Sunnen Honing Stones Chart

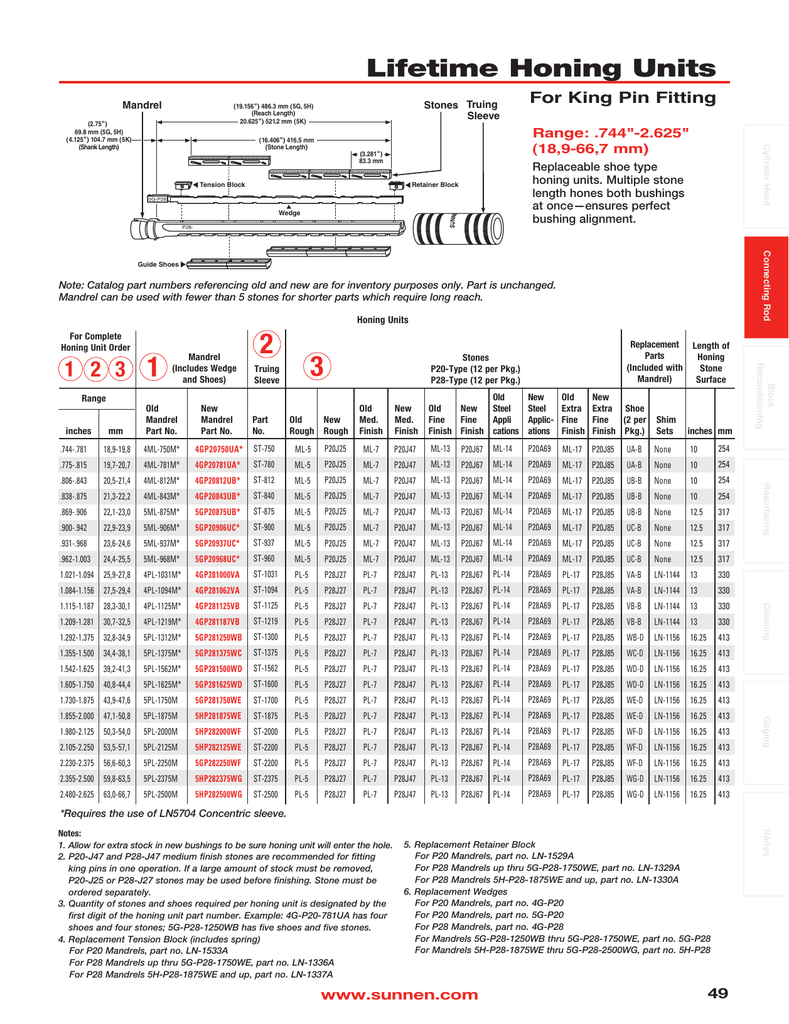

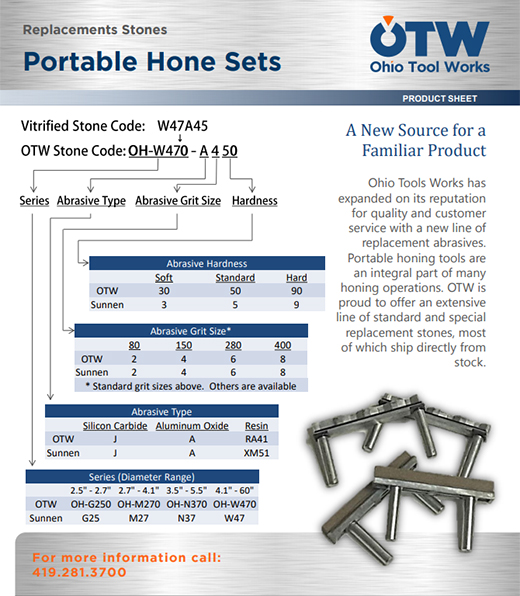

Sunnen Honing Stones Chart - #109 vertical honing fixtures above and beyond honing www.sunnen.com. Web check the sunnen honing oil and coolant selection/ information charts (back cover) to properly match the right sunnen honing oil to your specific honing requirement. Cbn 600 3″ & 3.5″. If honing units shown have stone length too long, shorten the stones as instructed on page 12.3. Web each set consists of two master stoneholders that use p28 diamond or cbn stones (select stones from the p28 superabrasive selection chart on page 2.50). Web dh diamond hone head size ranges minimum grit size order example: A honing stone is like a file in many respects. True in stone set using truing sleeve. Web these genuine sunnen 150 grit honing stones are sized for honing 2.7 to 4.1 diameter cast iron cylinders. Two stones required per set. Open the catalog to page 7. Web these genuine sunnen 150 grit honing stones are sized for honing 2.7 to 4.1 diameter cast iron cylinders. Cbn 500 3″ & 3.5″. Start honing with both pressure dials set at 0. Web each set consists of two master stoneholders that use p28 diamond or cbn stones (select stones from the p28 superabrasive. Web dh diamond hone head size ranges minimum grit size order example: Web sunnen engineers devoted extensive research into developing the highest quality honing abrasives, honing stones and honing tools specifically for bore sizing and finishing. Open the catalog to page 1. We stock a wide variety on an style honing stone sets. Web excessive stone and guide shoe wear. Web excessive stone and guide shoe wear and slow stock removal. When correction of bow or waviness is the reason for external honing, select tooling from table below. #109 vertical honing fixtures above and beyond honing www.sunnen.com. We stock a wide variety on an style honing stone sets. Web dh diamond hone head size ranges minimum grit size order example: All stone sets must be used with sunnen honing oil when honing aluminum. If honing units shown have stone length too long, shorten the stones as instructed on page 12.3. Web these genuine sunnen 150 grit honing stones are sized for honing 2.7 to 4.1 diameter cast iron cylinders. #109 vertical honing fixtures above and beyond honing www.sunnen.com. Web rottler. Open the catalog to page 7. Web sunnen® honing techniques data file: All stone sets must be used with sunnen honing oil when honing aluminum. True in stone set using truing sleeve. Web dh diamond hone head size ranges minimum grit size order example: We stock a wide variety on an style honing stone sets. All stone sets must be used with sunnen honing oil when honing aluminum. Honing tools designed to handle these bores are available from stock. Start honing with both pressure dials set at 0. Cbn 600 3″ & 3.5″. Open the catalog to page 7. Open the catalog to page 1. Web sunnen an style stone sets. Use a softer stone (one with a lower hardness number) check oil to be sure you are using sunnen industrial honing oil*. #109 vertical honing fixtures above and beyond honing www.sunnen.com. In the case of fine surface finishes, the honing oil must figure 10, stacking (loose) fig. Due to the fast cutting action and stock removal of sunnen stones when honing aluminum cylinders, the stones may not have time to become fully trued in before final size is reached. All stone sets must be used with sunnen honing oil when honing. Web sunnen an style stone sets. In the case of fine surface finishes, the honing oil must figure 10, stacking (loose) fig. As a rule, a setting of 1/4 on this scale is the maximum pressure to use with this d6 and d8 tooling(see figure2). True in stone set using truing sleeve. A honing stone is like a file in. Web excessive stone and guide shoe wear and slow stock removal. Our focus is not blurred by involvement with abrasives for other applications, such as grinding. Web dh diamond hone head size ranges minimum grit size order example: When correction of bow or waviness is the reason for external honing, select tooling from table below. Open the catalog to page. A honing stone is like a file in many respects. Use a softer stone (one with a lower hardness number) check oil to be sure you are using sunnen industrial honing oil*. Web a fine grit hone, the surface imperfections become clearly visible. Start honing with both pressure dials set at 0. Web when surface finishing or precision sizing is the reason for using the external hone, use a single stone and guide shoe in the proper hone body. Web excessive stone and guide shoe wear and slow stock removal. It pays to use genuine sunnen honing oil. In the case of fine surface finishes, the honing oil must figure 10, stacking (loose) fig. Sunnen honing techniques 2 notes. Cbn 600 3″ & 3.5″. If honing units shown have stone length too long, shorten the stones as instructed on page 12.3. As a rule, a setting of 1/4 on this scale is the maximum pressure to use with this d6 and d8 tooling(see figure2). Each set includes 2 stones and 2 wipers. Web sunnen engineers devoted extensive research into developing the highest quality honing abrasives, honing stones and honing tools specifically for bore sizing and finishing. Due to the fast cutting action and stock removal of sunnen stones when honing aluminum cylinders, the stones may not have time to become fully trued in before final size is reached. #109 vertical honing fixtures above and beyond honing www.sunnen.com.

sunnen honing stone grit chart Bamil

China Sunnen Honing Stones Chart Manufacturer and Supplier, Factory

sunnen honing stone grit chart Bamil

China Factory supplied Sunnen Honing Stones Chart Honing mandrel

sunnen honing stone grit chart Bamil

Honing Guide Wall Chart

Abrasives Other Abrasives L12J67 SUNNEN LH13 BOX OF 6 HONING STONES

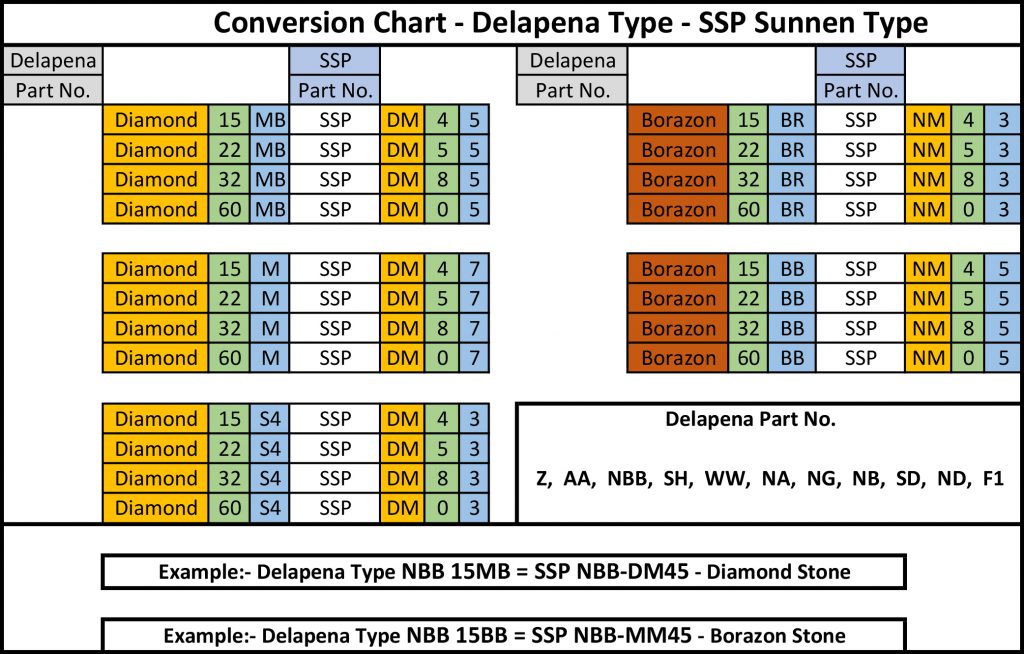

Honing Stone Delapena Type SSP Technology

sunnen honing stone grit chart Bamil

China Factory supplied Sunnen Honing Stones Chart Honing mandrel

All Stone Sets Must Be Used With Sunnen Honing Oil When Honing Aluminum.

Now Any Degree Of Fine Finish Can Be Achieved With A Finer Grit Honing Stone And With Only A Very Few

Our Focus Is Not Blurred By Involvement With Abrasives For Other Applications, Such As Grinding.

When Correction Of Bow Or Waviness Is The Reason For External Honing, Select Tooling From Table Below.

Related Post: