Snap Tie Spacing Chart

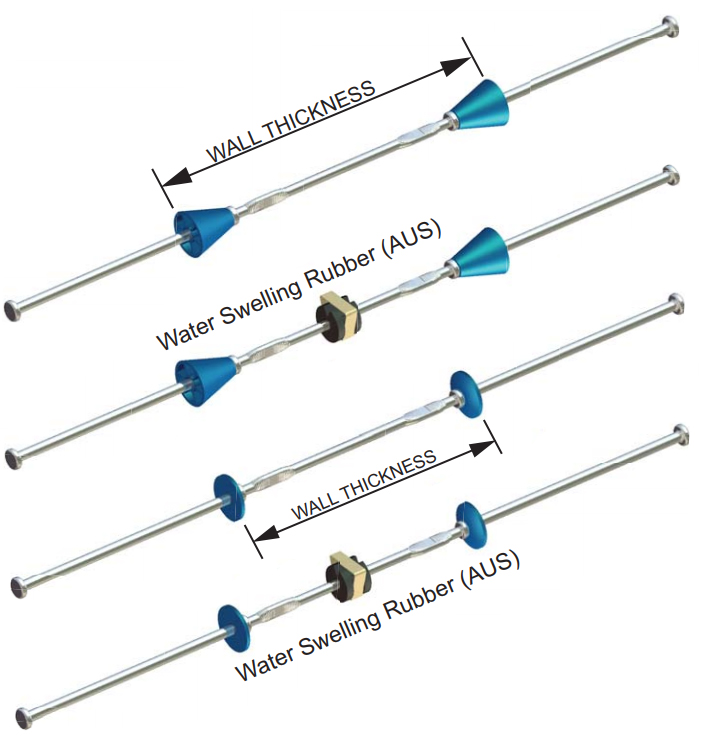

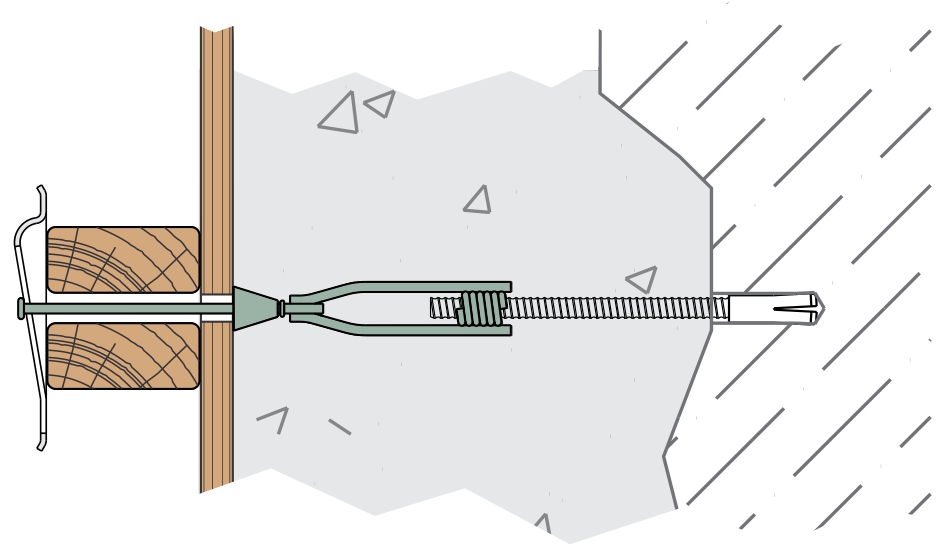

Snap Tie Spacing Chart - Made with 1” x 1” plastic cones. Refer to the back cover for addresses and phone numbers. Form board design by others. The tables give spacing guidelines for various form heights and types of form boards. S = (wht) / (l*p) where: Loose washer ties or 1” x 1” cone tie. Pour pressure of 450 psf with l/360 defl ection. Web october 11, 2023 by gegcalculators. Web the recommended spacing for these ties typically depends on the dimensions of the vertical and horizontal elements. Too much space allowed between the wales may cause crushing of the wales and/or the bending of the wedge allowing the form to bulge outward. Web drill holes in plywood 1/8 larger than the snap tie head. Hex head measures 1/2” across flats. S = (w * h * t) / (l * p) where: Web when using snap ties, correct spacing between double wales is 5/8 to 3/4. Web • ties are ordered based on wall thickness • space ties from the top 1’,3’,. Web the most common snap tie spacings being used with the jahn forming system are shown below. If you are looking to save money by pouring your own concrete for your. The most common snap tie spacings being used with the jahn forming system are shown below. Web this diagram is based on: Pour pressure of 750 psf with l/360. S represents the snap tie spacing, which is the distance between individual snap ties along a concrete form. S is the snap tie spacing; A 1/2″ breakback is available on special order. For different rates or pour and/or other tie spacing, contact masons supply. Other sizes available upon request. For taller walls, closer spacing is required, such as 4 to 6 inches for walls between 4 to 8 feet high. Refer to the back cover for addresses and phone numbers. Web correct spacing between double wales is 5/8 to 3/4 jahn® a bracket is utilized to hold a single wale and can be installed before or after the wales. Drill holes in plywood 1/8 larger than the snap tie head (usually 5/8 diameter drill bit will be required 2. Place the ends of snap ties through the holes in the plywood 3. If you are looking to save money by pouring your own concrete for your. Web october 11, 2023 by gegcalculators. Because of high tension stress, 100% breakback. Pour pressure of 450 psf with l/360 deflection. Normally, a 5/8 drill bit is sufficient. In general, the higher the form is, the closer the spacing of the wts should be. Web the most common snap tie spacings being used with the jahn forming system are shown below. Other sizes available upon request. 3/4” plywood thickness, face grain perpendicular to walers. Pour pressure of 750 psf with l/360 deflection with 12” spacing. For taller walls, closer spacing is required, such as 4 to 6 inches for walls between 4 to 8 feet high. Pour pressure of 450 psf with l/360 defl ection. These fillers require wall tie connections to For different rates or pour and/or other tie spacing, contact masons supply. Place the bracket (jahn® a, jahn® c or omni wedge) on the tie 4. Refer to the back cover for addresses and phone numbers. If you are looking to save money by pouring your own concrete for your. Web snap tie concrete forms are a simple and effective. S represents the snap tie spacing, which is the distance between individual snap ties along a concrete form. S = (w * h * t) / (l * p) where: Web when using snap ties, correct spacing between double wales is 5/8 to 3/4. Drill holes in plywood 1/8 larger than the snap tie head (usually 5/8 diameter drill bit. A 1/2″ breakback is available on special order. Web coating the tie ends with wax will aid in breakback operation. This spacing allows for proper support and reinforcement during the concrete pouring process. For taller walls, closer spacing is required, such as 4 to 6 inches for walls between 4 to 8 feet high. If you are looking to save. Web • ties are ordered based on wall thickness • space ties from the top 1’,3’, 5’, 7’ then 1’ o.c. Please call for lead time, pricing, and availability. 5,050,365 standard breakback is 13/16”. 3/4” plywood thickness, face grain perpendicular to walers. S = (w * h * t) / (l * p) where: Standard 16” waler spacing with 2x4 lumber. S represents the snap tie spacing, which is the distance between individual snap ties along a concrete form. The snaptie is available equipped with either plastic spreader cones or loose metal washers. The most common snap tie spacings being used with the jahn forming system are shown below. Place the bracket (jahn® a, jahn® c or omni wedge) on the tie 4. These fillers require wall tie connections to This spacing allows for proper support and reinforcement during the concrete pouring process. Web snaptie spacing and rate placement: Web the most common snap tie spacings being used with the jahn forming system are shown below. This results in incorrect wall thickness and causes the tie spreader washers or cones to become embedded and trapped in the. Refer to the back cover for addresses and phone numbers.

SC Snap Coil Ties — Steel Dog

Snap Tie Spacing Chart

Concrete Snap Tie Spacing

Snap Tie Spacing Calculator Online

SnapCoil™ Tie — Steel Dog

Scaffolding Federal OSHA Tie Spacing DH Glabe & Associates

Custom Ties — Steel Dog

Snap Tie Spacing Chart

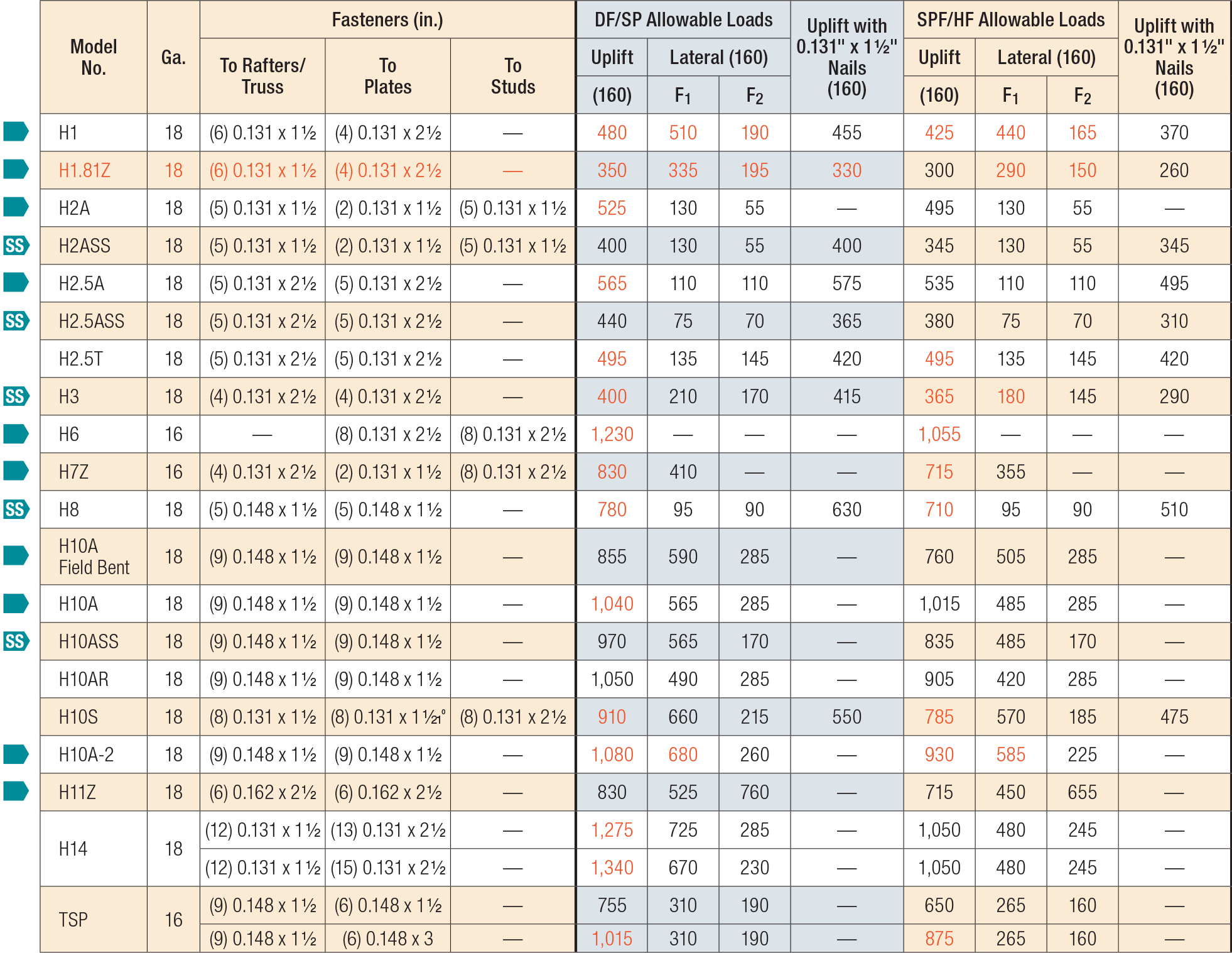

H Hurricane and Seismic Ties Simpson StrongTie

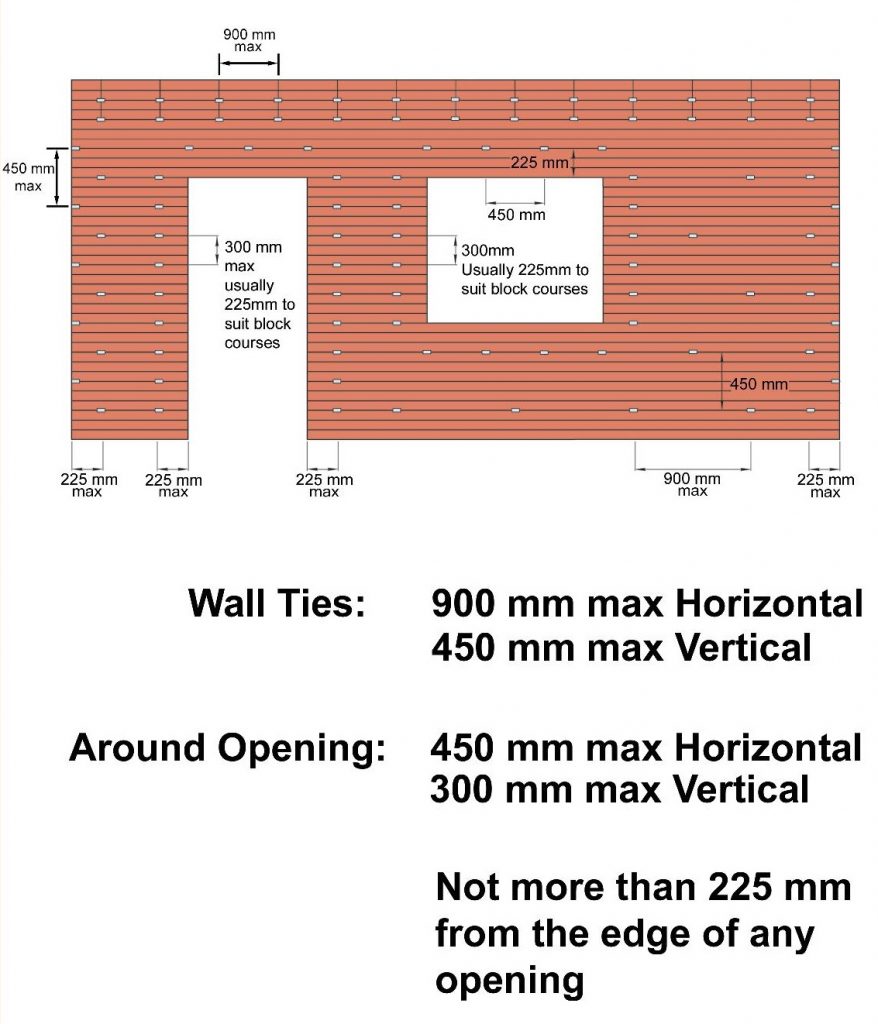

What is standard wall tie spacing? Wonkee Donkee Tools

S Is The Snap Tie Spacing;

For Taller Walls, Closer Spacing Is Required, Such As 4 To 6 Inches For Walls Between 4 To 8 Feet High.

Other Sizes Available Upon Request.

Place The Ends Of Snap Ties Through The Holes In The Plywood 3.

Related Post: