Tig Welding Amps To Metal Thickness Chart

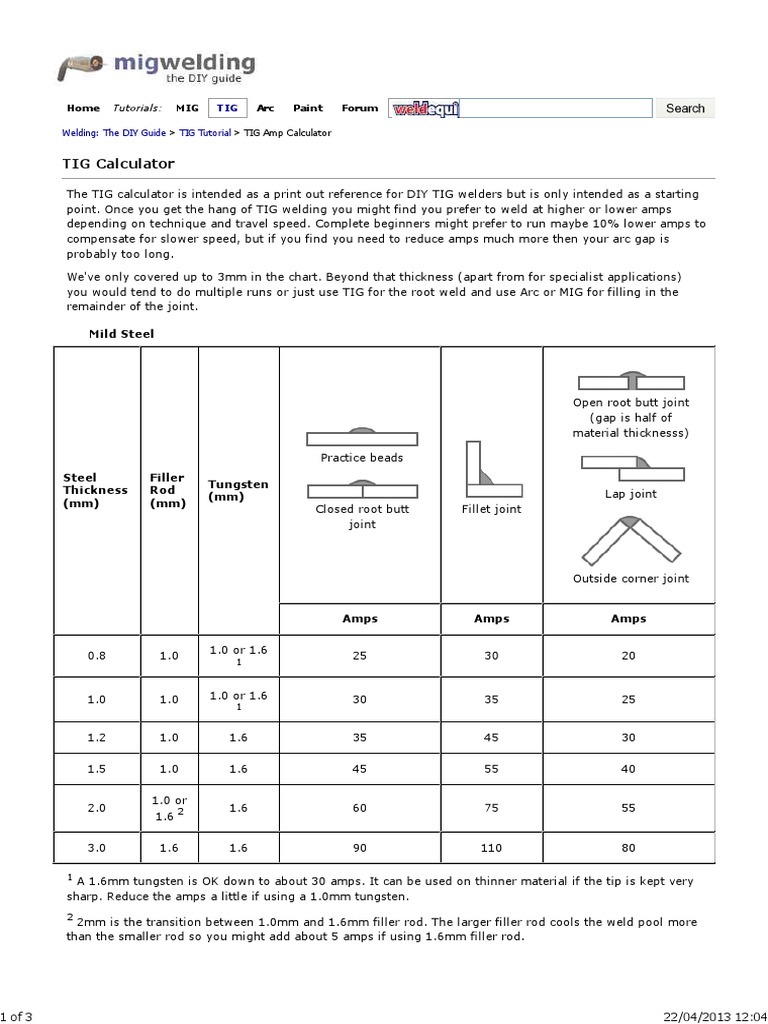

Tig Welding Amps To Metal Thickness Chart - So, how many amps does it take to weld 3/8 steel? Web printable charts shiowing the amps and tungstons you might select for various thiknesses, joint types and materials. Web mild and low carbon steels with less then 0.30% carbon and less than 1 (2.5cm) thick, generally do not require preheat. An exception to this allowance is welding on highly restrained joints. These joints should be preheated 50 to 100°f (10 to 38°c) to minimize shrinkage cracks in the base metal. For beginners it’s recommended to stick with a 3/32” diameter tungsten. The welding processes which we will explore in the context of amperage selection are these three main processes: Web welding low alloy steel. It caters to different material types and thicknesses for effective welding. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. An exception to this allowance is welding on highly restrained joints. Web when tig welding different thickness parts, say for example in a lap joint of a piece of 3/16 flat bar to a.14 ga (.080)square tube (mild steel or ss parts) (. We’ve put together a reference based on recommendations from the american welding society. Web welding low alloy steel. It lists recommended amperages for different weld joint types and thicknesses. Tig (gas tungsten arc welding, or gtaw), mig (gas metal arc welding, or gmaw), and stick (shielded metal arc welding, or smaw). Web mild and low carbon steels with less than. However, as the thickness increases, tig welding falls slightly behind due to slower deposition rates and the high skill cap required. We’ve put together a reference based on recommendations from the american welding society. Web printable charts shiowing the amps and tungstons you might select for various thiknesses, joint types and materials. The three main types of metals typically worked. So, how many amps does it take to weld 3/8 steel? Web mild and low carbon steels with less than 0.30% carbon and less than 1 (2.5cm) thick, generally do not require preheat. However, as the thickness increases, tig welding falls slightly behind due to slower deposition rates and the high skill cap required. Stainless steel and aluminium amps chart.. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Tig (gas tungsten arc welding, or gtaw), mig (gas metal arc welding, or gmaw), and stick (shielded metal arc welding, or smaw). It caters to different material types and thicknesses for effective welding. Web regarding metal types and different thicknesses, tig. These joints should be preheated 50 to 100°f (10 to 38°c) to minimize shrinkage cracks in the base metal. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Web amperage chart for different metals and their thickness. It lists recommended amperages for different weld joint types and thicknesses. An exception. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Web welding process and amperage selection. Web regarding metal types and different thicknesses, tig welding is one of the best. For beginners it’s recommended to stick with a 3/32” diameter tungsten. Web mild and low carbon steels with less then 0.30% carbon and less than 1 (2.5cm) thick, generally do not require preheat. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Thicker materials will require. I'm in the process of making a welding table and i've burned a few holes on the 1 1/2 0.95 square iron i'm using for the frame of the table. So, how many amps does it take to weld 3/8 steel? For mild steel, it recommends running 10% lower amps for complete beginners. Web amperage chart for different metals and. The welding processes which we will explore in the context of amperage selection are these three main processes: It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. These joints should be preheated 50 to 100°f (10 to 38°c) to minimize shrinkage cracks in the base metal. Thicker materials will require. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. The charts are intended as a starting point for beginner and intermediate tig welders. Web printable charts shiowing the amps and tungstons you might select for various thiknesses, joint types and materials. Web mainly on the material thickness and the amperage needed to achieve a proper weld. Web when tig welding different thickness parts, say for example in a lap joint of a piece of 3/16 flat bar to a.14 ga (.080)square tube (mild steel or ss parts) ( other would be a joint of small tube dia to solid rod like the one in the tig finger video), what would be the guideline for setup, amperage, tungsten dia, rod dia, and most important how. Web although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. However, as the thickness increases, tig welding falls slightly behind due to slower deposition rates and the high skill cap required. We’ve put together a reference based on recommendations from the american welding society. Web amperage chart for different metals and their thickness. These joints should be preheated 50 to 100°f (10 to 38°c) to minimize shrinkage cracks in the base metal. I'm in the process of making a welding table and i've burned a few holes on the 1 1/2 0.95 square iron i'm using for the frame of the table. Web welding low alloy steel. An exception to this allowance is welding on highly restrained joints. Web sheet metal is defined as a metal that is less than 0.06 inches or 1.5 millimeters in thickness and can include aluminum, stainless steel, and mild steel. Thicker materials will require more current and thus bigger tungsten.

Tig Welding Rods Chart

Tig Welding Amps To Metal Thickness Chart

Tig Welding Amperage Chart

Welding Amps Metal Thickness Chart

TIG Welding Charts ILMO Products Company

Welding Amps To Metal Thickness Chart

TIG Welding Charts ILMO Products Company

Tig parameters chart MIG Welding Forum

TIG Welding Amp Charts Welding Building Materials

Aluminum Tig Welding Settings Chart

Web The Calculator Below Pinpoints Exactly Which Electrode You Need For The Metal You Are Welding.

Web The Amperage Required When Tig Welding Is Highly Affected By The Type Of Metal You Are Working With And How Thick That Metal Is.

These Joints Should Be Preheated 50 To 100°F (10 To 38°C) To Minimize Shrinkage Cracks In The Base Metal.

Additionally, You Might Have Your Own Preference That Fits Your Unique Situation.

Related Post: