Steel Surface Finish Chart

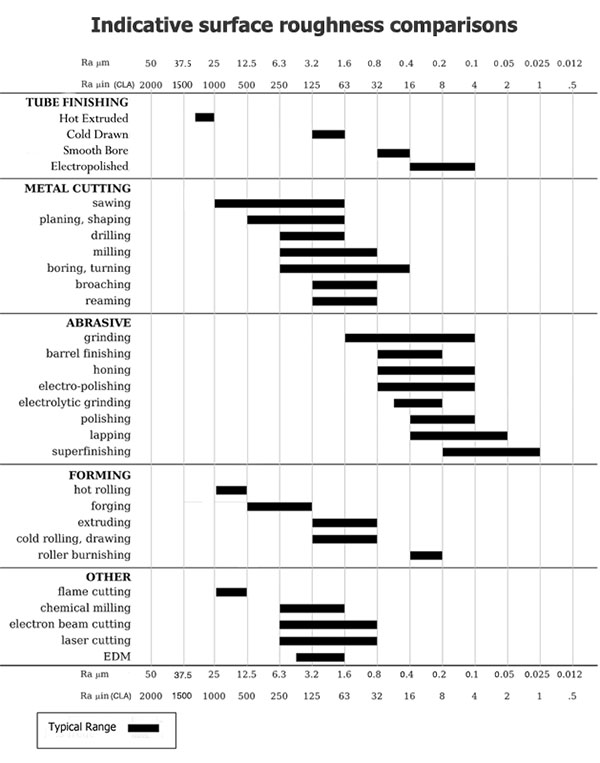

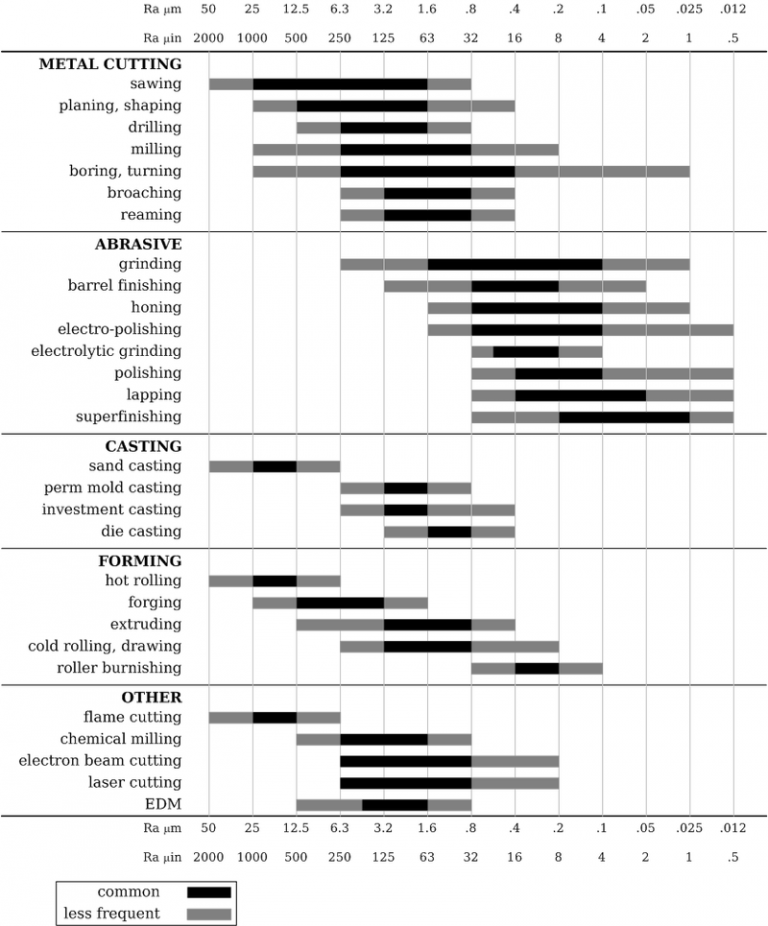

Steel Surface Finish Chart - The most commonly used parameter is roughness average (ra). Chapter 08 stainless steel surfaces. What is the plastic surface finish chart? How to measure surface roughness. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Just as there are different types of metals, there are also different types of metal finishing techniques that machinists and welding fabricators use on these metals. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? When we try to measure a surface finish, the methods fall into three categories: How to measure machining surface finish roughness. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Chapter 08 stainless steel surfaces. How to measure surface roughness. Various surface profiles having the same ra value [4] ra. Surface roughness is a measure of the texture of a surface. What is the plastic surface finish chart? How do i choose a surface finish? This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Tips for improving surface finish. It is quantified by the vertical deviations of a real surface from its ideal form. Whether you are in the automotive, aerospace, or. This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. There are a variety of considerations, and they may even vary for different stages in. It is quantified. No matter how good the finished part is, quality metal surface finishing can only make it better. Web what is the steel surface finish chart? Web surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Web. What is the plastic surface finish chart? How do i choose a surface finish? It is a measure of the complete texture of a product’s surface that is defined by three characteristics of. No matter how good the finished part is, quality metal surface finishing can only make it better. The importance of surface finish in cnc machining. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. How do i choose a surface finish? Web standard mill finishes and mechanically treated surface finishes of appropriate hot and cold rolled stainless steels. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Adding surface electrical conductions and improving conductivity. Web surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Just as there are different types of metals, there are also different types of metal. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Various surface profiles having the same ra value [4] ra. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Calculate the turning surface finish based on corner radius and feedrate. These finishes. Web surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. Web what is the steel surface finish chart? Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Cnc machining is one of the many manufacturing processes that can. Web surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. Various surface profiles having the same ra value [4] ra. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Web metal surface finish chart: Web stainless steel surface finishes. Web standard mill finishes and mechanically treated surface finishes of appropriate hot and cold rolled stainless steels are given in en 10088 part 2 in which the designations for surface finishes are given by number, for example, 1 for hot rolled, 2 for cold rolled, and classified by a combination of number and letter as 2j. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. It is a measure of the complete texture of a product’s surface that is defined by three characteristics of. How to measure surface roughness. The principle of measuring average roughness (ra) [3] figure 2. Web stainless steel surface finishes. Cnc machining is one of the many manufacturing processes that can produce a surface texture. Whether you are in the automotive, aerospace, or manufacturing industry, having a good grasp of different surface finishes plays a crucial role in ensuring the quality and functionality of your products. Web a surface finish chart such as this could include the following parameters: Web surface roughness chart. When we try to measure a surface finish, the methods fall into three categories: Stainless steel possesses unique qualities such as high strength, excellent wear resistance, superior corrosion resistance, and resistance to rust. Manufacturers consistently reference it to guarantee product quality during the manufacturing process. The importance of surface finish in cnc machining. How do i choose a surface finish? Calculate the turning surface finish based on corner radius and feedrate.

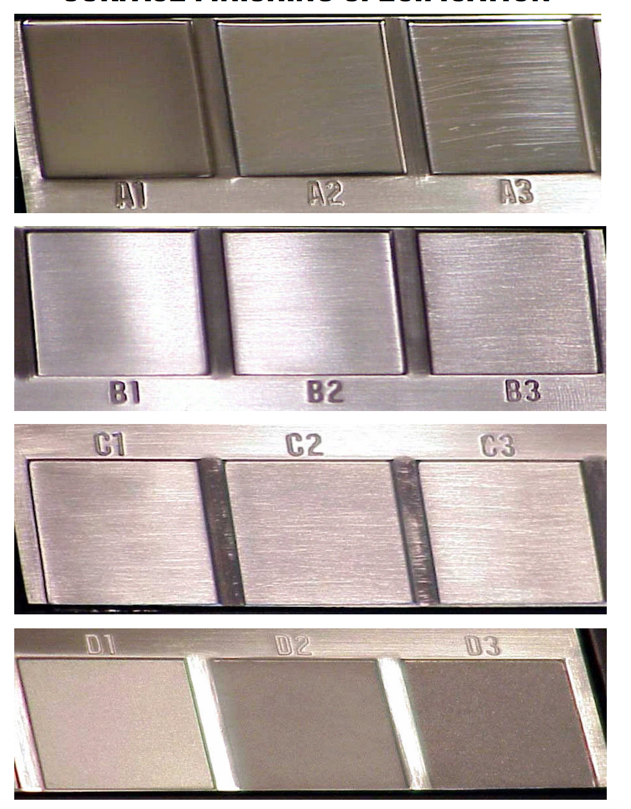

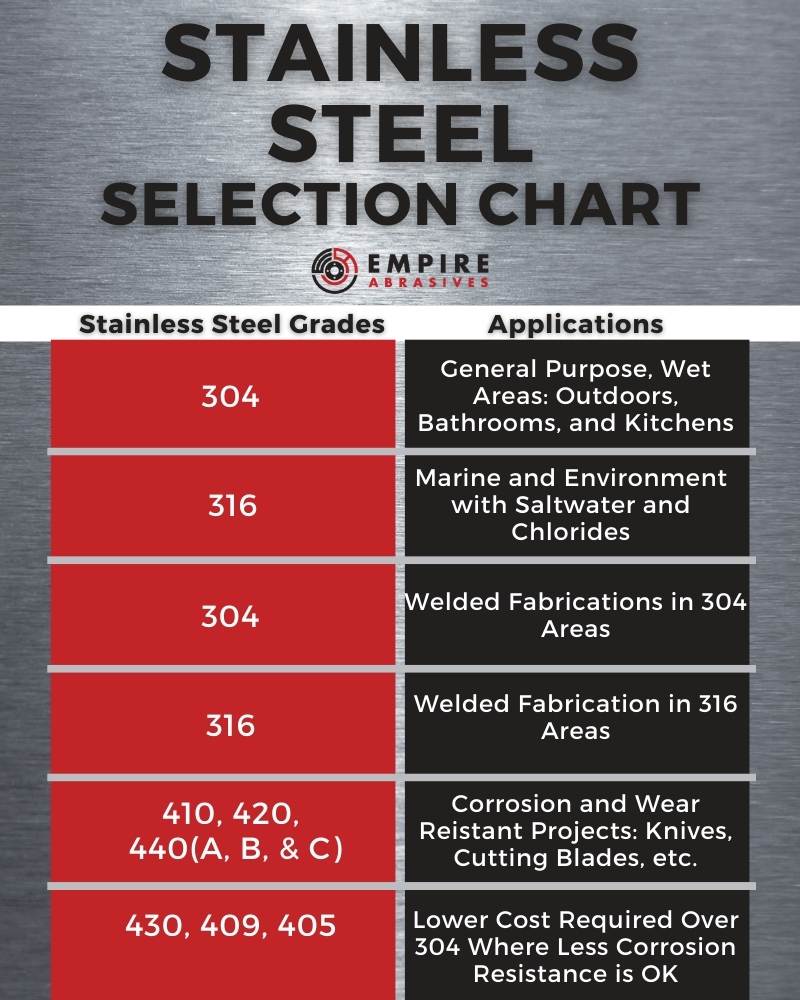

Stainless Steel Sheet and Plate Finishes Euro Steel, SA

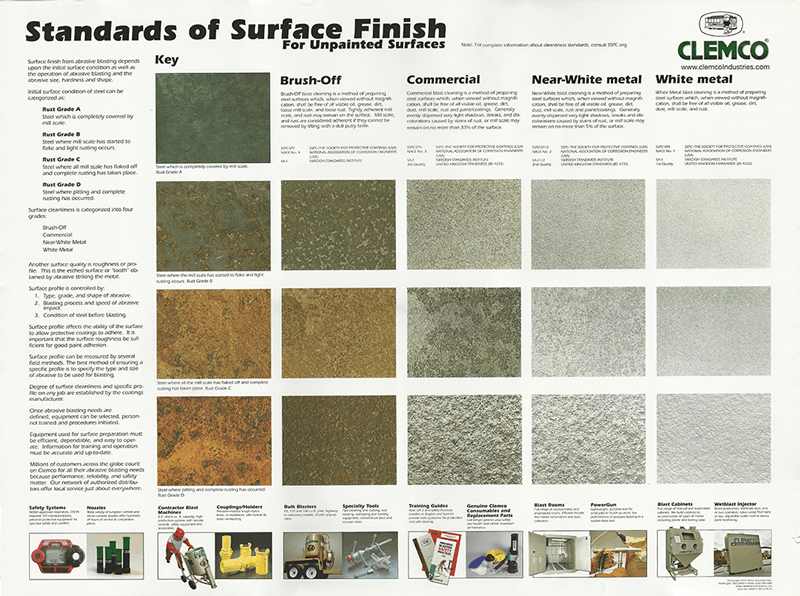

Standards of Surface Finish Chart Hodge Clemco

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Metal Surface Finish Chart

What is Surface Finish? Units, Symbols & Chart

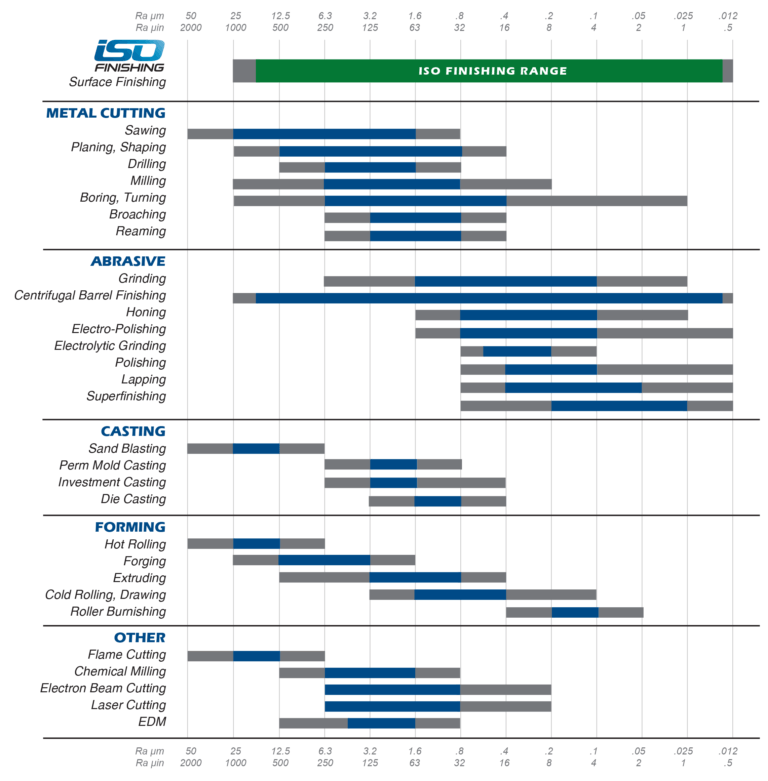

The Only Surface Finishing Chart (and Guide) You'll Ever Need

Ra Surface Roughness Chart

Steel Finish Chart A Visual Reference of Charts Chart Master

Stainless Steel Finish Chart

Surface Roughness Chart Comparison ISO Finishing

Surface Finish Is A Term Describing The Texture Of The Surface Of A Printed Object.

Web Surface Finish Refers To The Process Of Altering A Metal’s Surface That Involves Removing, Adding, Or Reshaping.

It Is Quantified By The Vertical Deviations Of A Real Surface From Its Ideal Form.

It Provides A Visual Guide To Different Surface Finishes, With Notations And Surface Roughness Values.

Related Post: