Tig Tungsten Size Chart

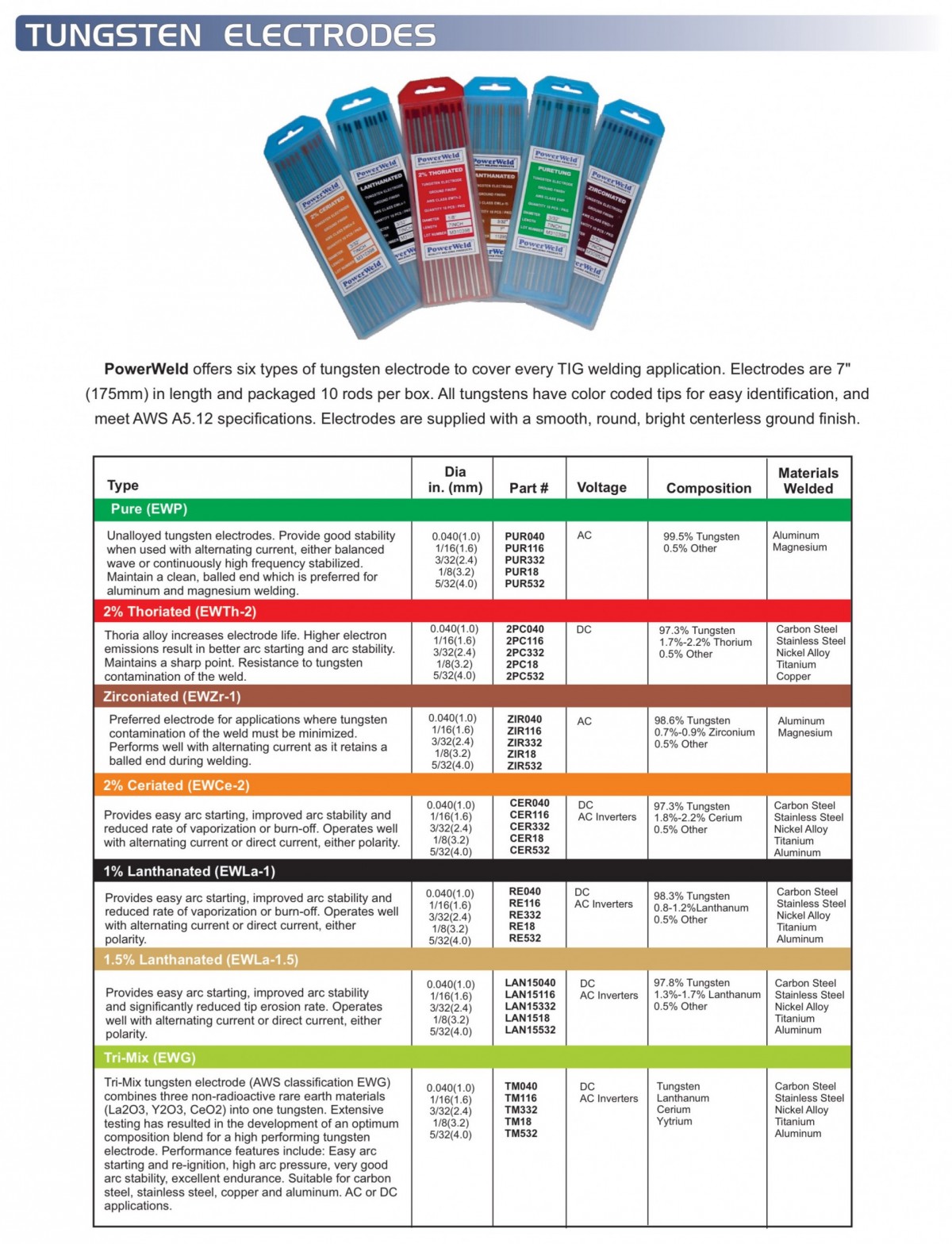

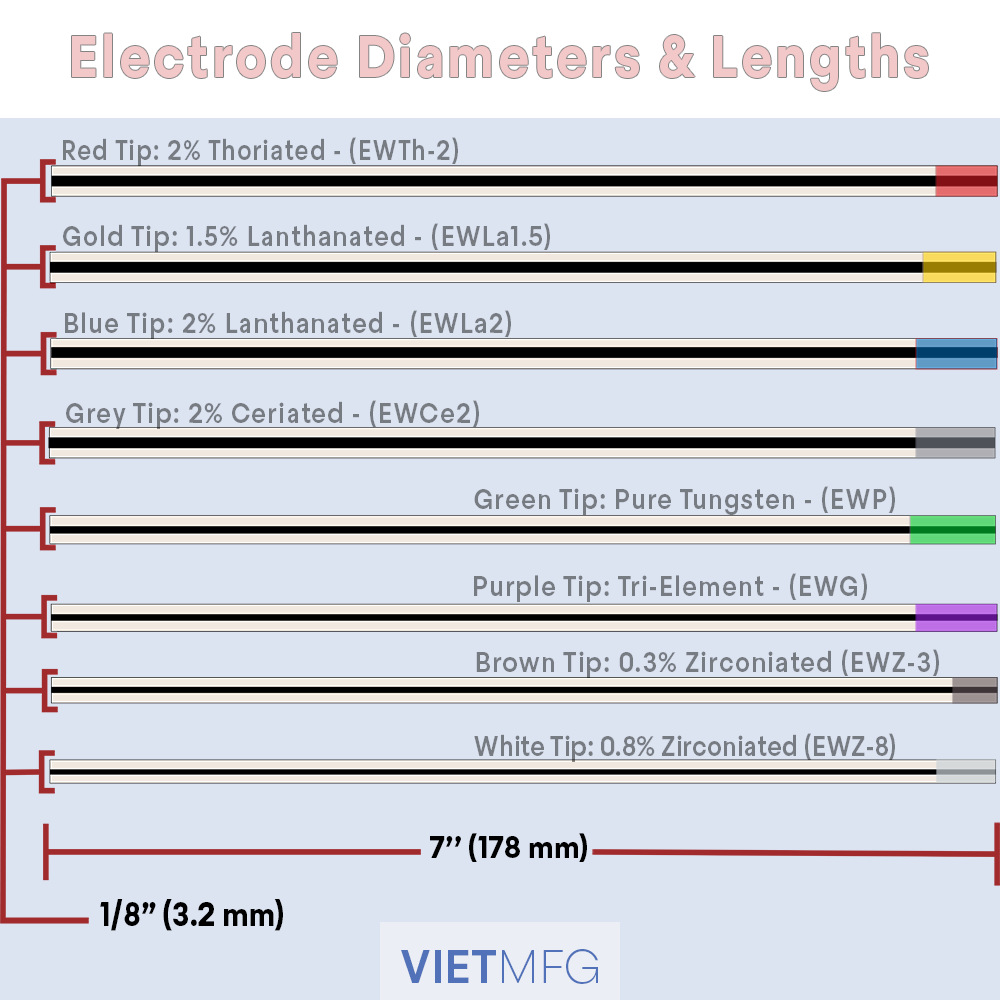

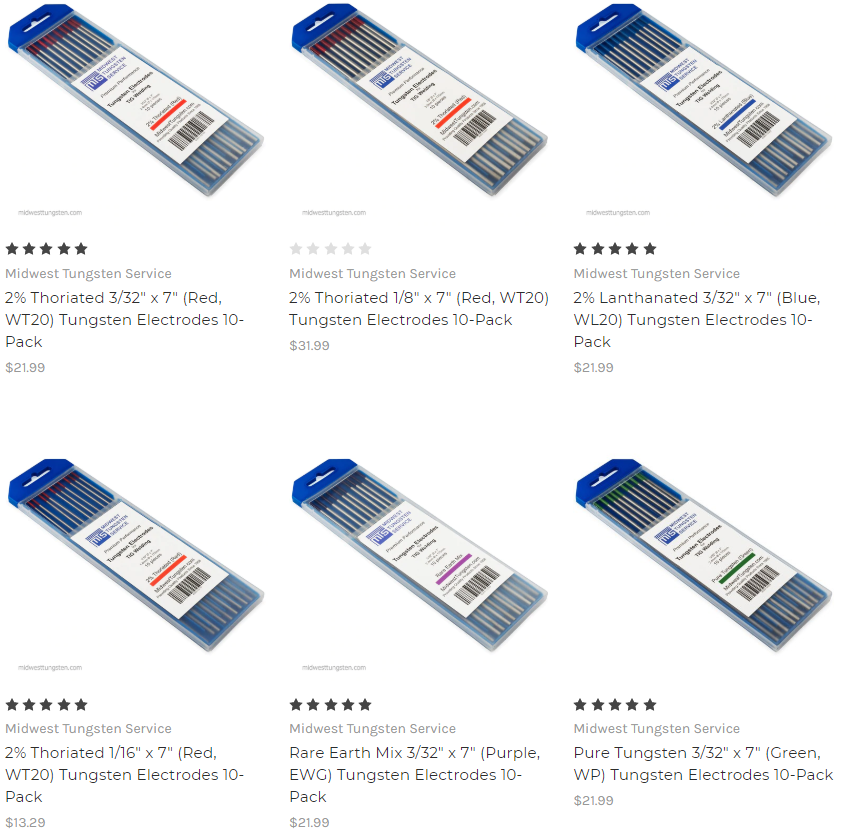

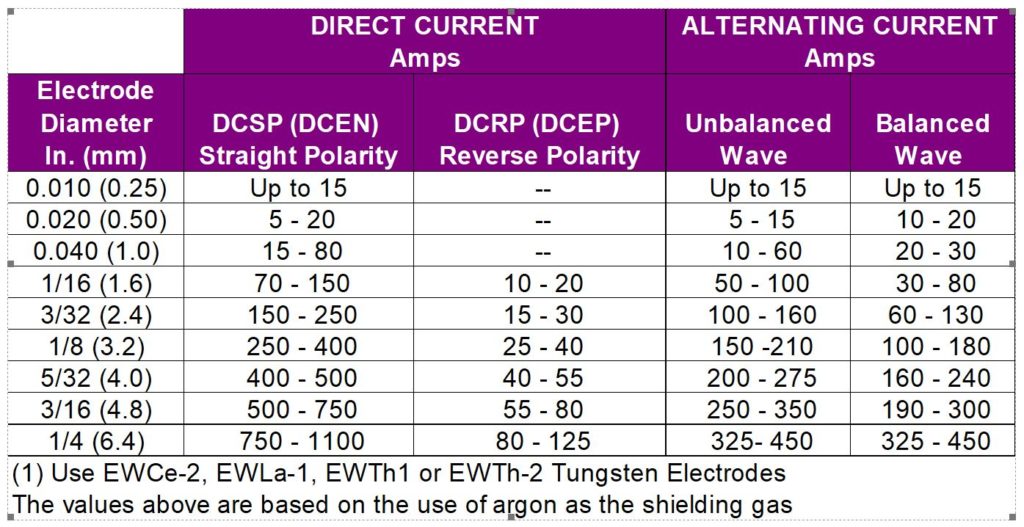

Tig Tungsten Size Chart - Easy arc starts, and long life. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. The positive characteristic of tungsten makes it a foundation of tungsten inert gas (tig) welding. Web get the most out of your welds by picking the right tig welding tungsten. The table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. Compare the benefits and drawbacks of different tungsten types, such as thoriated, lanthanated,. In addition to these sizes, some manufacturers also offer.020” (0.5mm) and ¼” (6.4. Web learn how to choose the right tungsten electrode for your tig welding needs based on the australian standard colours and properties. It caters to different material types and thicknesses for effective welding. Easy arc starts, high current carrying capacity, similar to thoriated. To help you choose, we’ve provided some tips below. The table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. The positive characteristic of tungsten makes it a foundation of tungsten inert gas (tig) welding. Take a look at our chart to know what tungsten you need to use. Selecting the right tungsten. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web choosing the right tungsten for your tig weld can be a daunting task. Web learn about the different types and sizes of tungsten electrodes for tig welding, such as thoriated, lanthanated, and zirconated. Click the chart to get the full size. Web gtaw, or. For this reason, electrode selection should be an important part of the welding equipment setup process. Web different types and sizes of tig welding tungsten electrodes in our product family. The best size and type of electrode depends on your preference and your application. Web the size of the tungsten electrode must, thus, be based on the choice of tungsten. We break down the different tungsten colors and explain when you should use each one. Web mechanized tig welding mechanized tig welding encompasses a wide spectrum of applications such as precision bellows welding using.040 diameter tungsten electrode at 1.0 ampere up to high speed tube mills welding with a.250 diameter tungsten electrode using current as high as 600 amperes. To. The best size and type of electrode depends on your preference and your application. Web an improper tungsten size or cup size can also cause tungsten discoloration. Larger diameters sustain higher amperages and last longer, while smaller diameters allow for ease of starting the arc. Web tungsten is a rare metallic element with the highest melting point of any metal,. Web tungsten is a rare metallic element with the highest melting point of any metal, 3,410 degrees celsius. 1/16 x 7 1.6 x 175mm: Take a look at our chart to know what tungsten you need to use. Easy arc starts, high current carrying capacity, similar to thoriated. The positive characteristic of tungsten makes it a foundation of tungsten inert. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. In addition to these sizes, some manufacturers also offer.020” (0.5mm) and ¼” (6.4. This article does not provide a tungsten size chart for tig welding. Compare the benefits and drawbacks of different tungsten types, such as thoriated, lanthanated,. Larger diameters sustain higher amperages and last. Be sure to match your tungsten size and cup size to the joint being welded. To help you choose, we’ve provided some tips below. Web get the most out of your welds by picking the right tig welding tungsten. For this reason, electrode selection should be an important part of the welding equipment setup process. Tungsten diameter and cup size. Web get the most out of your welds by picking the right tig welding tungsten. Tungsten diameter and cup size. Web learn how to choose the right tungsten electrode for your tig welding needs based on the australian standard colours and properties. See the chart below for current ranges of all sizes. We need a lot less flow in tig. Web tungsten is a rare metallic element with the highest melting point of any metal, 3,410 degrees celsius. The table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web the size of the tungsten electrode must, thus,. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). Web learn about the different types of tungsten electrodes for tig welding, how to choose the right diameter and color code, and how to sharpen and store them. Tungsten diameter (mm) material thickness (mm) amperage (amps) 1.6. We break down the different tungsten colors and explain when you should use each one. In addition to these sizes, some manufacturers also offer.020” (0.5mm) and ¼” (6.4. 2% thoriated.020 x 7 0.5 x 175mm: Take a look at our chart to know what tungsten you need to use. Web tungsten is a rare metallic element with the highest melting point of any metal, 3,410 degrees celsius. Web tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding and plasma arc welding (paw). Web learn how to choose the right tungsten electrode for your tig welding needs based on the australian standard colours and properties. Each stick of tungsten has a color code applied to 3/32 x 7 2.4 x 175mm:. The table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. Web gtaw, or tig, welding uses a tungsten electrode to form an arc with the workpiece using an inert gas, generally argon or helium.

Tig Tungsten Chart Labb by AG

Choose The Perfect Tungsten TIG Welding With Canaweld

Tig Welding Tungsten Chart

TIG Tungsten Electrodes Explained (with Color Chart)

![Tips For Selecting Tungsten Electrodes [TIG Welding]](https://weldingpros.net/wp-content/uploads/2020/04/tungsten-electrodes.jpg)

Tips For Selecting Tungsten Electrodes [TIG Welding]

Tig Welding Tungsten Color Chart Best Picture Of Chart

TIG Welding Tungsten Electrode Selection Chart Midwest Tungsten Service

Tig Weld Amp Chart

TIG Tungsten Electrode Types Jasic Blog

Tig Tungsten Size Chart

We Need A Lot Less Flow In Tig Welding.

Good Arc Stability For Ac.

The Current Polarity, Power Source, Thickness Of The Material, And Metal Type Play A Role In Tungsten Selection.

Selecting The Right Tungsten Electrode Is An Essential Part Of Tig Welding.

Related Post: