Tig Wire Chart

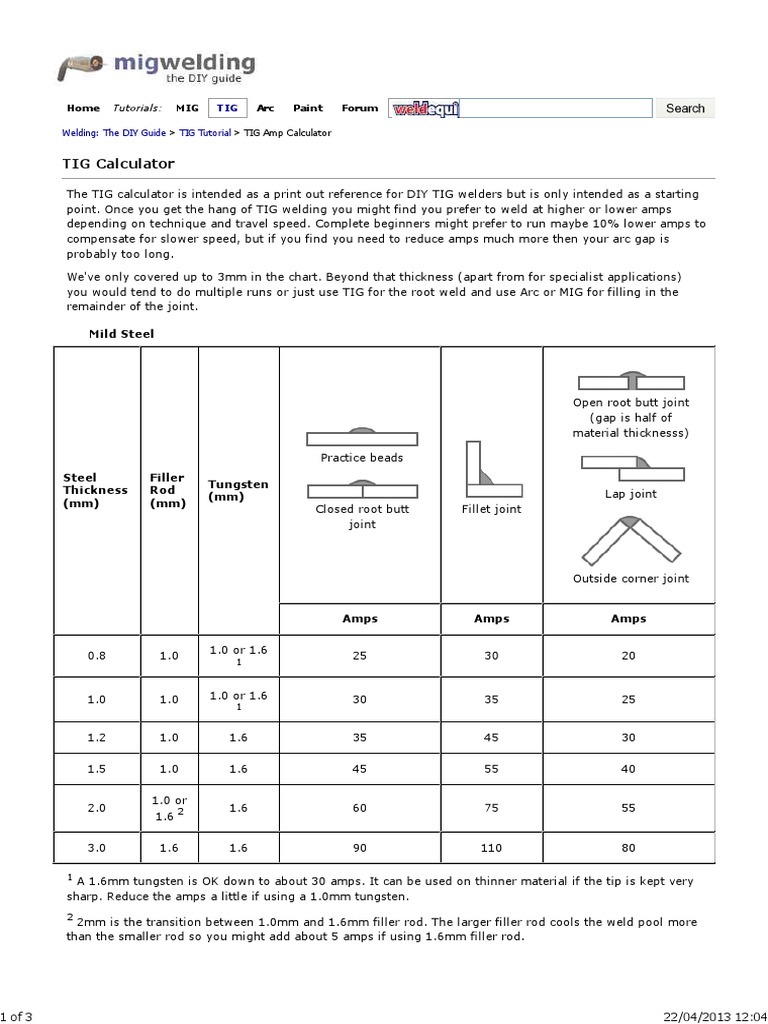

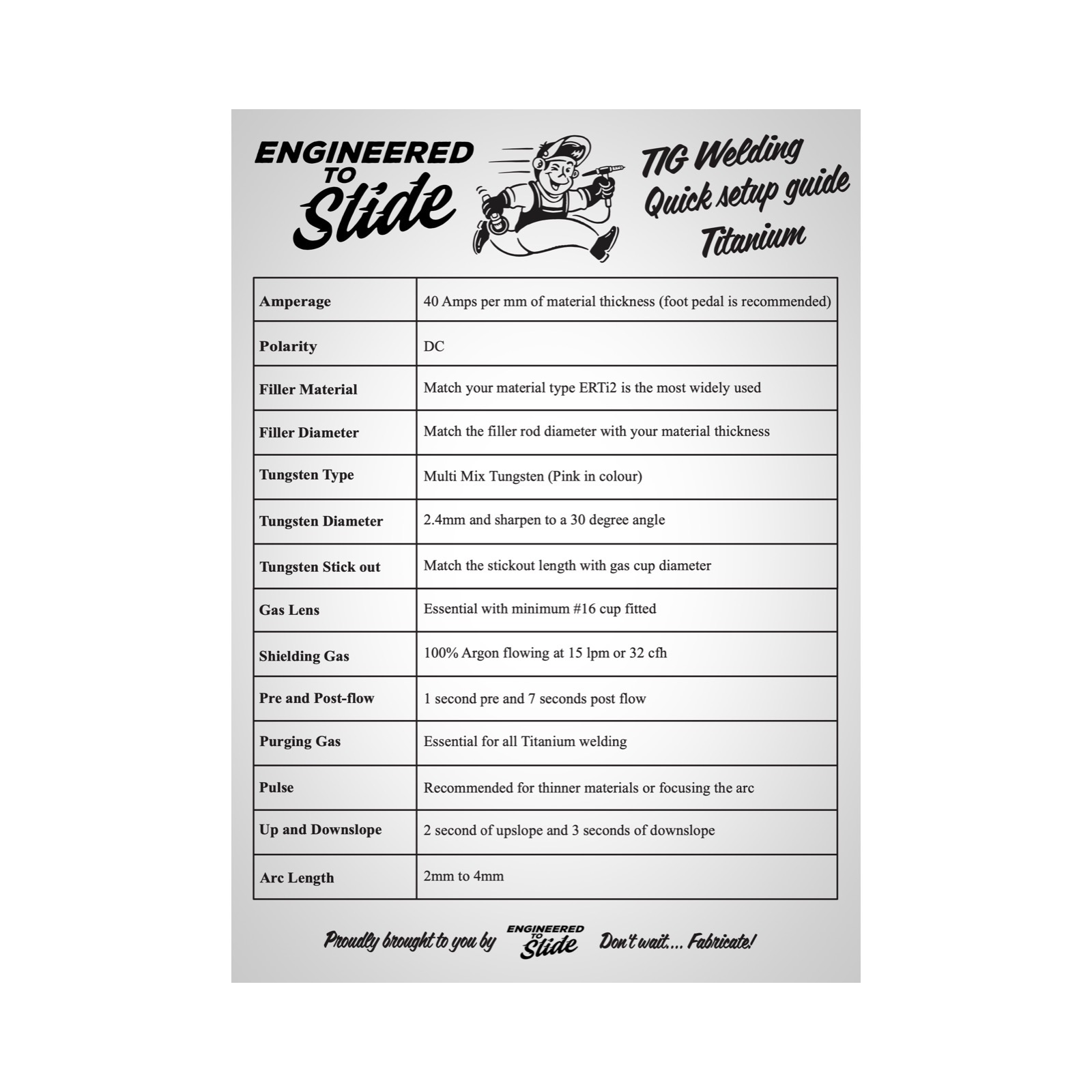

Tig Wire Chart - Web tig weld setting calculator. Back to table of contents www.ckworldwide.com when tig welding, there are three. Web tubular and solid stainless steel wires; Browse suggested weld parameter settings for tig welding. Tig filler rods for high strength steel. Web what is tig welding? For smaw process, weaving shall be 3 times core dia. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Web tig welding, short for “tungsten inert gas welding”, is a process known for creating precise, clean welds on various materials. Web what is a tig welding chart. Web in tig welding specifications for tig welding www.ckworldwide.com phone: Web typically, the mig wire process is recognized as having very low hydrogen in the deposit. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. Tig filler rods for high strength steel. Web tig welding, short for. Web tig welding amp charts. Web mig wires and tig rods filler metals made from the highest quality steel to maximize consistency, feedability and arc performance. Cup chart standard collet &. Web typically, the mig wire process is recognized as having very low hydrogen in the deposit. Web tig welding allows the welder more control. Scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld. Web this article provides an overview of tig welding filler rod chart pdf (you can download it free), which can help users find the right type of rod for their particular job needs. The tig. The american welding society (“aws”) classifies tig wires just as mig solid wire. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. The chart usually includes the current. They both fall under the “ a5.18 carbon. The tig calculator is intended as a print out reference for diy tig welders but. Filler metal suggested for wrought stainless. The american welding society (“aws”) classifies tig wires just as mig solid wire. Web 3 types of tig. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Web mig wires and tig rods filler metals made from the highest quality steel to maximize consistency,. Web 3 types of tig. What metal are you welding? Web this article provides an overview of tig welding filler rod chart pdf (you can download it free), which can help users find the right type of rod for their particular job needs. They both fall under the “ a5.18 carbon. The below chart gives very detailed guidelines for stick. Web welding electrode selection chart for carbon steel to stainless steel, all stainless steel. Back to table of contents www.ckworldwide.com when tig welding, there are three. Web filler rod classification and composition. Web the standard in tig welding 4 toll free: They both fall under the “ a5.18 carbon. Filler metal suggested for wrought stainless. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. It's especially useful for critical welding jobs in. Learn from ron covell about the different tungsten electrodes available for a variety of welding applications. The american welding society (“aws”) classifies tig wires. Web typically, the mig wire process is recognized as having very low hydrogen in the deposit. Tig filler rods for high strength steel. Web tig welding allows the welder more control. Web our full comprehensive tig welding guide will give you all the information you need about this welding process. Tig stands for tungsten inert gas and is also known. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Web mig wires and tig rods filler metals made from the highest quality steel to maximize consistency, feedability and arc performance. Web tig welding, short for “tungsten inert gas welding”, is a process known for creating precise, clean welds on various. The chart usually includes the current. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Tig filler rods for aluminium. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web what is tig welding? Web in tig welding specifications for tig welding www.ckworldwide.com phone: Web our full comprehensive tig welding guide will give you all the information you need about this welding process. The american welding society (“aws”) classifies tig wires just as mig solid wire. For smaw process, weaving shall be 3 times core dia. Welding wire thickness chart material thickness 24 gauge (.025) 22 gauge (.031) 20 gauge (.037) 18 gauge (.050) 16 gauge (.063) 14 gauge (.078) 1/8. Web tig weld setting calculator. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. Filler metal suggested for wrought stainless. Web this article provides an overview of tig welding filler rod chart pdf (you can download it free), which can help users find the right type of rod for their particular job needs. Web tubular and solid stainless steel wires; A tig welding chart visually represents the welding parameters needed to achieve a specific weld.

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Search Result Details Welding rods, Welding tips, Welding videos

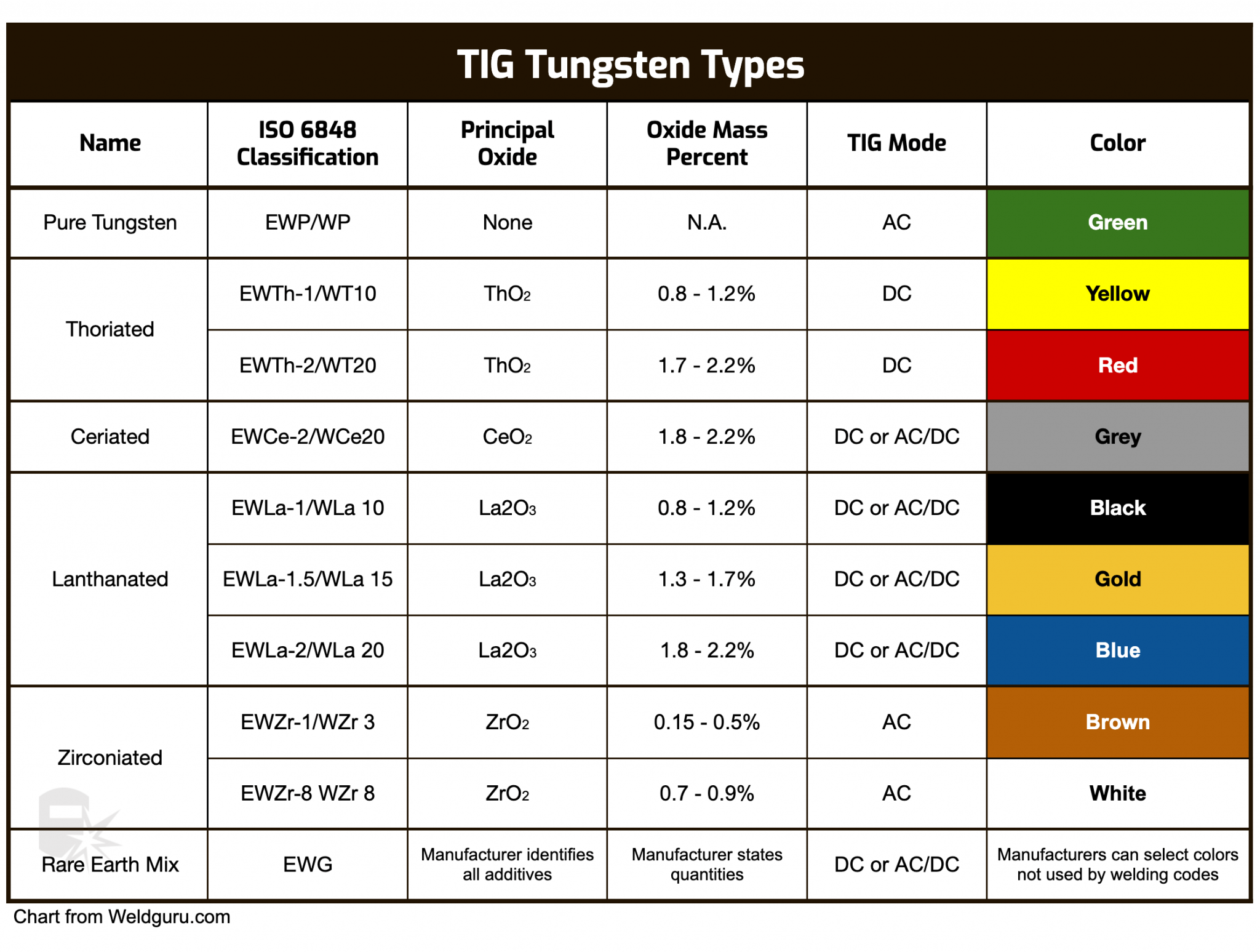

The different types of electrodes used in orbital TIG welding

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Welding Charts Engineered to Slide

TIG Welding Amp Charts Welding Building Materials

Aluminum Tig Welding Settings Chart

tig parts breakdown chart Welding Supply

TIG Welding Charts ILMO Products Company

TIG Welding Charts ILMO Products Company

Back To Table Of Contents Www.ckworldwide.com When Tig Welding, There Are Three.

Web Typically, The Mig Wire Process Is Recognized As Having Very Low Hydrogen In The Deposit.

It's Especially Useful For Critical Welding Jobs In.

Scratch Start Is The Most Basic Form Of Tig Welding And Requires Dragging The Electrode Across The Surface Of A Workpiece To Initiate The Weld.

Related Post: