Troubleshooting Sewing Machine Tension Chart

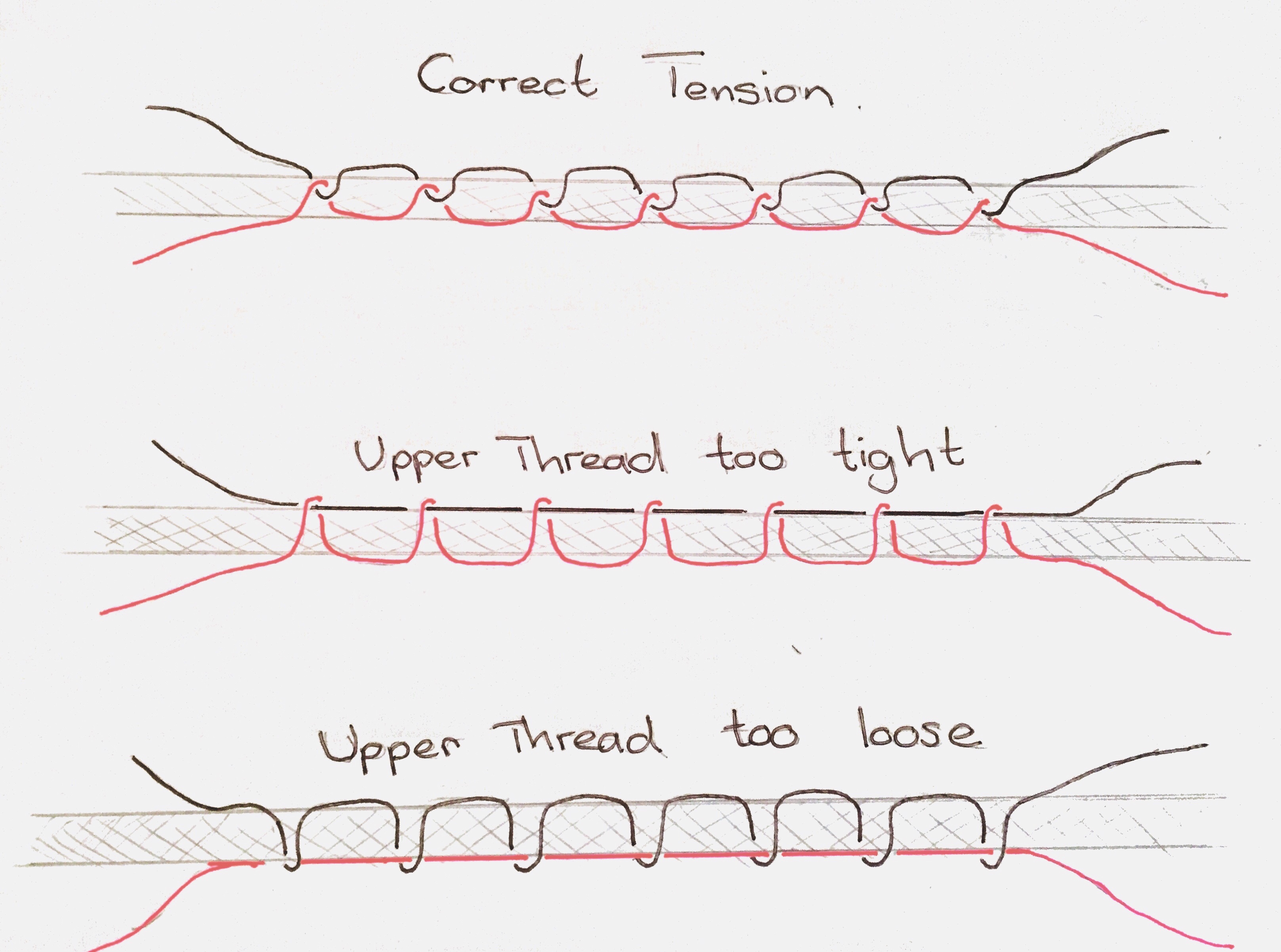

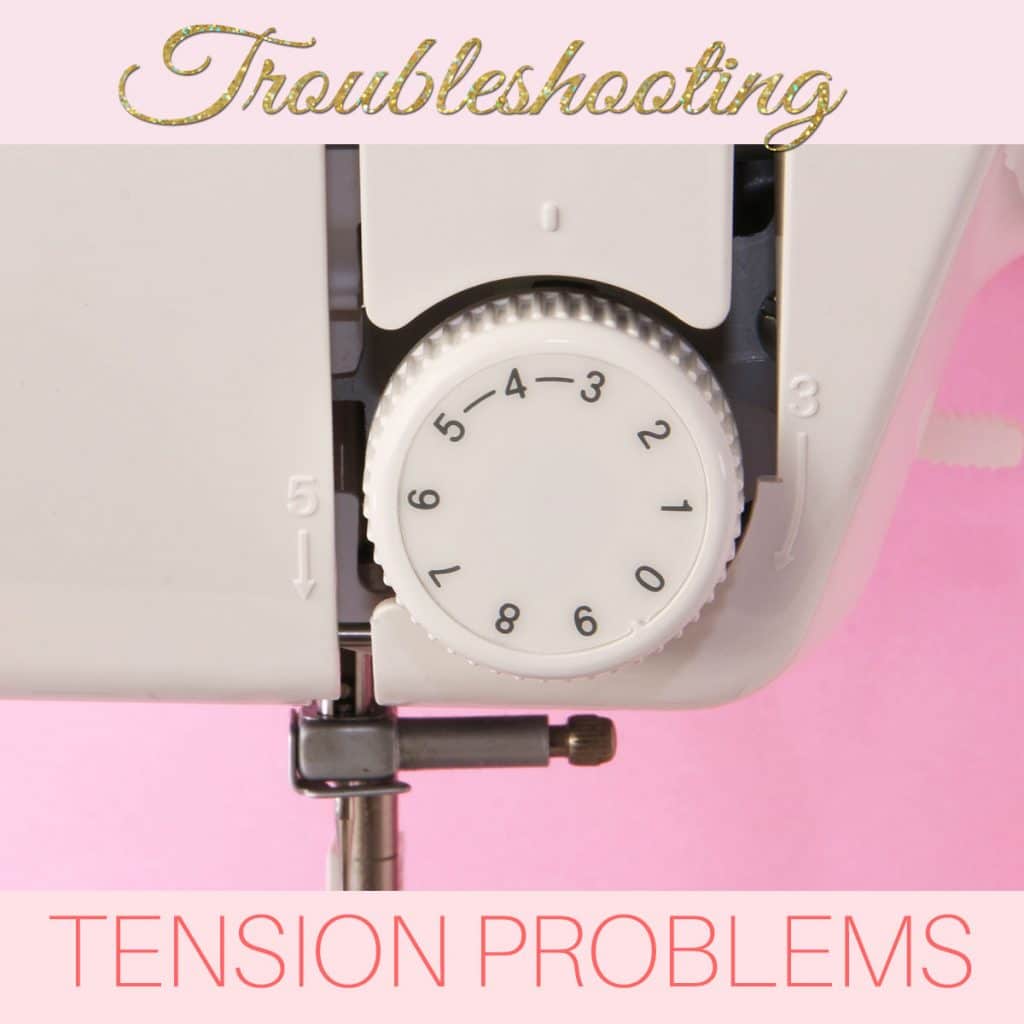

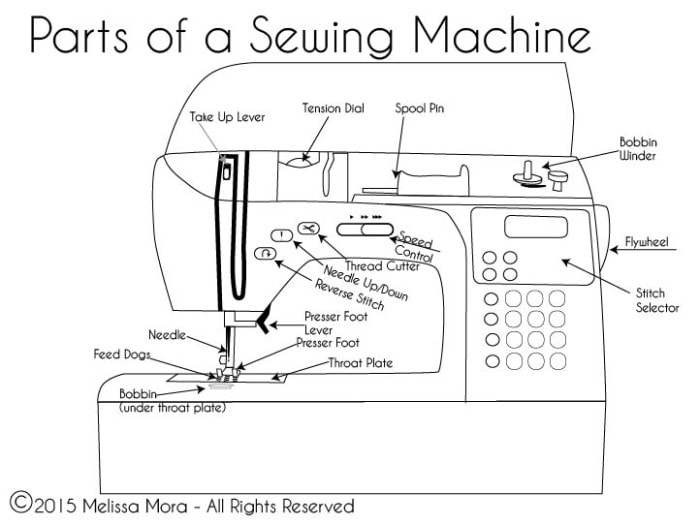

Troubleshooting Sewing Machine Tension Chart - Sewing machine tension issues can be frustrating and may result in uneven stitches, thread and needle breaks, and other sewing problems. Also, check it is correctly inserted into the needle holder. Check the sewing machine needle and replace it if necessary. Web first, use the white or black thread in the bobbin and the other for upper threading. Web let's look at one way to troubleshoot the problem before you make changes to the sewing machine's needle or bobbin tension settings: Follow this sewing machine tension guide to learn how to make the most of your sewing machine’s. And one of them is the type of fabric you are stitching. Find the tension discs and regulator. The flat part of the needle should be at the back. They are various loops that you run the thread through before looping it into your needle. Web if you have been struggling with getting the tension settings right on the machine, you have come to the right place. Read on to know every detail about thread tension. The flat part of the needle should be at the back. Grab your sewing machine user's manual. They keep the thread from getting tangled and distribute the tension evenly. Unthread the top thread―the thread that goes through the needle. If you frequently face tension problems, check the following common yet important troubleshooting tips i’ve gathered after comprehensive research. So sit back, thread your needle, and unravel the mysteries of sewing machine tension together! Web at least 90% of the time, any trouble you run into with loose, tight, or. If you want tighter stitches, you would use a higher number; Read our guide to troubleshooting common sewing machine tension issues to learn how to fix and avoid them. Web at least 90% of the time, any trouble you run into with loose, tight, or wobbly stitches comes from incorrect tension in your sewing machine. They keep the thread from. Web first, use the white or black thread in the bobbin and the other for upper threading. Thread the machine with different colors of thread in the needle and bobbin. Even the most experienced sewists may encounter tension problems with their sewing machines at some point. Having the right sewing machine tension is vital to creating consistent stitches on both. Next, double your fabric piece so. Web if you have been struggling with getting the tension settings right on the machine, you have come to the right place. The straight stitches should be even, and in alignment on both sides of the fabric. Web at least 90% of the time, any trouble you run into with loose, tight, or wobbly. If you want tighter stitches, you would use a higher number; They are various loops that you run the thread through before looping it into your needle. And one of them is the type of fabric you are stitching. Web if you have been struggling with getting the tension settings right on the machine, you have come to the right. And one of them is the type of fabric you are stitching. Web first, use the white or black thread in the bobbin and the other for upper threading. Read on to know every detail about thread tension. Web this article will explore some common sewing machine tension problems and provide practical solutions to help you confidently conquer them. If. Web how to fix sewing machine tension problems. Read our guide to troubleshooting common sewing machine tension issues to learn how to fix and avoid them. Web you thread the machine, check your settings, carefully place your fabric, lower the presser foot, and carefully tap down on the petal. Unthread the top thread―the thread that goes through the needle. The. But how do you know when the tension is off? Loopy stitches on the fabric surface. Web if your machine is not sewing nicely or is sounding strange, your sewing machine tension may be too tight or too loose. The flat part of the needle should be at the back. Unthread the top thread―the thread that goes through the needle. Next, double your fabric piece so. This comprehensive guide covers everything you need to know about getting your tension correct. Having the right sewing machine tension is vital to creating consistent stitches on both sides of the fabric. If either the top or bottom thread is loopy, you will need to adjust the tension. Bobbin thread visible on the top. They are various loops that you run the thread through before looping it into your needle. They keep the thread from getting tangled and distribute the tension evenly from the spool to your fabric. Is it really a sewing machine tension problem? Remove the bobbin (and its case) and clean the bobbin area of the machine as directed in your. A number of factors impact the tension settings on a sewing machine. Simply put, if the tension isn’t balanced, your stitches may either be too loose or too tight, potentially ruining the look and strength of that beautiful project you’re working on. Sew 6 inches or so, and look at the fabric’s right and wrong sides. A bent or blunt needle can cause your tension to go out. Web you thread the machine, check your settings, carefully place your fabric, lower the presser foot, and carefully tap down on the petal. If you frequently face tension problems, check the following common yet important troubleshooting tips i’ve gathered after comprehensive research. This comprehensive guide covers everything you need to know about getting your tension correct. Checking your threading and bobbin placement before stitching eliminates two factors that could affect the stitches made. If you want tighter stitches, you would use a higher number; Web at least 90% of the time, any trouble you run into with loose, tight, or wobbly stitches comes from incorrect tension in your sewing machine. Web this article will explore some common sewing machine tension problems and provide practical solutions to help you confidently conquer them. You’re left with a messy jumble of thread and.

Oh You Crafty Gal Sewing Lesson 10 How to Fix Tension on Your Sewing

How to set/adjust TENSION REGULATOR PROBLEM in Singer sewing machines

Sewing Machine Tension Chart The Ultimate Guide Craftbuds

Sewing Machine Tension Guide

UNDERSTANDING THREAD TENSION ON YOUR SEWING MACHINE

Sewing Machine Tension Adjustment

Sewing Machine Tension Chart

Sewing Machine Troubleshooting Solve Problems Fast personal Custom

Sewing Machine Tension Numbers

A Step By Step Guide to Understanding Sewing Thread Tension Melly Sews

Web Begin By Making Test Swatches.

Web Nicki Begins By Talking About The Basics Of Sewing Machine Tension And Explaining Some Of The Different Issues That Unbalanced Tension Can Cause, Like Skipped Stitches, Thread Breakage, Thread Nests, And Many Other Stitch Quality Problems.

Test A Scrap Of Fabric And See If The Upper And Lower Threads Are Both Even And Uniformly Formed.

Also, Check It Is Correctly Inserted Into The Needle Holder.

Related Post: