Tig Welding Cup Size Chart

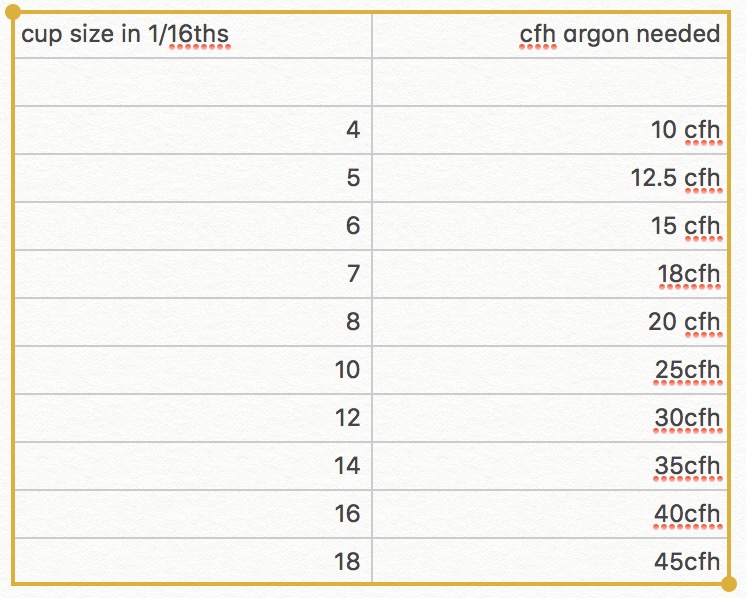

Tig Welding Cup Size Chart - Browse suggested weld parameter settings for tig welding. (800) 426.0877 when tig welding, there are three choices of welding current. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization (achf). Web tig torch cup size. Filler metal can be either wire or rod and should be compatible with the base alloy. Web the cup is a ceramic attachment that goes on the end of the tig torch that directs the argon gas onto the weld. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Po box 1636 auburn, wa 98071 usa. Web this document outlines factors to consider when selecting proper cup size for tig welding and how to measure a cup size. Web so here is a quick chart using 2.5 as a factor for setting argon flow per cup size. Web cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). Web so here is a quick chart using 2.5 as a factor for setting argon flow per cup size. (800) 426.0877 when tig welding, there are three choices of welding current. Choosing the correct size depends on material thickness, joint type,. Web as a referent point i used 35 cfh (the maximum) for 12 cup, and i assumed that the flow of 35cfh will achieve the best laminar flow (in reality it will not, lower cfh will give better results, but i wanted to use the maximum). See the chart below for current ranges of all sizes. Web gas tungsten arc. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization (achf). 9, 20, 24 tig torch consumables tungsten electrodes tig welding electrodes usually contain small quantities of metallic oxides, which can offer the following benefi ts: Web this document outlines factors to consider when selecting proper cup size for tig welding. Web the table below is the recommended tig tungsten size for welding material of a wide range of thicknesses. Can i cut back on the gas with a smaller cup? Web weld quality while reducing downtime and costs. See the chart below for current ranges of all sizes. The type of current used will have a great effect on the. Filler metal can be either wire or rod and should be compatible with the base alloy. We need a lot less flow in tig welding. We need a lot less flow in tig welding. Web gas tungsten arc welding (gtaw) or tig (tungsten inert gas) welding is an arc welding process that uses a tungsten electrode to produce an electric. It is possible to guide the shielding gas directly onto the welding zone by making use of a cup or cup. These gtaw torch parts are common across most types of gtaw welding machines, with the differences being in how these elements are adapted to different roles. There also are different sizes for different types of torches, such as a. Web for beginners, it’s recommended to stick with a 3/32” diameter tungsten. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. There are a variety of torches within the different weldcraft series. The tig process can be used to weld everything from. We need a lot less flow in tig welding. Can i cut back on the gas with a smaller cup? Web technical specifications for tig welding. Web weld quality while reducing downtime and costs. A smaller cup (e.g., 6mm to 10mm) is generally sufficient for welding thinner materials. Web tig torch cup size. The size you choose depends on various factors, including the welding application, the thickness of the material, and the type of gas used. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. I started with a #7 as it came with the torch. Adequate gas flow for gmaw typically. We need a lot less flow in tig welding. I started with a #7 as it came with the torch. Web this document outlines factors to consider when selecting proper cup size for tig welding and how to measure a cup size. (concord, nc) how do you determine the best cup size. The size you choose depends on various factors,. Web weld quality while reducing downtime and costs. Po box 1636 auburn, wa 98071 usa. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web as a referent point i used 35 cfh (the maximum) for 12 cup, and i assumed that the flow of 35cfh will achieve the best laminar flow (in reality it will not, lower cfh will give better results, but i wanted to use the maximum). Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. I started with a #7 as it came with the torch. We need a lot less flow in tig welding. See the chart below for current ranges of all sizes. We need a lot less flow in tig welding. Web technical specifications for tig welding. For tig welding, common choices include #4 (1/4″), #5 (5/16″), #6 (3/8″), #7 (1/16″) and #8 (1/2″). Web for beginners, it’s recommended to stick with a 3/32” diameter tungsten. Web cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). Web tig torch cup size. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Can i cut back on the gas with a smaller cup?

Tig Cup Size Chart

A Better TIG Experience Hot Rod Network

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25 with Gas Le

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25/17/18/26 wi

Tig Cup Size Chart

Tig Welding Cup Size Chart Best Picture Of Chart

Tig Welding Settings Chart

How To Determine Cup Size For Tig Welding

![How Do I Choose a TIG Welding Cup Size? [Chart] Beginner Welding Guide](https://m.media-amazon.com/images/I/41RlflLp+tL._SL500_.jpg)

How Do I Choose a TIG Welding Cup Size? [Chart] Beginner Welding Guide

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25 with Gas Le

Each Of These Has Its Applications, Advantages,.

These Gtaw Torch Parts Are Common Across Most Types Of Gtaw Welding Machines, With The Differences Being In How These Elements Are Adapted To Different Roles.

2.5 Cfh Per Cup Size Is Just A Rule Of Thumb But Has Seemed To Be Spot On Most Of The Time In My Experience.

Web The Cup Is A Ceramic Attachment That Goes On The End Of The Tig Torch That Directs The Argon Gas Onto The Weld.

Related Post: