Run Capacitor Sizing Chart

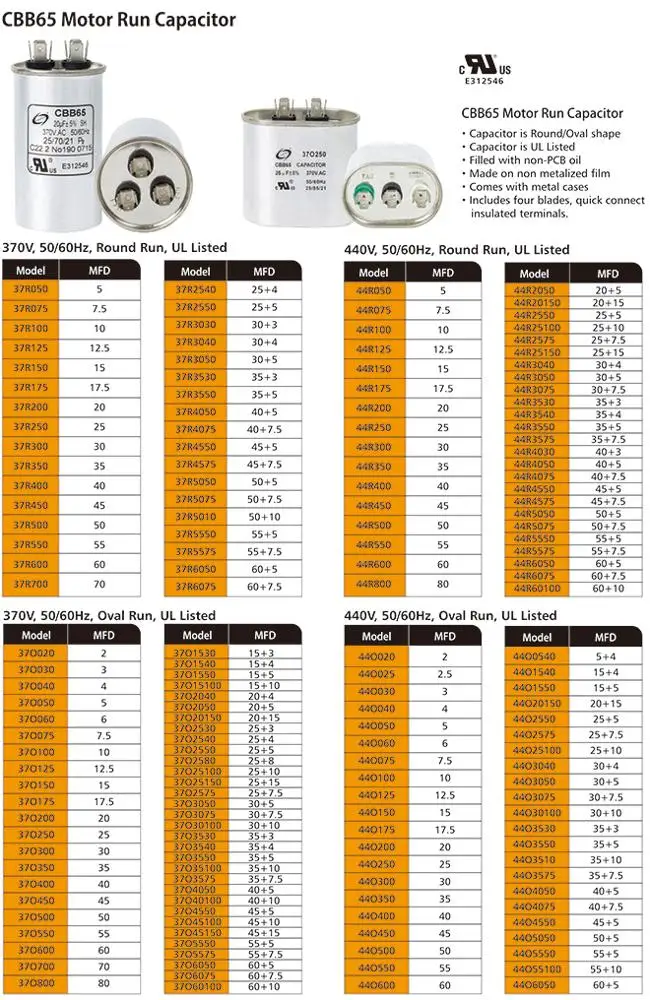

Run Capacitor Sizing Chart - The full load amps and voltage supply numbers should be readily available in the compressor’s manual. Web ipeak (a)= c ( f) * dv/dt (v/ μ. The parameters are capacitance, voltage rating, electrical frequency, operating temperature, and physical size. How do i calculate what size capacitor i need? Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Web here is a (somewhat) detailed article on motor run capacitors. In this hvac training vide. Web this article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to be installed. Below is a simplified diagram of the problem. Web how to quickly determine the capacitor size on an air conditioner to make sure that you are replacing it with the correct ratings! Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Run capacitors are also rated by voltage classification. Web single phase capacitor sizing. Web here is a (somewhat) detailed article. The web sites of capacitor sellers sometimes have tables of typical values based on power, voltage and frequency ratings. However, the exact sizing may vary based on the motor’s characteristics and manufacturer recommendations. These are two questions many compressor owners ask on this site. Well, it is supposed to. Desired” as corrected power factor has multiple advantages. However, the exact sizing may vary based on the motor’s characteristics and manufacturer recommendations. The voltage classifications are 370v and 440v. The converter converts 220 single phase to 240 3 phase. A series pumps (ams(x), ak(x), av(x)) grp series pumps. Web and how do you size the starter capacitor? How do i calculate what size capacitor i need? Web this article explains how to select an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to be installed. Web the basic formula. The parameters are capacitance, voltage rating, electrical frequency, operating temperature, and physical size. Web what is capacitance? When they are damaged they tend to drop in capacitance. Because it is designed for continuous duty, it has a much lower failure rate than a start capacitor. Web this article series explains how to choose & buy an electric motor start capacitor,. Run capacitors are also rated by voltage classification. Capacitors with ratings above 70 microfarad (uf) are starting capacitors. Web how to quickly determine the capacitor size on an air conditioner to make sure that you are replacing it with the correct ratings! Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Capacitors with. The web sites of capacitor sellers sometimes have tables of typical values based on power, voltage and frequency ratings. When install a motor using capacitor for starting or running methods,we must sizing the rated of capacitor suitable with motor to get correct starting torque and avoid winding from overheating and can cause a damage. However, the exact sizing may vary. How to calculate the capacitor size? Then, divide this number by the overall voltage supply for your compressor. Enter motor power in watts: The full load amps and voltage supply numbers should be readily available in the compressor’s manual. Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Below is a simplified diagram of the problem. How do i calculate what size capacitor i need? Run capacitors are also rated by voltage classification. The preferable method would be to search the brand and model number to see if you can find detailed information from the manufacturer. Run capacitors are designed for continuous duty, and are energized the entire. I constructed a rotary phase converter from a 5 hp motor. What size capacitor do i need? Capacitors with ratings above 70 microfarad (mfd) are starting capacitors. Run capacitors are designed for continuous duty, and are energized the entire time the motor is running. Capacitors with ratings above 70 microfarad (uf) are starting capacitors. Web this article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to be installed. What size of capacitor do i need? Web and how do you size the starter capacitor? Web the basic formula for sizing a run capacitor is approximately 0.1 to 0.2 μf per horsepower, and for a start capacitor, it’s around 100 to 200 μf per horsepower. Web how motor capacitors are specified. There's no set size of capacitor for given horse power, it varies by manufacturer and design. Verify that your selected capacitor has at least the number of connection terminals per connection post as the original motor capacitor. Run capacitors are designed for continuous duty, and are energized the entire time the motor is running. Motor capacitors are specified using five parameters, with four typically listed on a label (figure 4). Web this article explains how to select an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an ac compressor motor or fan motor where the capacitor is to be installed. I wired up the circuit exactly how is done below: How to calculate the capacitor size? These are two questions many compressor owners ask on this site. Below is a simplified diagram of the problem. The voltage classifications are 370v and 440v. Enter motor power in watts:

Single Phase Motor Capacitor Sizing Chart

Run Capacitor Size Chart

Capacitors Conversion Chart GaliGear Australia Electronics & Home

Motor Capacitor Sizing Chart Transborder Media

Capacitor Sizing Chart For Motor

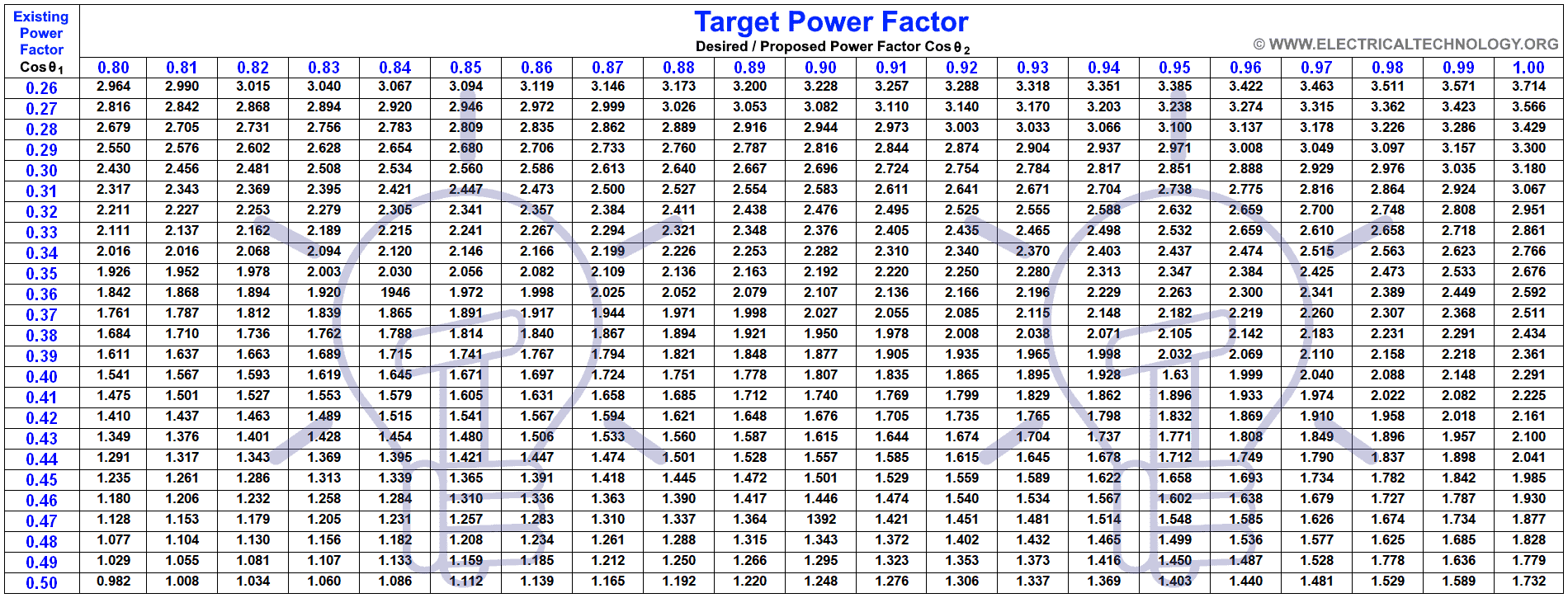

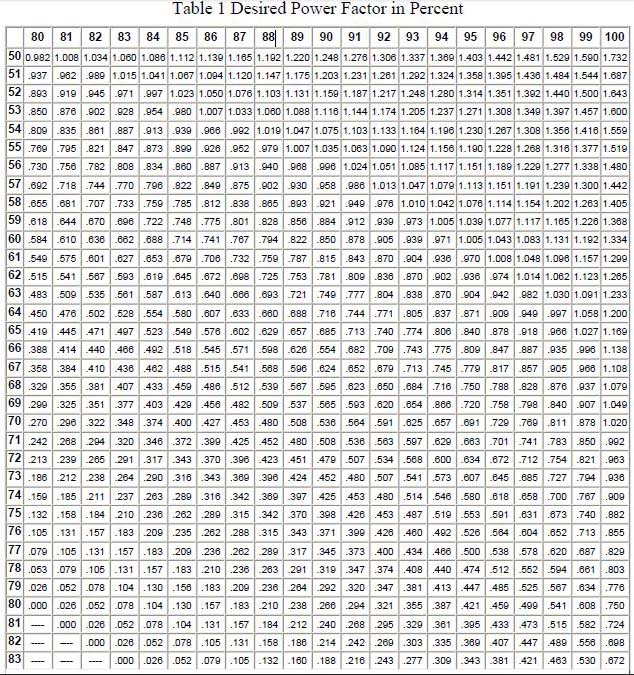

Power Factor Correction Capacitors Sizing Calculations Part Eleven

Run Capacitor Size Chart

Capacitor sizing for power factor correction Electrical Engineering

Motor Run Capacitor UL capacitor AC capacitor CBB65 Products from Long

Run Capacitor Size Chart

I Am Getting Some Very Odd Results That I Am Wondering If Someone Can Help Explain.

The Converter Converts 220 Single Phase To 240 3 Phase.

Run Capacitors Are Also Rated By Voltage Classification.

Because It Is Designed For Continuous Duty, It Has A Much Lower Failure Rate Than A Start Capacitor.

Related Post: