Stainless Steel Filler Rod Chart

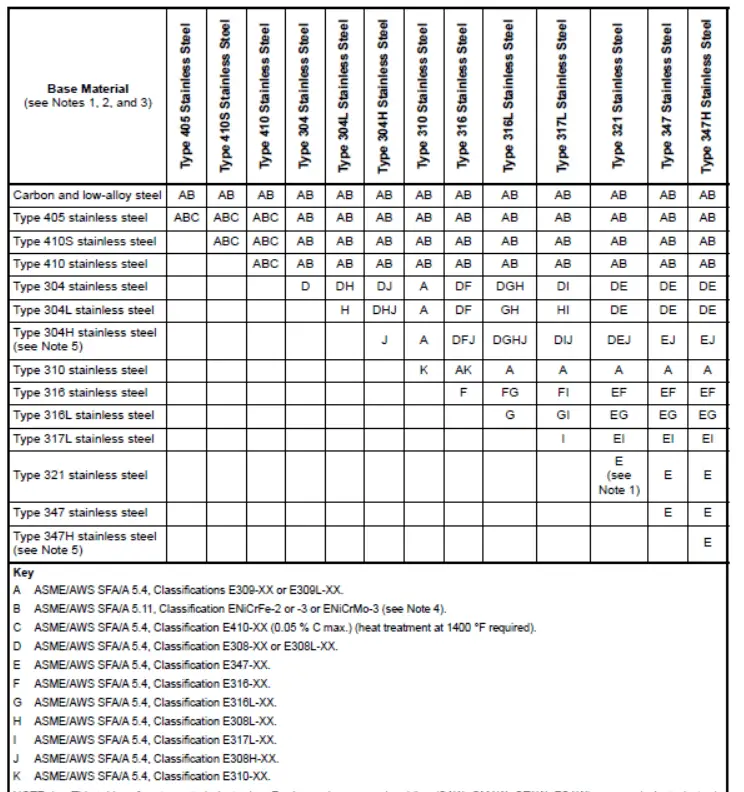

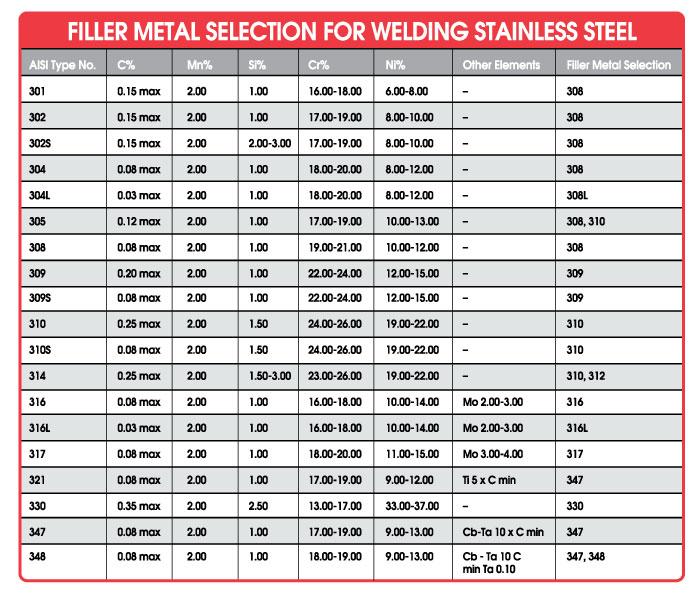

Stainless Steel Filler Rod Chart - Compare the compatibility of different filler metals with various stainless steel grades in a table format. Web stainless steel dissimilar welding chart. Web learn about different types of filler rods used in tig welding, such as mild steel, stainless steel, low alloy steel, copper alloy and aluminum. Bulger, secretary american welding society r. It’s the choice for tig welding 304 stainless steel, which is widely used in manufacturing. Web welding electrode selection chart for carbon steel to stainless steel, all stainless steel. Mig wires / tig rods (gmaw/gtaw). Wehr, vice chair arcos industries llc j. These charts and explanations help demonstrate the key differences between classifications, and provide insight into other optional designators, which can be equally important to. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Find out how to select, use, and control the properties of tig filler rods for various welding scenarios. E indicates electrode for arc welding. Web learn how to select the best filler metal for different types of stainless steel and welding processes. Eureka welding alloys manufactures high quality. Excellent strength and ductility, use as replacement for 15. Web a 316l filler metal is the appropriate choice for welding 316 austenitic stainless steels. Find out the characteristics, properties and challenges of welding stainless steel and how to optimize your results. The below chart gives very detailed guidelines for stick welding (smaw) or equivalent tig/mig filler wires for different types. Web learn about the five types of stainless steel and how to choose the right filler metal for each one. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. E indicates electrode for arc welding. What do you know about the metallurgy of stainless steel? Used for welding dissimilar metals. Web learn about different types of filler rods used in tig welding, such as mild steel, stainless steel, low alloy steel, copper alloy and aluminum. This does not mean the other filler metal alloys are not recommended or of less quality. Web the welding rod electrode identification system for smaw stainless steel is set up as follows: F number chart. Excellent strength and ductility, use as replacement for 15. Web a 316l filler metal is the appropriate choice for welding 316 austenitic stainless steels. One of the most common welding rods. This does not mean the other filler metal alloys are not recommended or of less quality. Tungsten size filler rod size cup size. Excellent strength and ductility, use as replacement for 15. This chart is only a suggestion of which filler metals should be adequate for the joining of the stainless steels. Midalloy 316lmn will join type 201, 304l, 316l, as well as 3% and 9% nickel alloy steels. See charts for standard and less common rods, including titanium, and tips for welding. Aluminium (achf) shield gas flow metal guage. F number chart in welding for carbon steel welding electrodes. Used for welding dissimilar metals. In all instances the chart should be used as a reference only. Web filler metal selector guide tool & die alloys cobalt alloys. Web f number for e309l, e308l, and other austenitic stainless steel welding consumables is 4. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Excellent strength and ductility, use as replacement for 15. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Web aws. Find out how to select, use, and control the properties of tig filler rods for various welding scenarios. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Excellent strength and ductility, use as replacement for 15. Gupta, secretary american welding society t. Download pdf version of this chart view chart for stick welding electrodes The below chart gives very detailed guidelines for stick welding (smaw) or equivalent tig/mig filler wires for different types of stainless steel welding. E indicates electrode for arc welding. For welding a carbon steel valve or bracket to an austenitic stainless steel tube or pipe (a common industry practice), a 309 grade filler metal should be used. F number chart. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web find the best filler metal for welding stainless steel based on aisi type number and preheat requirements. Aluminium (achf) shield gas flow metal guage. Kotecki, chair damian kotecki welding consultants f. Mig wires / tig rods (gmaw/gtaw). Find out the characteristics, properties and challenges of welding stainless steel and how to optimize your results. For welding a carbon steel valve or bracket to an austenitic stainless steel tube or pipe (a common industry practice), a 309 grade filler metal should be used. Denault esab specialty alloys t. Web learn about the five types of stainless steel and how to choose the right filler metal for each one. Web the welding rod electrode identification system for smaw stainless steel is set up as follows: Download pdf version of this chart view chart for stick welding electrodes Tig rods, metal cored wire and micro tig rods eureka 1216 (a.i.s.i. What do you know about the metallurgy of stainless steel? Web a 316l filler metal is the appropriate choice for welding 316 austenitic stainless steels. See charts for standard and less common rods, including titanium, and tips for welding settings and techniques. Deloach jr, 2nd vice chair naval surface warfare center r.

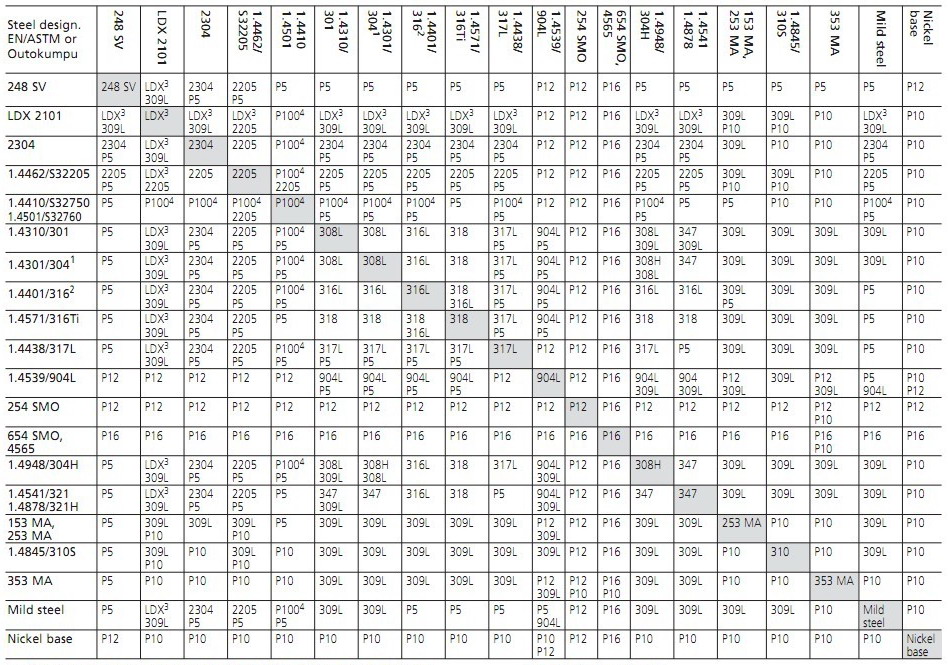

Filler Metals For Welding Stainless Steel LDX2101 S32205 2304 254SMO

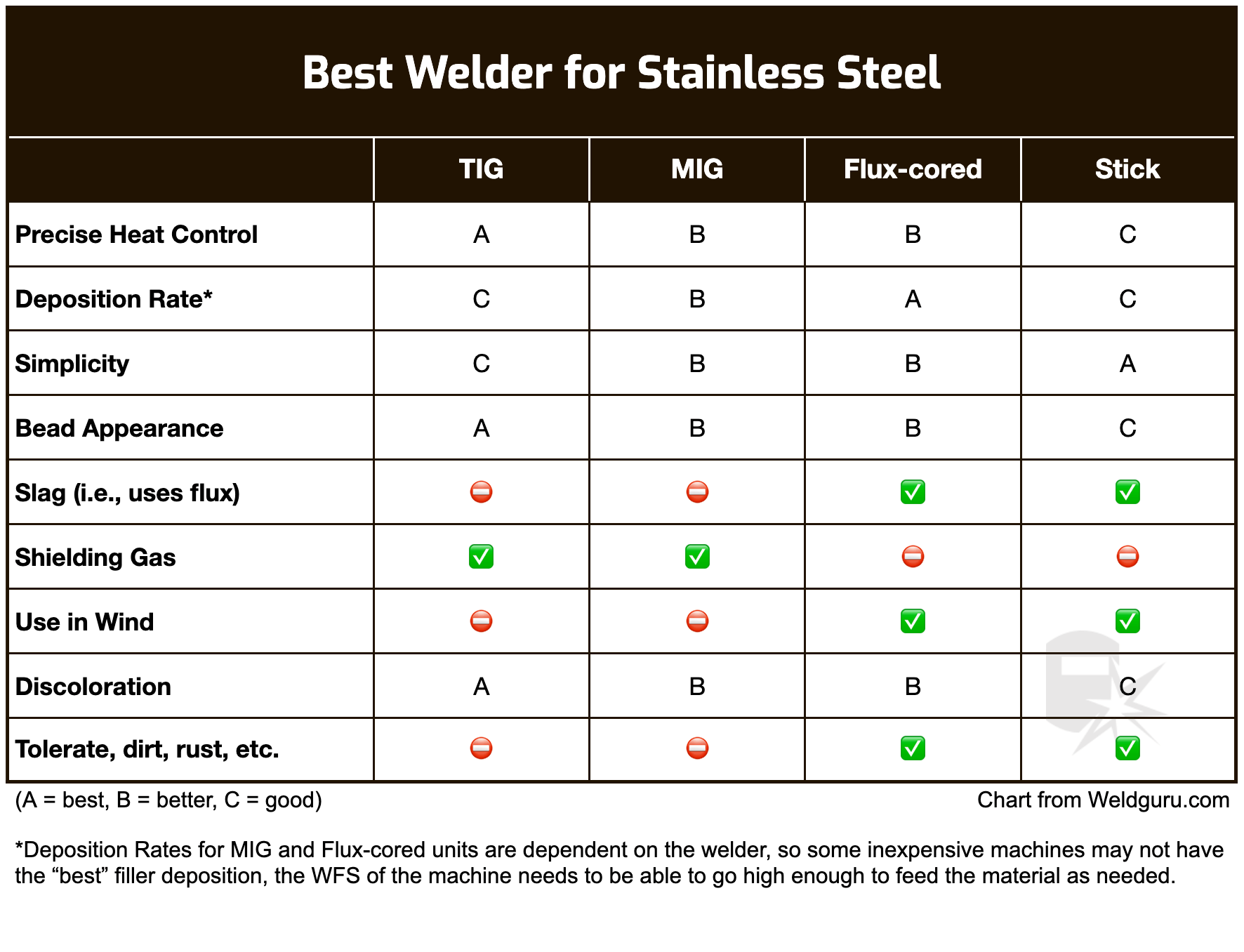

How To Stick Weld Stainless Steel

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Welding Electrode and Filler wire Selection Charts

Stainless Steel Filler Rod Chart

How to Weld Stainless Steel A Complete Guide

Tig Filler Rod Chart Stainless

Welding austenitic stainless steel

Stainless Steel Filler Rod Chart

Tig Filler Rod Sizes

Excellent Strength And Ductility, Use As Replacement For 15.

Anderson Esab Welding & Cutting Product J.

Midalloy 316Lmn Will Join Type 201, 304L, 316L, As Well As 3% And 9% Nickel Alloy Steels.

One Of The Most Common Welding Rods.

Related Post: