Torque Chart For Ss Bolts

Torque Chart For Ss Bolts - Web bolt size tpi proof load (lbs) 1 clamp load (lbs) 2; Diameter are based on 30 ksi yield strength. Tightening torque (ft lbs) galv+waxed galv plain; (lbs.) clamp load (lbs.) = 0.15. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Web torquing specification inch & metric fastener chart. Web values given represent the torque required to induce a tension in the bolt corresponding to approximately 65% of its proof load. Web stainless steel galling see pencom technical bulletin “galling of stainless steel fasteners”. At 75% of the material proof strength. Web dry clamp load based on 40% of yield to avoid galling the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Diameter are based on 30 ksi yield strength. Web the objective of this project is to define torque values for bolts and screws when loading is not a concern. Web maximum recommended tightening torque for coarse threaded metric steel bolts: Web torquing specification inch & metric fastener chart. Web values given represent the torque required to induce a tension in. Web dry clamp load based on 40% of yield to avoid galling the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web compleate information about torque. Using the correct installation torque is critical for achieving a properly fastened joint with. Web dry clamp load based on 40% of yield to avoid galling the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near. At 75% of the material proof strength. Values calculated using industry accepted formula t. (lbs.) clamp load (lbs.) = 0.15. * this table is recommended for use as a guide. Web stainless steel galling see pencom technical bulletin “galling of stainless steel fasteners”. K = 0.15 k = 0.17 k = 0.20. At 75% of the material proof strength. Web torque values for bolts greater than 1.1/2 in. Using the correct installation torque is critical for achieving a properly fastened joint with. * this table is recommended for use as a guide. K = 0.15 k = 0.17 k = 0.20. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near. Web compleate information about torque values stainless steel bolt table chart | stud bolt torque chart | stainless steel stud bolt torque chart, torque values a2 or a4 metric. Web torquing specification inch & metric fastener chart. Tightening torque (ft lbs) galv+waxed galv plain; Web bolt size tpi proof load (lbs) 1 clamp load (lbs) 2; Web the objective of. Recommended bolt torque values for stainless steel and nonferrous fasteners (inch series). The charts below show the ideal tightening torque for each bolt grade for a variety of. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web dry clamp load based on 40% of yield to avoid galling. The charts below show the ideal tightening torque for each bolt grade for a variety of. Web torquing specification inch & metric fastener chart. Tension 85% of proof load. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near. Web the torque values can only be achieved if nut (or tapped hole). Web dry clamp load based on 40% of yield to avoid galling the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near. Web torque values for bolts greater than. Values calculated using industry accepted formula t = kdp where t = torque, k = torque coefficient. The charts below show the ideal tightening torque for each bolt grade for a variety of. The following torque values are suggested maximums based upon actual lab testing on clean and dry or near. Web 32 rows torque values stainless steel bolt table chart. Web stainless steel galling see pencom technical bulletin “galling of stainless steel fasteners”. Tension 85% of proof load. Web tightening torque (nm) property class min. Web values given represent the torque required to induce a tension in the bolt corresponding to approximately 65% of its proof load. Web compleate information about torque values stainless steel bolt table chart | stud bolt torque chart | stainless steel stud bolt torque chart, torque values a2 or a4 metric. K = 0.15 k = 0.17 k = 0.20. 4 2.6 2.3 23.0 20.7 5 5.1 4.6 45.1 40.6 6 8.7 7.8 77.0 69.3. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Diameter are based on 30 ksi yield strength. Web dry clamp load based on 40% of yield to avoid galling the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's. Web the objective of this project is to define torque values for bolts and screws when loading is not a concern. Recommended bolt torque values for stainless steel and nonferrous fasteners (inch series).

A270 Stainless Steel Hex Head Bolt A2 70 Bolt Torque & Size Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Printable Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Bolt Torque Chart

stainless steel stud bolt torque chart Torque Values Stainless Steel

Stainless Steel 316 Bolts and A4 S31600 Stud/ Hex Bolt/ Nuts/ Fasteners

Torque Charts Industrial Bolting And Torque Tools vlr.eng.br

Standard Bolt Torque Chart

Web The Torque Values Can Only Be Achieved If Nut (Or Tapped Hole) Has A Proof Load Greater Than Or Equal To The Bolt's Minimum Ultimate Tensile Strength.

* This Table Is Recommended For Use As A Guide.

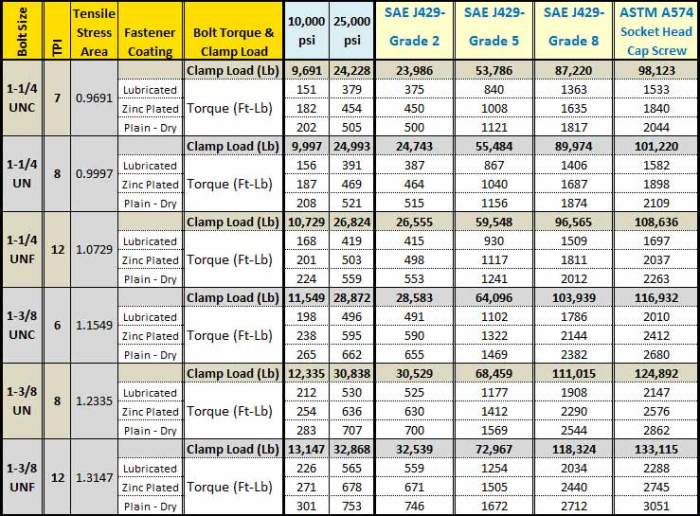

Web Bolt Size Tpi Proof Load (Lbs) 1 Clamp Load (Lbs) 2;

Tightening Torque (Ft Lbs) Galv+Waxed Galv Plain;

Related Post: