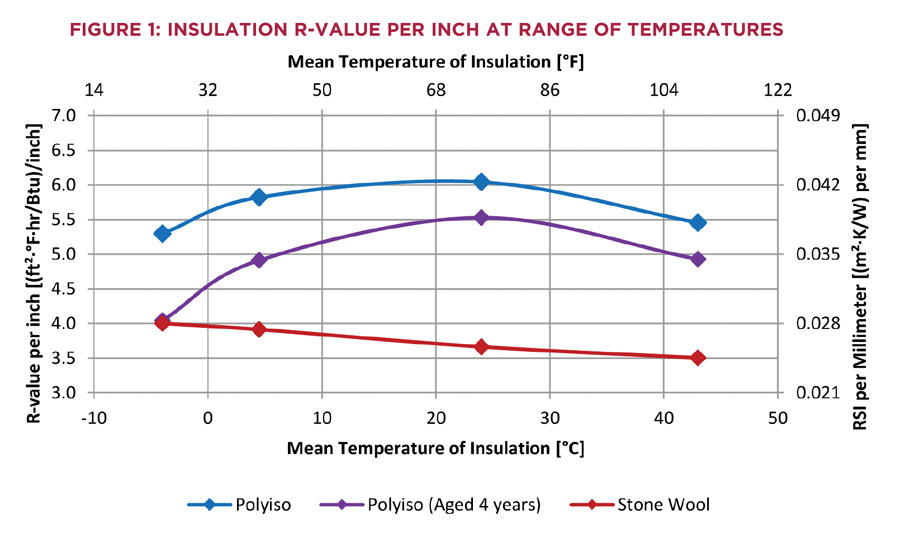

Polyiso Insulation R Value Chart - Because of its light weight, this material is easy to handle on the jobsite and installs quickly. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. Small air pockets visible in. Flat & tapered enrgy 3®. Green circle certified for recycled content. Polyiso insulation packaging & weight charts. In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Web closed cell polyisocyanurate foam core: Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Polyiso insulation packaging & weight charts. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. In roof. Web polyiso insulation packaging & weight charts. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Offers potential leed® credits for polyiso use. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. Web closed cell polyisocyanurate foam core: In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Web highest r value per inch compared to any other type of non polyiso insulation of equivalent thickness. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. Lightweight and easy to cut in. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. Polyiso insulation packaging & weight charts. Flat & tapered enrgy 3®. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. Offers potential leed® credits for polyiso use. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Green. Rsi values are given as well. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least 20%. Flat & tapered enrgy 3®. Because of its light weight, this material is easy to handle on the jobsite. This allows polyiso products to deliver more energy savings potential for buildings than other materials of the same thickness. Flat & tapered enrgy 3®. Small air pockets visible in. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. At this thickness, the advantage in thermal performance of polyiso over polystyrene is at least. Rsi values are given as well. Offers potential leed® credits for polyiso use. Offers various facers and compressive strength options depending on your specification needs. Web closed cell polyisocyanurate foam core: Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Web polyiso insulation packaging & weight charts. Web closed cell polyisocyanurate foam core: Rsi values are given as well. Offers potential leed® credits for polyiso use. Offers various facers and compressive strength options depending on your specification needs. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Rsi values are given as well. Flat & tapered enrgy 3®. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. Offers various facers and compressive strength options depending on your specification needs. Small air pockets visible in. Rsi values are given as well. Because of its light weight, this material is easy to handle on the jobsite and installs quickly. Lightweight and easy to cut in the field, making handling and installation easier and more efficient. Web polyiso insulation packaging & weight charts. In roof applications, permeable facers are preferred and the average thickness of foam used is 2 inches. Easy cutting in the field provides the installer with simplified fabricating on the roof deck. Green circle certified for recycled content. Offers various facers and compressive strength options depending on your specification needs. Web highest r value per inch compared to any other type of non polyiso insulation of equivalent thickness. Flat & tapered enrgy 3®. Polyiso insulation packaging & weight charts.

Polyiso Rigid Insulation R Value Chart

Gaf Polyiso R Value Chart

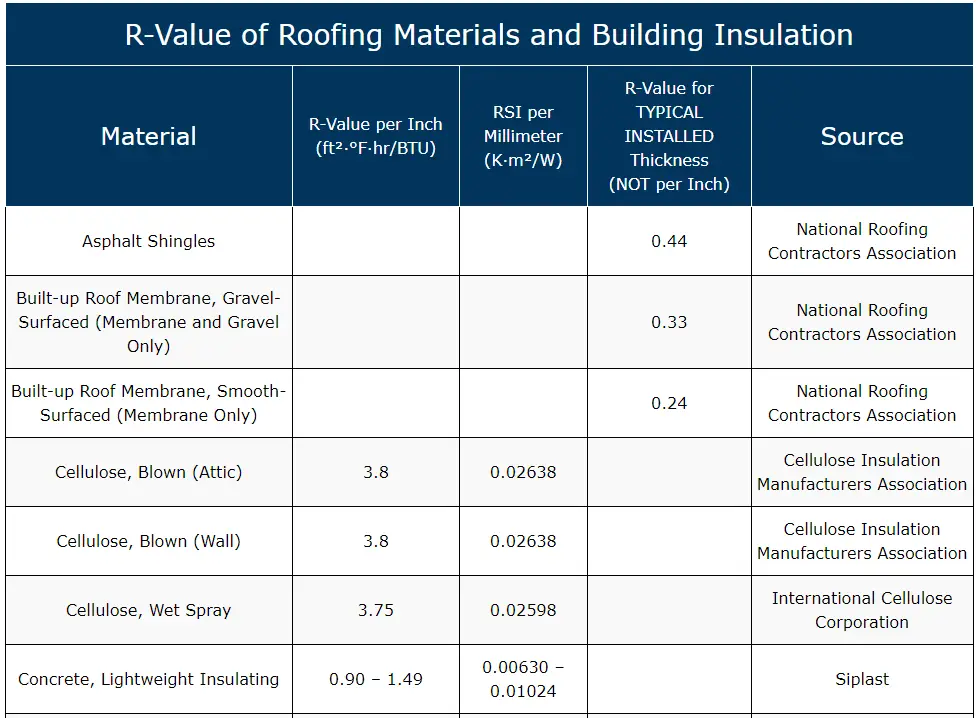

RValue Chart • 38 Types of Insulation & Roofing Materials

R Value Chart Insulation Types

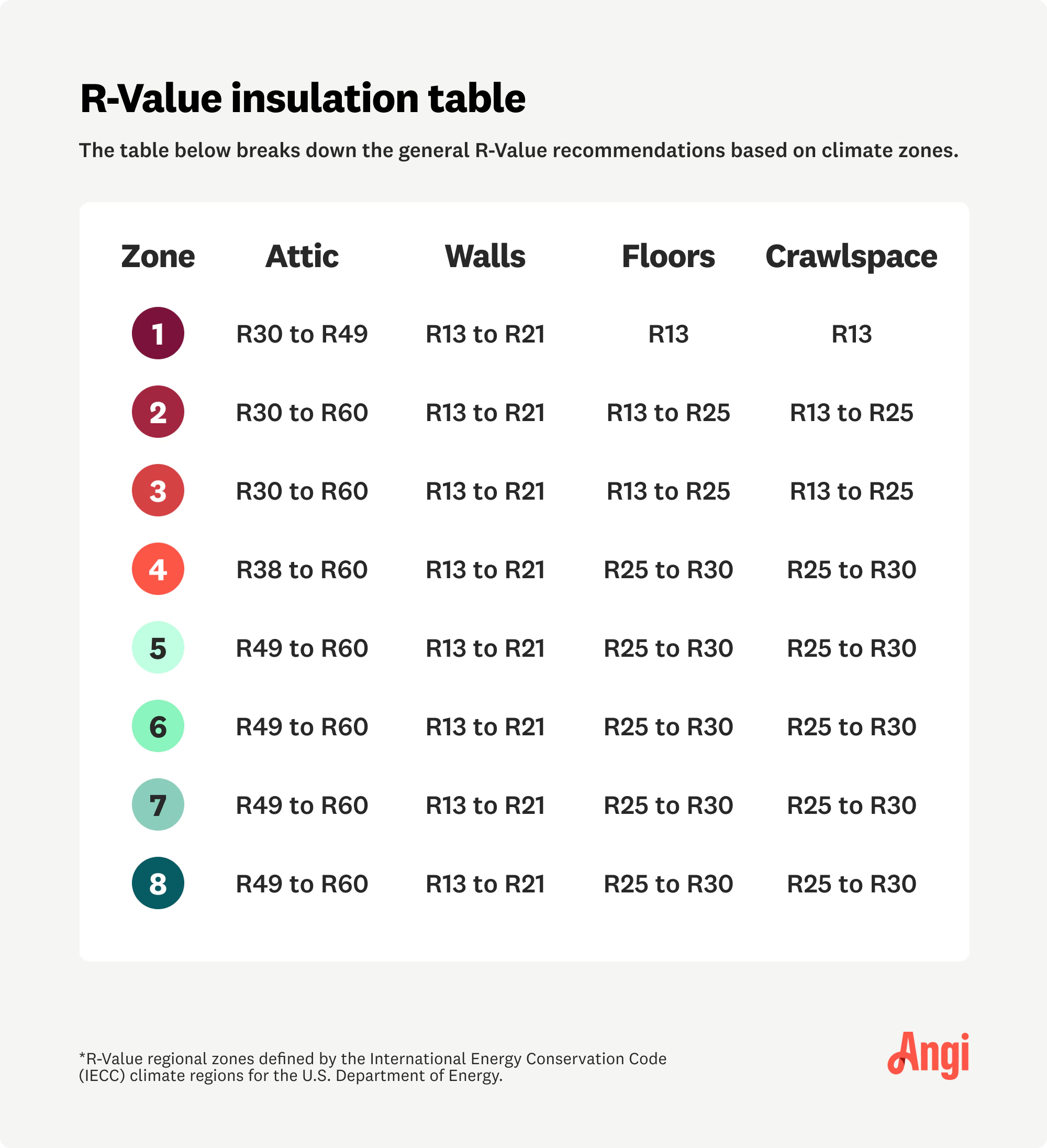

What Is RValue When It Comes to Insulation?

Polyiso R Value Chart

Gaf Polyiso R Value Chart

Polyiso Insulation Thickness RValue Chart Understanding RValue IKO

Understanding R values and building performance Green Home Guide

Polyiso Insulation R Value Chart

At This Thickness, The Advantage In Thermal Performance Of Polyiso Over Polystyrene Is At Least 20%.

Web Closed Cell Polyisocyanurate Foam Core:

This Allows Polyiso Products To Deliver More Energy Savings Potential For Buildings Than Other Materials Of The Same Thickness.

Offers Potential Leed® Credits For Polyiso Use.

Related Post: