Sublimation Printable Heat Press Temperature Guide

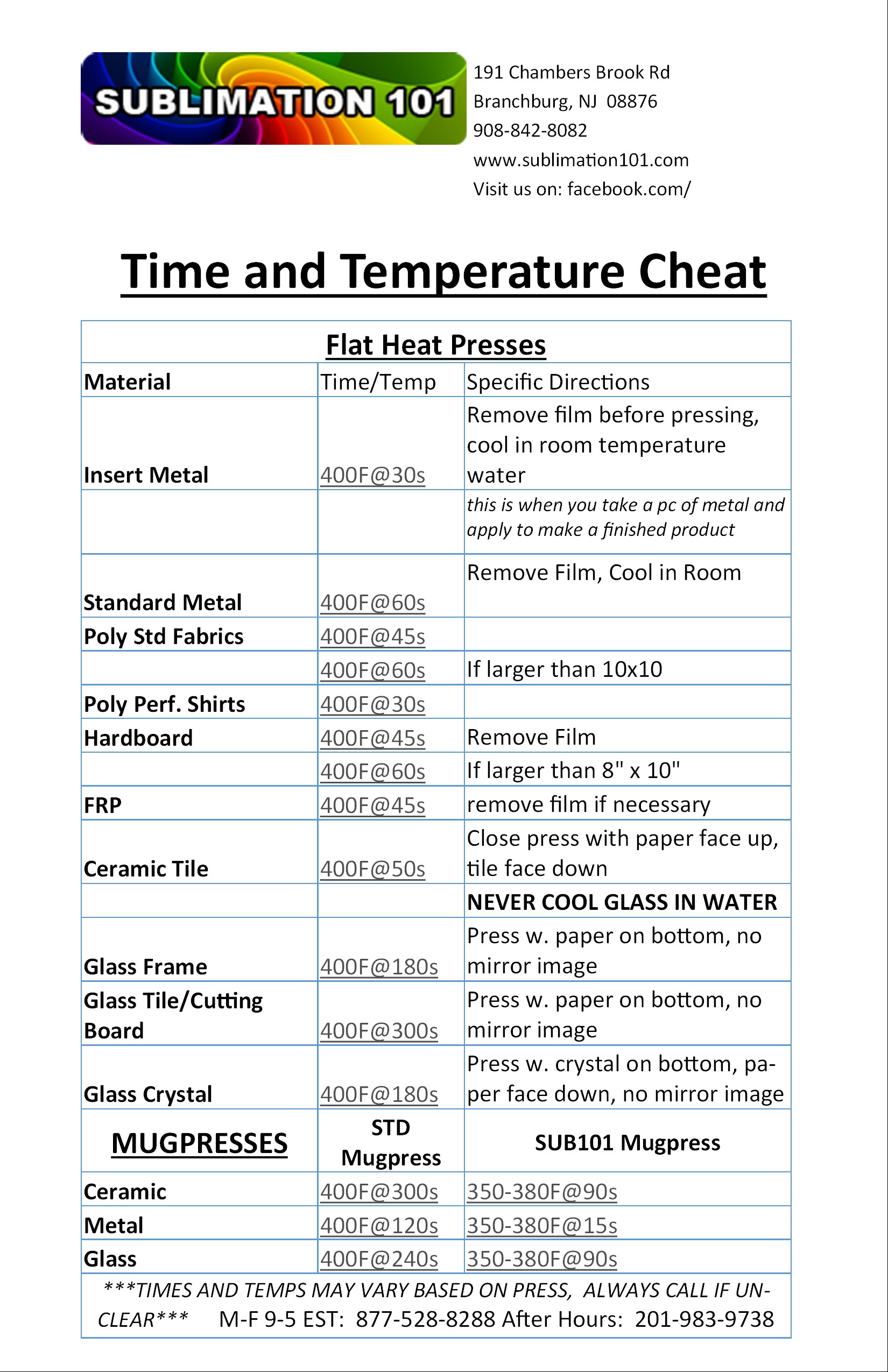

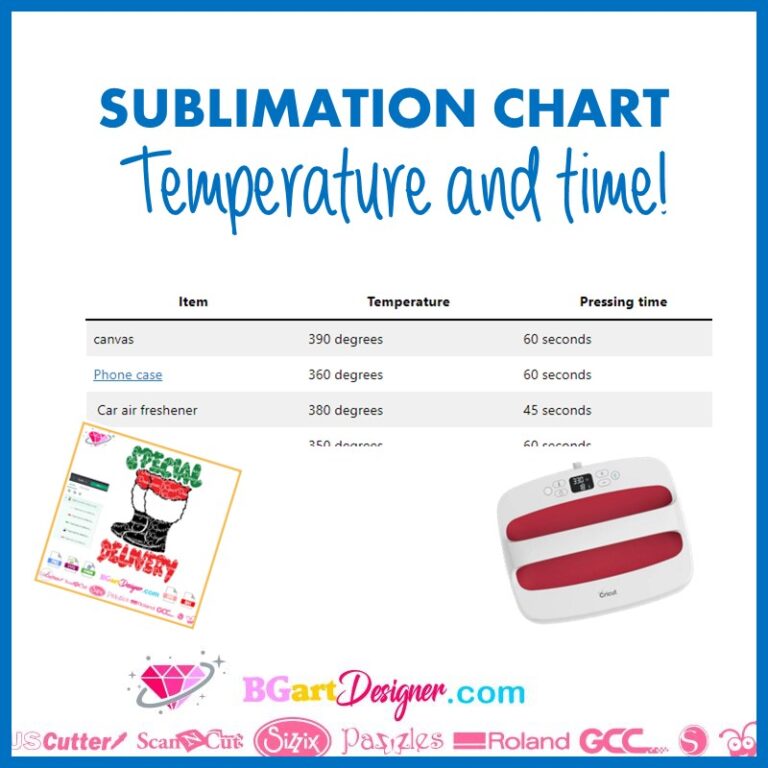

Sublimation Printable Heat Press Temperature Guide - 1 year warranty on the heat press. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and. How do i find the right sublimation heat press settings? From a mere 30 seconds on some blanks, up to five minutes or more for others! So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. This press guide provides our recommended time, temperature, and pressure settings for sublimating sawgrass inks by substrate material. Web press into silicon pad. For example, cotton requires less time than polyester. 380°f to 400°f (193°c to 204°c) time: Use my guide as a starting place and then make notes if you find the sweet spot. Cricut easypress mini chart downloads. Web press into silicon pad. From a mere 30 seconds on some blanks, up to five minutes or more for others! For heat press temperature and time settings, please refer to the recommended values of the material if available. For example, cotton requires less time than polyester. Higher temperatures can overcook your sublimation prints. First, you need to find the type of substrate you’re printing on. It demands precision in temperature. How to determine the best sublimation heat press settings? The amount of press time you’ll need to sublimation your blank varies wildly depending on your blank. Terms & conditions will be available in your orders on amazon. Web press into silicon pad. Clear materials may be either adhesive front or. Or you plan to apply the heat transfer vinyl for sublimation first on cotton, then you need to set the temperature at 266 to 284°f for htv vinyl. Whether you have a heat press, easypress, mug. The temperature range will vary with different substrates. Always warm up your heat press before printing the design. 380°f to 400°f (193°c to 204°c) time: I created different versions of the chart so you can grab whichever one you need. How to determine the best sublimation heat press settings? So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. What temperature do i put my heat press on for sublimation? It demands precision in temperature. How do i find the right sublimation heat press settings? From a mere 30 seconds on some blanks, up to five minutes or more. Transfer should be slightly larger than film and placed face down on the substrate (adhesive side down). Web simply click “user guide” for more info. For more info about sublimation printing, visit elmlib.org/sublimation. First, you need to find the type of substrate you’re printing on. Always warm up your heat press before printing the design. Higher temperatures can overcook your sublimation prints. Web press into silicon pad. Web sublimation heat press quick guide. How do i find the right sublimation heat press settings? Lifetime warranty on the heating element. You can usually find this information in the product manual or on the manufacturer’s website. Web press into silicon pad. For more info about sublimation printing, visit elmlib.org/sublimation. The following chart should serve only as a starting place. 380°f to 400°f (193°c to 204°c) time: For heat press temperature and time settings, please refer to the recommended values of the material if available. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. Use my guide as a starting place and then make notes if you find the sweet spot. 380°f to 400°f (193°c to 204°c) time:. Siser easysubli htv for all fabrics including cotton and dark polyester. These settings serve as a helpful starting point for achieving successful results. How to determine the best sublimation heat press settings? The following chart should serve only as a starting place. What temperature do i put my heat press on for sublimation? Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and practice! Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and. 30 seconds to 4 minutes, depending on the substrate. Lifetime warranty on the heating element. This chart is to use as a guide to get started. Web sublimation heat press quick guide. Web sublimation heat press settings. Then, you need to find the appropriate temperature and pressure for that substrate. You can usually find this information in the product manual or on the manufacturer’s website. This requires more than just quality designs; Web what temperature should i set my heat press to? From a mere 30 seconds on some blanks, up to five minutes or more for others! Tips for cchieving the best sublimation results. Cricut easypress chart for heat and time settings. 380°f to 400°f (193°c to 204°c) time: How to cut sublimation paper with cricut?

Sublimation Printable Heat Press Temperature Guide

Sublimation Heat Press Temperature Chart A Complete Guide

Cheat Sheet Printable Heat Press Temperature Guide

Printable Cheat Sheets for Sublimation Heat Press Temperature Settings

Printable Heat Press Temperature Guide

Heat Press Temperature Guide Sublimation and HTV Angie Holden The

Sublimation temperature and time chart

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

Printable Cheat Sheets for Sublimation Heat Press Temperature Etsy

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

The Following Chart Should Serve Only As A Starting Place.

These Settings Serve As A Helpful Starting Point For Achieving Successful Results.

Siser Easysubli Htv For All Fabrics Including Cotton And Dark Polyester.

For Example, Cotton Requires Less Time Than Polyester.

Related Post: