Press Fit Bearing Tolerance Chart

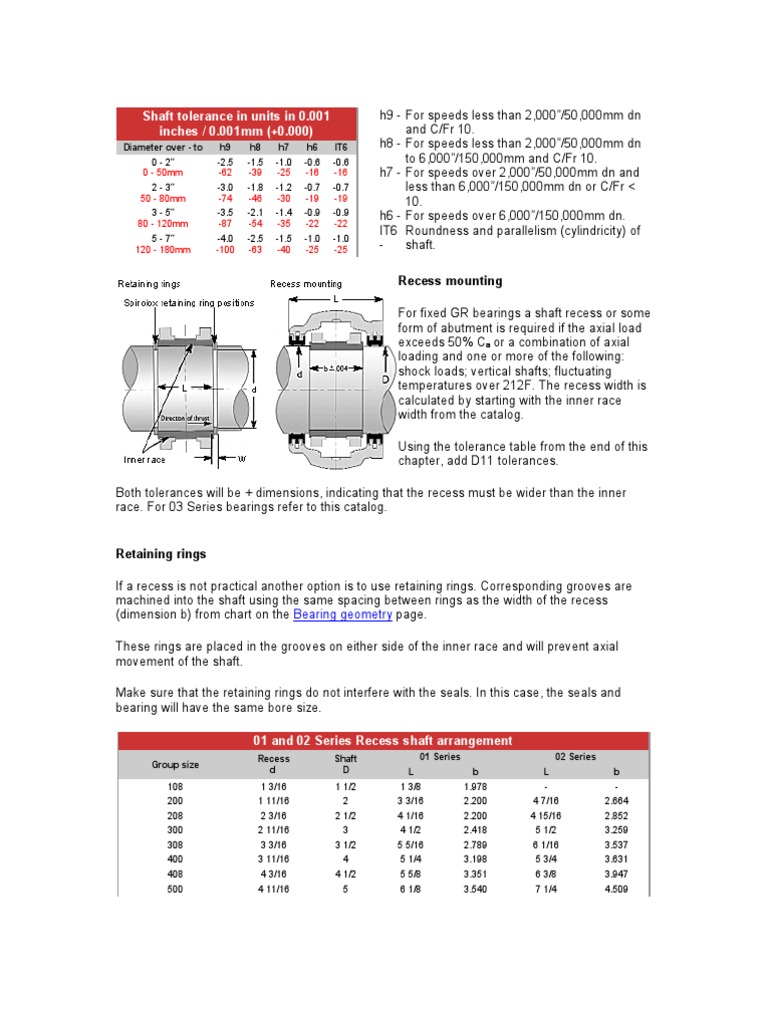

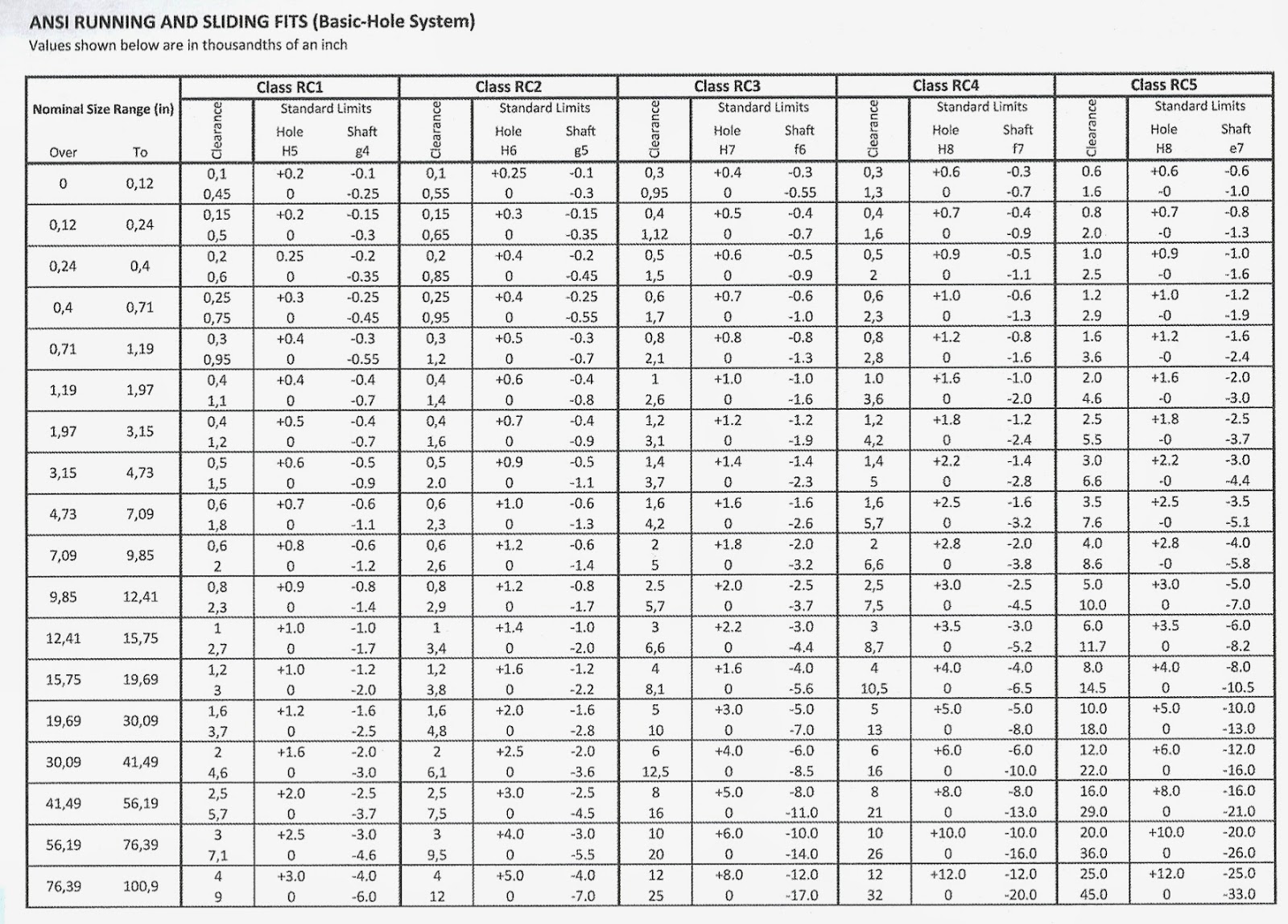

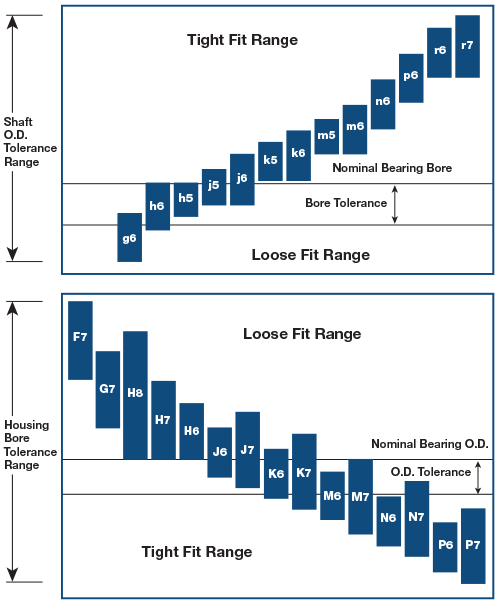

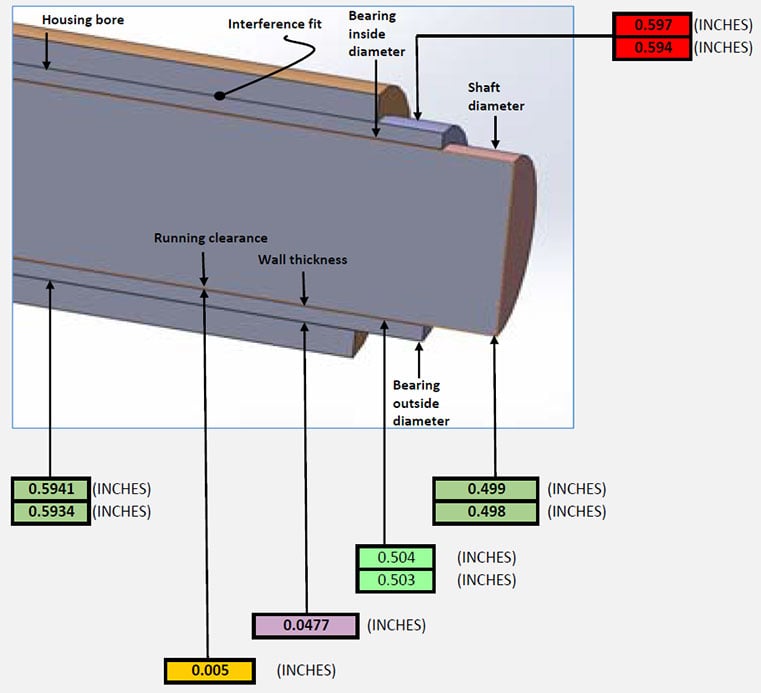

Press Fit Bearing Tolerance Chart - The bearing bore is smaller than your shaft diameter, or your bearing o.d. Web diameters greater than 3 inches, the outside diameters are designed 0.003 to 0.005 inch over the nominal size. Fits for thrust bearings table 7.4: Web these standards produce a consistent, uniform product. Go here, for explanasions about the terms hole, shaft, ei, and es. Go here, for explanasions about the terms hole, shaft, ei, and es. Find your data faster with our fits calculator. Web the tables in this section provide information about bearing tolerances, seat tolerances and resultant fits. Web complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Complete charts for h7/t6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Find your data faster with our fits calculator. Loose (slip), transition, and press (tight). Complete charts for r7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Web the tables in this section provide information about bearing tolerances, seat tolerances and resultant fits. Web widely used fits for class 0 tolerance bearings and. Web this calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. They are valid for standard applications but do not cover all details of a specific application. Web the tables in this section provide information about bearing tolerances, seat tolerances and resultant fits. These should enable you to determine easily. Compare the results with table i. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Find your data faster with our fits calculator. Web bearing fit is governed by the selection tolerances for bearing shaft. Find your data faster with our fits calculator. Loose (slip), transition, and press (tight). Complete charts for h7/p6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Web bearing fit is governed by the selection tolerances for bearing shaft diameters and housing bore diameters. These should enable you to determine easily the maximum. Compare the results with table i. Web the fit, or amount of interference that exists between mating components (such as the shaft and bearing bore), can be devised into three categories: Web the tables in this section provide information about bearing tolerances, seat tolerances and resultant fits. Skip to content your machining expert The bearing bore is smaller than your. Go here, for explanasions about the terms hole, shaft, ei, and es. To determine whether a load is either light, normal, or heavy, divide an application’s equivalent radial load (pr) by the bearing’s dynamic radial load rating (cr). Machined shaft and housings also have tolerance standards on their parts that range around 10µm. Go here, for explanasions about the terms. Complete charts for r7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Go here, for explanasions about the terms hole, shaft, ei, and es. Go here, for explanasions about the terms hole, shaft, ei, and es. Find your data faster with our fits calculator. The rpm adjustment factor is based on gmn. See page 44 for a definition and method for calculating equivalent radial load. The bearing bore is smaller than your shaft diameter, or your bearing o.d. Skip to content your machining expert Web widely used fits for class 0 tolerance bearings and various shaft and housing bore diameter tolerances are shown in fig. Loose (slip), transition, and press (tight). Check out our thermal range calculator to see how materials will grow and/or shrink when in operation. Web these standards produce a consistent, uniform product. Web basic size in milimeters. To determine whether a load is either light, normal, or heavy, divide an application’s equivalent radial load (pr) by the bearing’s dynamic radial load rating (cr). Web an interference fit. Compare the results with table i. Find your data faster with our fits calculator. The rpm adjustment factor is based on gmn ball bearing standards and our many years of bearing experience. Web basic size in milimeters. Go here, for explanasions about the terms hole, shaft, ei, and es. Web sliding fit driving fit press fit strong press fit shrinkage fit loose fit light roll fit roll fit 50 0 −50 −100 −150 −200 dimension tolerance h6 h7 200 150 100 50 0 −50 Web the fit, or amount of interference that exists between mating components (such as the shaft and bearing bore), can be devised into three categories: Go here, for explanasions about the terms hole, shaft, ei, and es. Loose (slip), transition, and press (tight). Web this article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical tips for optimal tolerance in press fit design. Web this calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Web complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. The bearing bore is smaller than your shaft diameter, or your bearing o.d. The rpm adjustment factor is based on gmn ball bearing standards and our many years of bearing experience. Web these standards produce a consistent, uniform product. Complete charts for h7/t6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Find your data faster with our fits calculator. Complete charts for h7/p6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Bearings have tolerance standards for the inner diameter (id) and the outer diameter (od). Web widely used fits for class 0 tolerance bearings and various shaft and housing bore diameter tolerances are shown in fig.

Press Fit Bearing Tolerance Chart

Press Fit Tolerance Chart

How to Determine Bearing Shaft and Housing Fit Baart Group

Too Tight or Perfect Fit? When to Use Press Fits in Your Assemblies

Tolerance Charts for Bearings — Electric Motor Bearings

Bearing Selection and Achieving the Right Press Fit

Bearing Press Fit Tolerance Chart

Bearing Tolerance Chart

Bearing Fit Chart Bearing (Mechanical) Engineering Tolerance

Tolerance Charts for Bearings — Electric Motor Bearings

Web An Interference Fit Is Precisely The Opposite Of The Clearance Fit.

Web Diameters Greater Than 3 Inches, The Outside Diameters Are Designed 0.003 To 0.005 Inch Over The Nominal Size.

Skip To Content Your Machining Expert

Fits For Radial Bearings Table 7.3:

Related Post: