Teflon Gasket Torque Chart

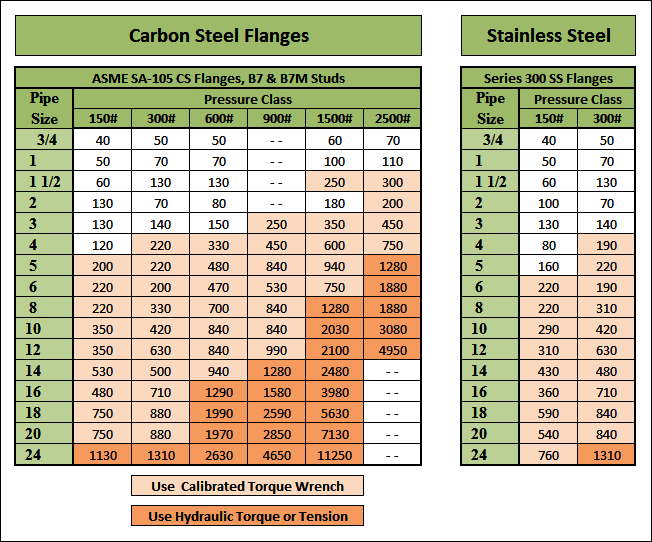

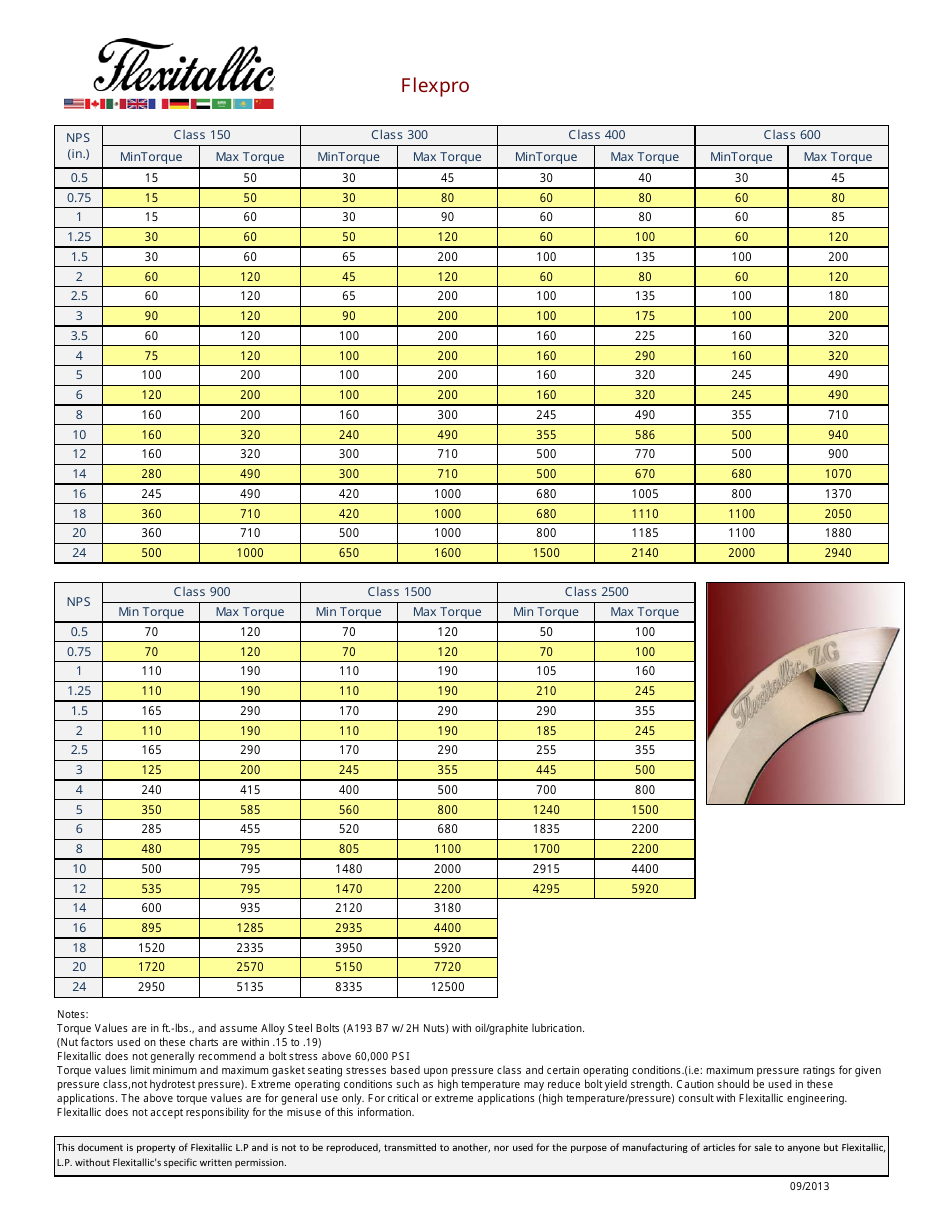

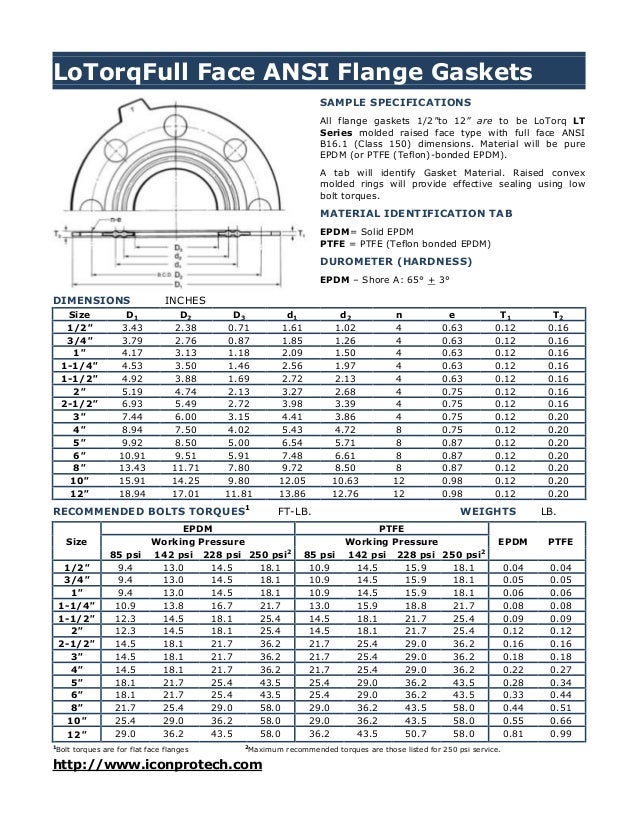

Teflon Gasket Torque Chart - Bolt materials listed are per asme a193. Nps (in.) min torque max torque min torque max torque min torque. Web this chart gives the torque value for the final pass. Ptfe gasket manufacturer in india, we specialize in offering ptfe teflon gaskets,. After hand tightening, torquing must follow a cross bolting sequence as exampled in annex 12.1 of teadit’s “industrial. Qty (metric) (unc) 1″ 25. Web all torque values in the chart above are based on using the tensile area of the fastener. Target residual stresses apply to standard pipe flanges that are fabricated in accordance with asme b16.5. (nut factors used on these. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Target residual stresses apply to standard pipe flanges that are fabricated in accordance with asme b16.5. Flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Ring gasket on raised face steel flange dn (mm) pn 6 pn 10 pn 16 pn 25 pn 40. Web gore. The pressure rating of the material may vary depending on the grade. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: (nut factors used on these. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and. Recommended bolt torques for ptfe lined piping. (nut factors used on these. Nps (in.) min torque max torque min torque max torque min torque. Ptfe gasket manufacturer in india, we specialize in offering ptfe teflon gaskets,. Web all torque values in the chart above are based on using the tensile area of the fastener. Target residual stresses apply to standard pipe flanges that are fabricated in accordance. The pressure rating of the material may vary depending on the grade. Web minimum torque recommended per bolt = (2,500 psi) (4,844 psi) x (120 ft.lbs.) minimum torque recommended per bolt = 62 ft.lbs. (nut factors used on these. Web this chart gives the torque value for the final pass. Flexitallic is the market leader in the manufacture and supply. Target residual stresses apply to standard pipe flanges that are fabricated in accordance with asme b16.5. The pressure rating of the material may vary depending on the grade. Bolt materials listed are per asme a193. Swg (type 913 and 913m). Class 150 class 300 class 400 class 600. Bolt materials listed are per asme a193. Web change gasket torque chart. Web recommended torque value chart. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. After hand tightening, torquing must follow a cross bolting sequence as exampled in annex 12.1 of teadit’s “industrial. Bolt materials listed are per asme a193. Gasket calculator (excel spreadsheet) this excel (xlxs) file provides helpful references for raised face flange torque, gasket stress, bolt tables, and. The pressure rating of the material may vary depending on the grade. After hand tightening, torquing must follow a cross bolting sequence as exampled in annex 12.1 of teadit’s “industrial. Web torque. Bolt materials listed are per asme a193. After hand tightening, torquing must follow a cross bolting sequence as exampled in annex 12.1 of teadit’s “industrial. The pressure rating of the material may vary depending on the grade. Recommended bolt torques for ptfe lined piping flange studs; This torque table applies for 1/16 and 1/8 thick homogeneous elastomeric gaskets. Ring gasket on raised face steel flange dn (mm) pn 6 pn 10 pn 16 pn 25 pn 40. Web gore ® universal pipe gasket (style 800) • gore gr sheet gasketing bolt torque: Bolt materials listed are per asme a193. Spiral wound gaskets suggested torque values (ft/lbs) for style wr & wri to asme b16.20 suggested torque value. Flexitallic. Ring gasket on raised face steel flange dn (mm) pn 6 pn 10 pn 16 pn 25 pn 40. Qty (metric) (unc) 1″ 25. Web this chart gives the torque value for the final pass. (nut factors used on these. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: This torque table applies for 1/16 and 1/8 thick homogeneous elastomeric gaskets. The pressure rating of the material may vary depending on the grade. Class 150 class 300 class 400 class 600. Ptfe gasket manufacturer in india, we specialize in offering ptfe teflon gaskets,. Target residual stresses apply to standard pipe flanges that are fabricated in accordance with asme b16.5. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Web change gasket torque chart. Web recommended torque value chart. Flexitallic is the market leader in the manufacture and supply of static sealing solutions, delivering high quality industrial gaskets on a global scale. Web gore ® universal pipe gasket (style 800) • gore gr sheet gasketing bolt torque: After hand tightening, torquing must follow a cross bolting sequence as exampled in annex 12.1 of teadit’s “industrial. Web all torque values in the chart above are based on using the tensile area of the fastener. Ring gasket on raised face steel flange dn (mm) pn 6 pn 10 pn 16 pn 25 pn 40. Spiral wound gaskets suggested torque values (ft/lbs) for style wr & wri to asme b16.20 suggested torque value. (nut factors used on these. Web ptfe is physiologically inactive and may be utilized in direct contact with food.

Flexpro Gasket Torque Chart Flexitallic spiral wound gasketflexital

Torque Chart Spiral Wound Gaskets vlr.eng.br

Teflon Gasket Torque Chart

Teflon Coated Bolt Torque Chart

Flexitallic Cgi Gasket Torque Chart Home Interior Design

Epdm Gasket Torque Chart A Visual Reference of Charts Chart Master

Teflon Coated Bolt Torque Chart

Teflon Gasket Torque Chart

Epdm Gasket Torque Chart

Flange Isolation Gasket Kits StepKo Products

Web Chemical Resistance Charts For Metallics And Fluoropolymers;

The Pressure Rating Of The Material May Vary Depending On The Grade.

Web Minimum Torque Recommended Per Bolt = (2,500 Psi) (4,844 Psi) X (120 Ft.lbs.) Minimum Torque Recommended Per Bolt = 62 Ft.lbs.

(Nut Factors Used On These.

Related Post: