Torque Flange Chart

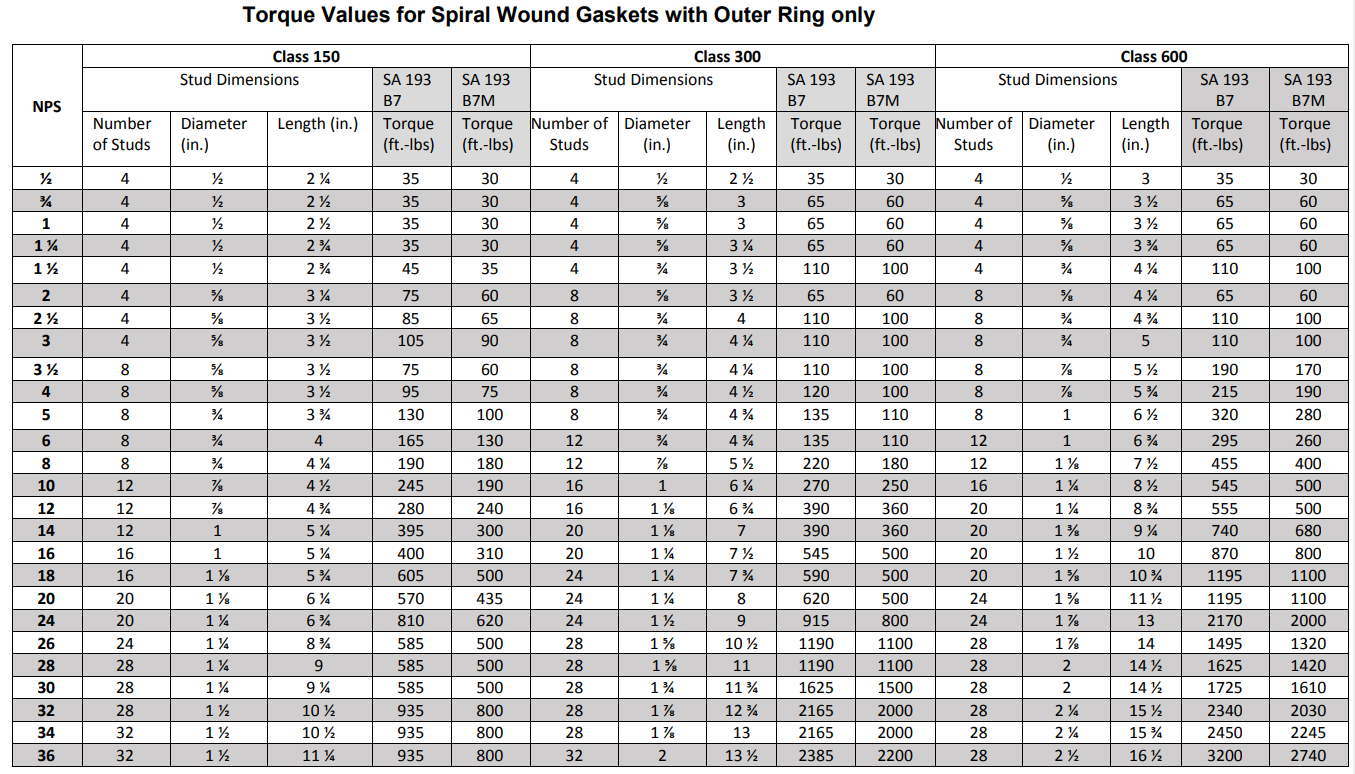

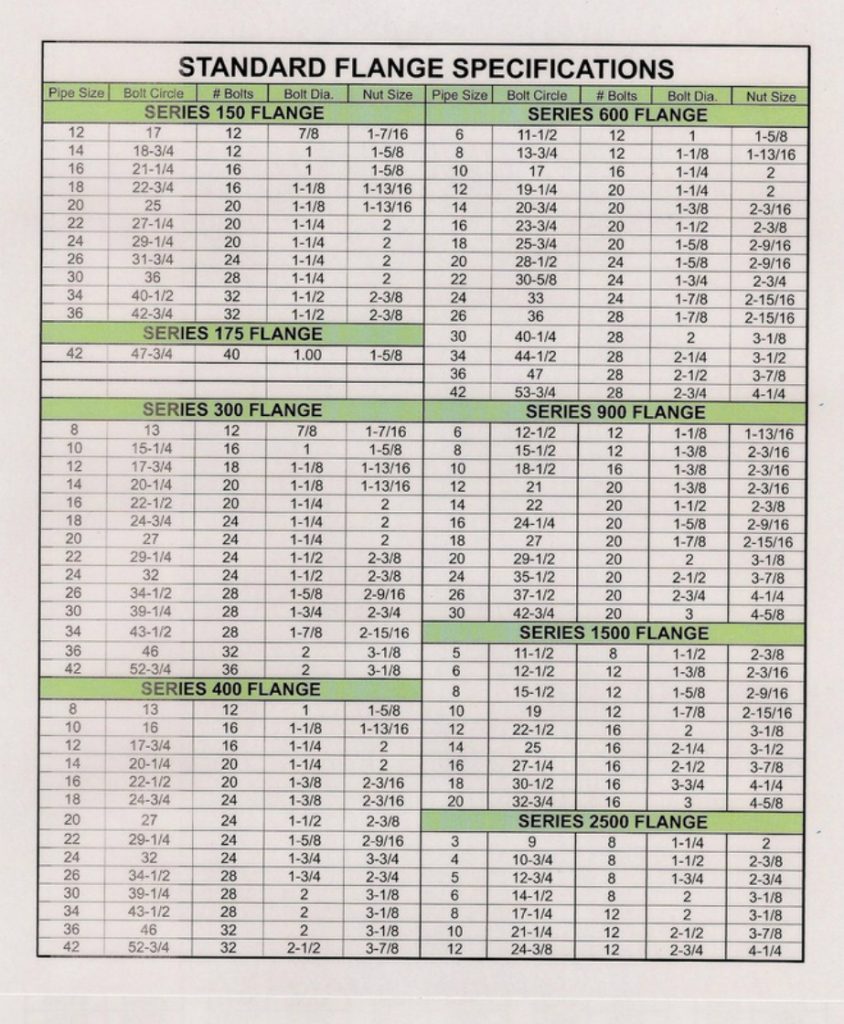

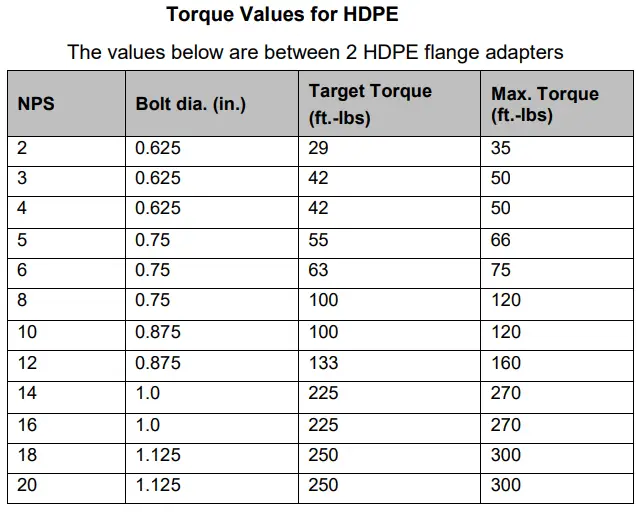

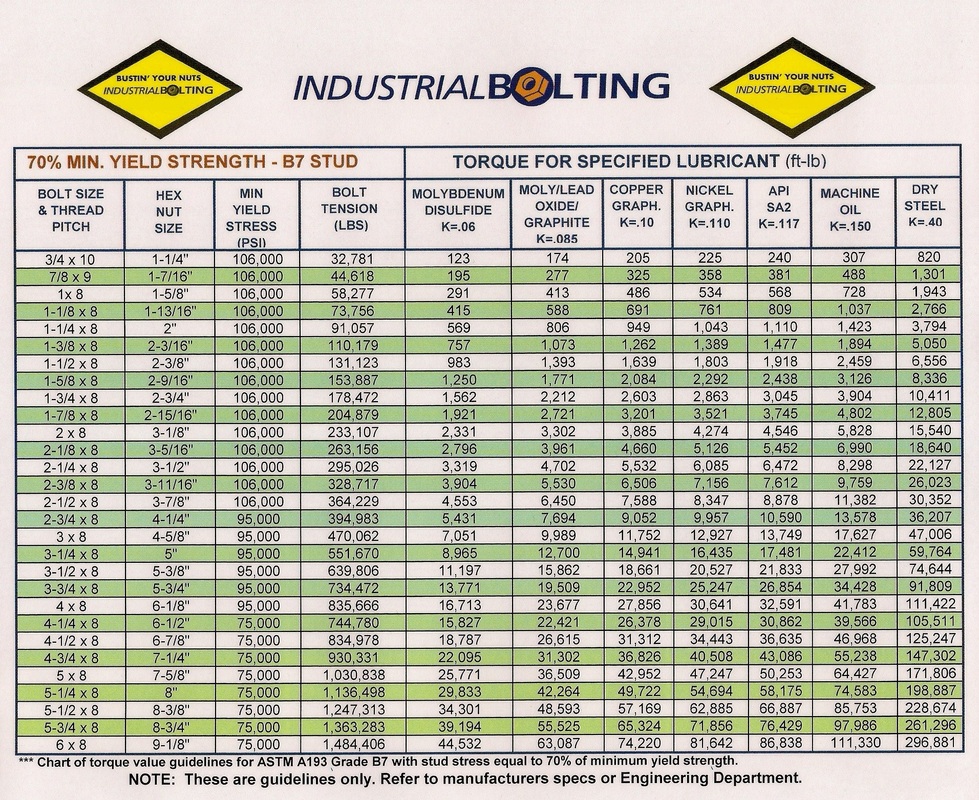

Torque Flange Chart - Ansi 150# flanges ansi 300# flanges ansi 400# flanges. Web a collection of flange bolt chart's reference material on flange torque. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Web class 1500 flange torque charts. Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Flange torque charts listed by nps and by flange class. More torque is applied the nut stretches the bolt. Web torque values for bolts greater than 1.1/2 in. 1135 psi hydro test pressure: Diameter are based on 30 ksi yield strength. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. Links to the flange torque charts maintained by flange bolt chart for class 1500 flanges. Central plastics company does not take responsibility for any of these torque values, they're theoretical values. Class 2500 flange torque charts. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) Class 2500 flange torque charts. Diameter are based on 30 ksi yield strength. Parent page for flange bolt chart material related to flange torque. Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Bolting torque to develop 70% bolt yield stress at nut factor, k=0.16. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) Minimum preferred torque torque (ft.lbs.) (ft.lbs.) jacketed gasket. Web torque values for bolts greater than 1.1/2 in. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. Based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. * use this the data from this program at your own risk and responsibility. Web links to the flange torque charts maintained by flange bolt chart for class 600 flanges. Bolting torque to develop 70% bolt yield stress at nut factor, k=0.16. Flange torque charts listed by nps and by flange class. Target % of yield ? Minimum preferred torque torque (ft.lbs.) (ft.lbs.) jacketed gasket. Based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Web class 1500 flange torque charts. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Web torque values for bolts greater than 1.1/2 in. Lookup bolt lengths, wrench sizes,. Flange torque charts listed by nps and by flange class. Class 2500 flange torque charts. Web these torque values are intended for use as quidelines only & are based on perfect conditions. Diameter are based on 30 ksi yield strength. Web class 1500 flange torque charts. The above table is applicable only for astm a320 grade l7. Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Using a calibrated torque wrench (manual or hydraulic torque wrench), flange bolttorque can be measured during flange assembly. Flange torque charts listed by nps and by flange class. 1135 psi hydro test pressure: Lookup bolt lengths, wrench sizes,. Central plastics company does not take responsibility for any of these torque values, they're theoretical values. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Class 600 flange torque charts listed by nominal pipe size. Target % of yield ? Web torque values for bolts greater than 1.1/2 in. Flange bolt size chart and torque patterns. Flange torque charts listed by nps and by flange class. The above table is applicable only for astm a320 grade l7. Target % of yield ? Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. K = 0.15 k = 0.17 k = 0.20. Web links to the flange torque charts maintained by flange bolt chart. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Web links to the flange torque charts maintained by flange bolt chart for class 600 flanges. Flange torque charts listed by nps and by flange class. Diameter are based on 30 ksi yield strength. Using a calibrated torque wrench (manual or hydraulic torque wrench), flange bolttorque can be measured during flange assembly. Web class flanges bolt torque loads. Flange bolt size chart and torque patterns. In this article, you will learn about the torque sequence of pipe flanges. Central plastics company does not take responsibility for any of these torque values, they're theoretical values. Target % of yield ? Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. Links to the flange torque charts maintained by flange bolt chart for class 1500 flanges. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb.

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Torque Charts Industrial Bolting and Torque Tools

Torque Charts Industrial Bolting and Torque Tools

Metric Bolt Tightening Torque Chart images

Pipe Flange Torque Chart

![API 6A Spec Flange Bolt Ring Chart Tap End [PDF Document]](https://cdn.vdocuments.mx/img/1200x630/reader015/image/20181030/55cf9747550346d03390b9bc.png?t=1592059553)

API 6A Spec Flange Bolt Ring Chart Tap End [PDF Document]

Torque Charts Industrial Torque Tools

Torque Charts Industrial Bolting and Torque Tools

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Pipe Flange Bolt Torque Chart

K = 0.15 K = 0.17 K = 0.20.

Minimum Preferred Torque Torque (Ft.lbs.) (Ft.lbs.) Jacketed Gasket.

This Torque Creates An Axial Force In The Bolt.

More Torque Is Applied The Nut Stretches The Bolt.

Related Post: