Tig Weld Chart

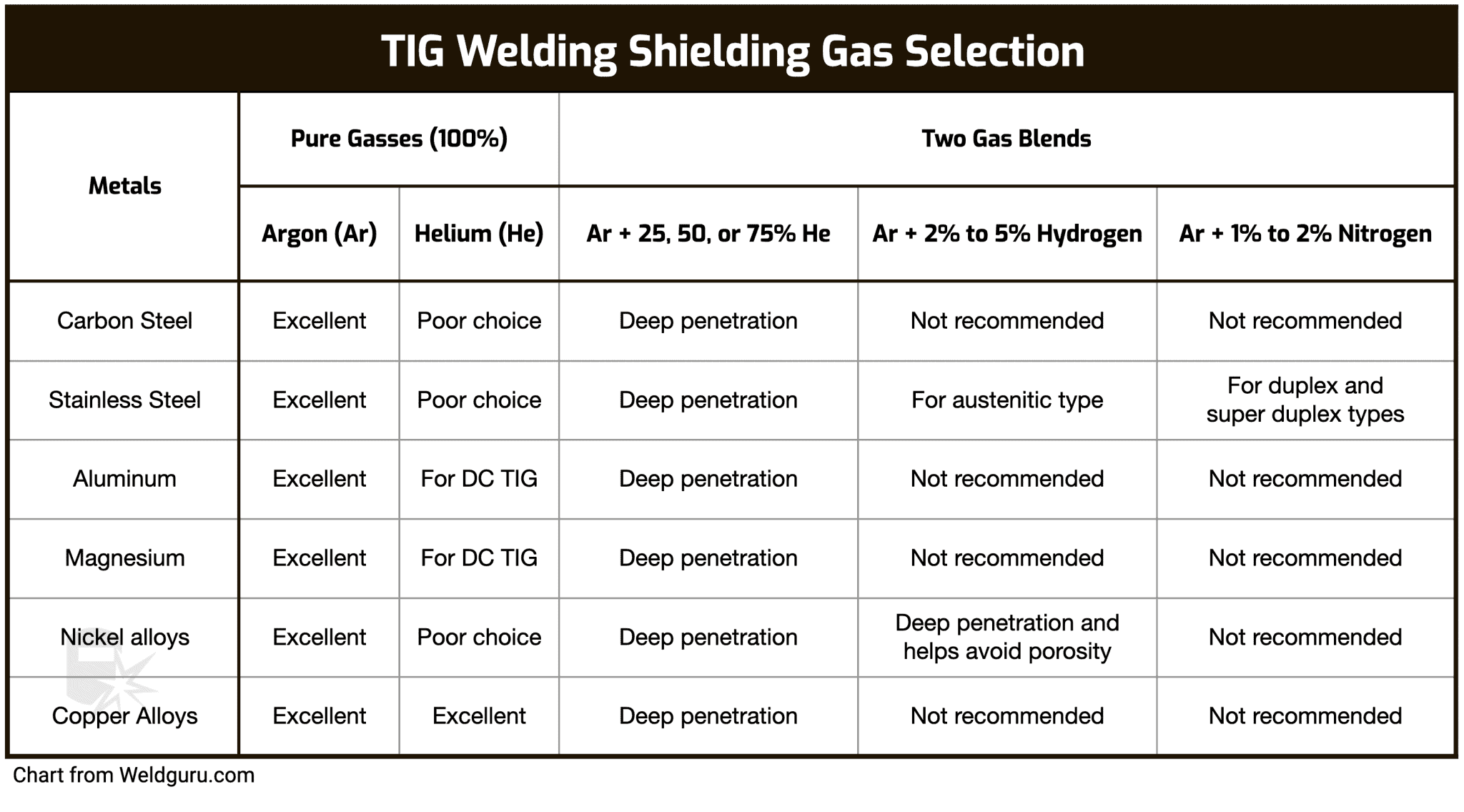

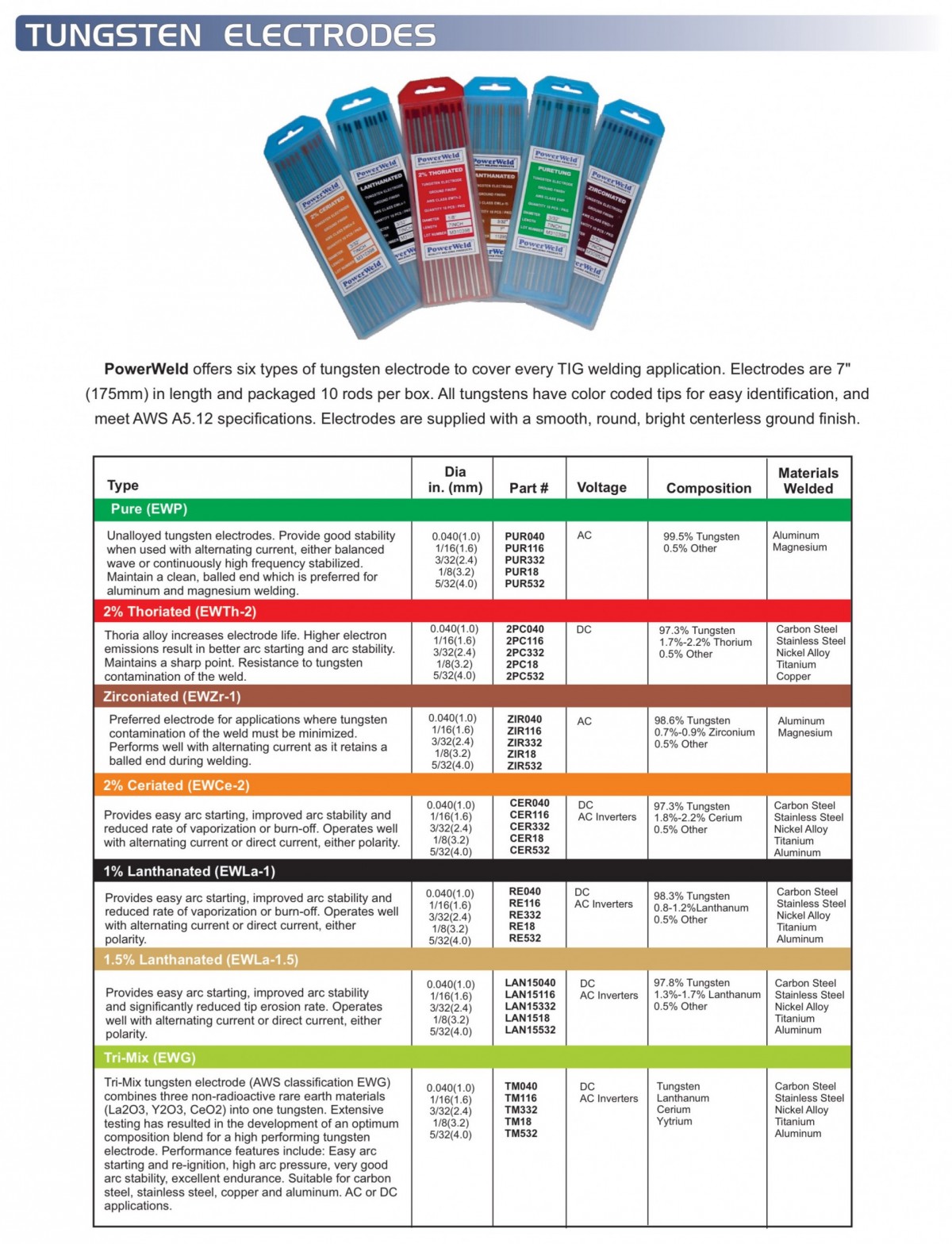

Tig Weld Chart - The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Web tig welding tungsten electrode selection chart. Web tig welding chart based on material and shielding gas. For mild steel, it recommends running 10% lower amps for complete beginners. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. If you’re new to tig welding, the process of selecting the correct settings can be overwhelming. Filler metal can be either wire or rod and should be compatible with the base alloy. Print this selection chart and keep it in your work area as a useful reference when selecting the tungsten material for your next project. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Filler metal can be either wire or rod and should be. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Free online tig welding training. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work. It caters to different material types and thicknesses for effective welding. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web tig welding tungsten electrode selection chart. Once you get the hang of tig welding you might find you prefer to weld at higher or. Once you get the hang of tig welding you might find you prefer to weld at higher or lower amps depending on technique and travel speed. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. For mild steel, it recommends running 10% lower amps for complete beginners. Web see the chart below for. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Nearly sixty years of experience have gone into producing these premium quality tig welding tungsten electrodes, and you benefit from that experience. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Print this selection chart and keep it in. Knowing which filler rod to use during the welding process is an important part of achieving successful welds. Web tig welding tungsten electrode selection chart. It caters to different material types and thicknesses for effective welding. Print this selection chart and keep it in your work area as a useful reference when selecting the tungsten material for your next project.. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. For mild steel, it recommends running 10% lower amps for complete beginners. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct current (“dc”) and argon or. The three main types of metals typically worked. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Use ac (alternating current) when welding aluminum and magnesium. Web tig welding filler rod chart. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. And even two dissimilar metals. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Tig welding can be. Web improve your tig welding with tig tips and tricks and weld calculators, or learn to tig weld with training materials and mobile apps. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Web see the chart below for recommended flow rates. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Web empower your tig welding projects with our free online tig welding calculator. Browse suggested weld parameter settings for tig welding. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Ck worldwide offers an introduction to tig torches, how they are made, and how to select the right torch for the job. Tungsten electrode current ranges 8. Tig welding is a complex and precise process that requires the right tools and techniques to be used correctly. Nearly sixty years of experience have gone into producing these premium quality tig welding tungsten electrodes, and you benefit from that experience. For mild steel, it recommends running 10% lower amps for complete beginners. It caters to different material types and thicknesses for effective welding. Web tig welding tungsten electrode selection chart. Web the color chart below summarizes the various tig tungsten electrodes you may come across: Knowing which filler rod to use during the welding process is an important part of achieving successful welds.

Tig Welding Rods Chart

TIG Welding Charts ILMO Products Company

TIG Tungsten Electrodes Explained (with Color Chart)

The 25+ best Tig welding process ideas on Pinterest Mig welding

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials

Aluminum Tig Welding Settings Chart

Tig Welding Settings Chart Pdf

What Gas Should You Use for TIG Welding? (with Chart)

Tig Welding Tungsten Chart

TIG Welding Charts ILMO Products Company

Filler Metal Can Be Either Wire Or Rod And Should Be Compatible With The Base Alloy.

Web Tig Welding Is A Precise And Intricate Welding Technique That Requires An Understanding Of The Different Tig Welder Settings.

Web A Tig Welding Chart Visually Represents The Welding Parameters Needed To Achieve A Specific Weld.

It Notes That The Chart Provides Starting Point Amps That May Need Adjusting Based On Technique And Travel Speed.

Related Post: