Tungsten Amperage Chart

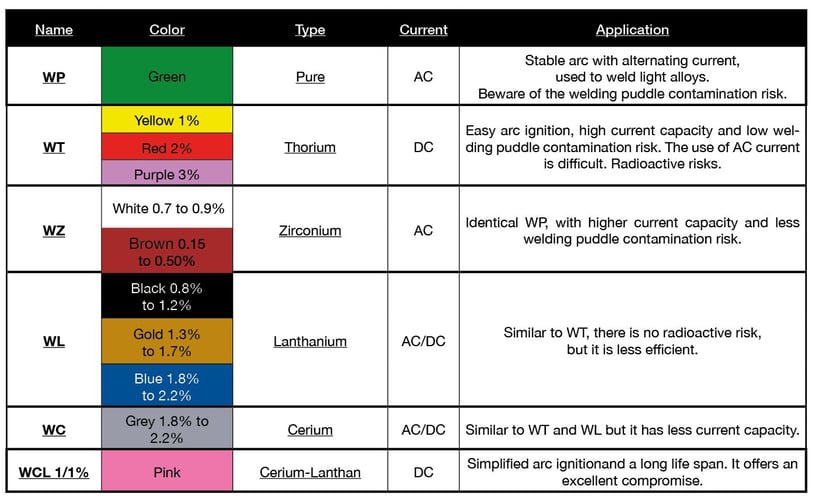

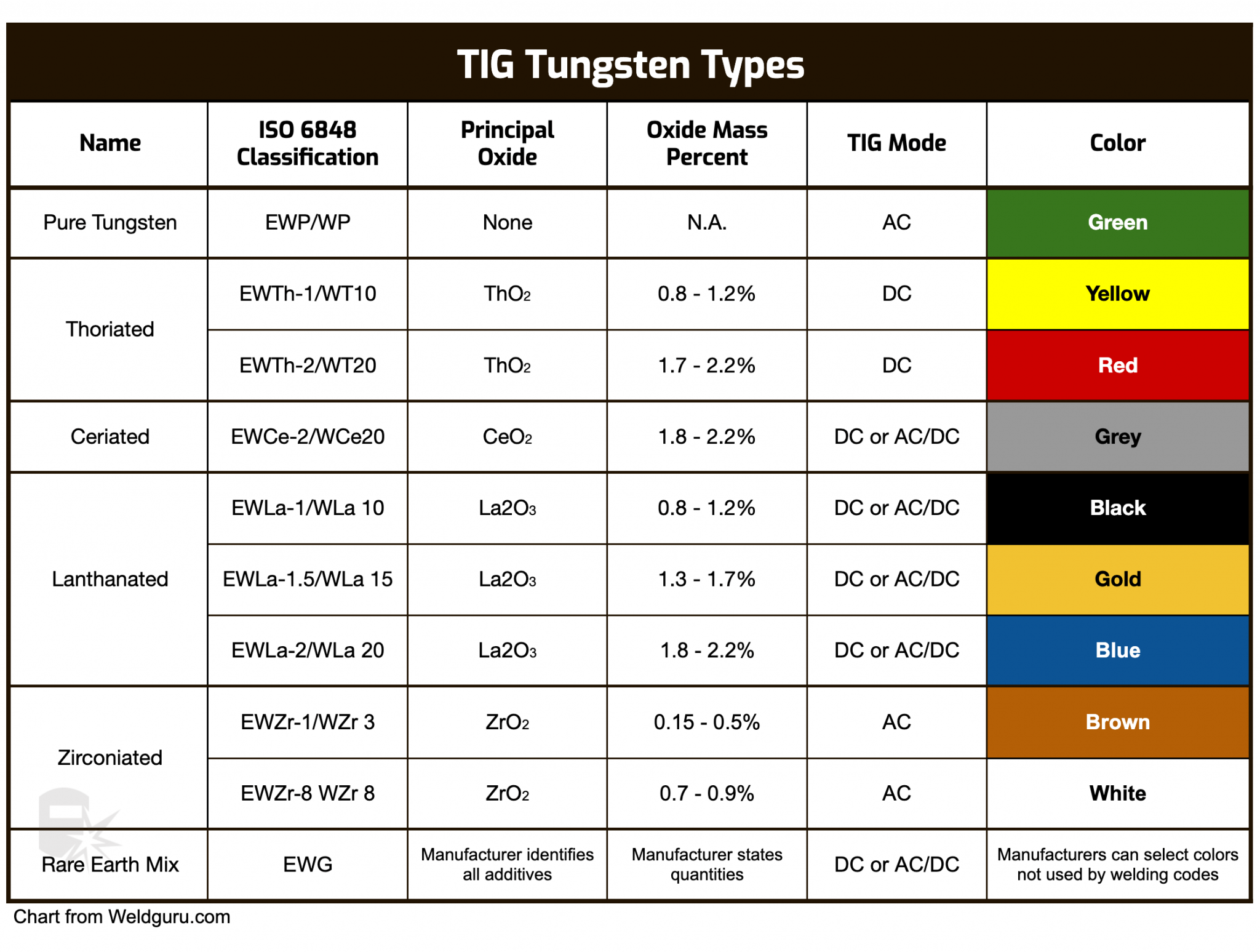

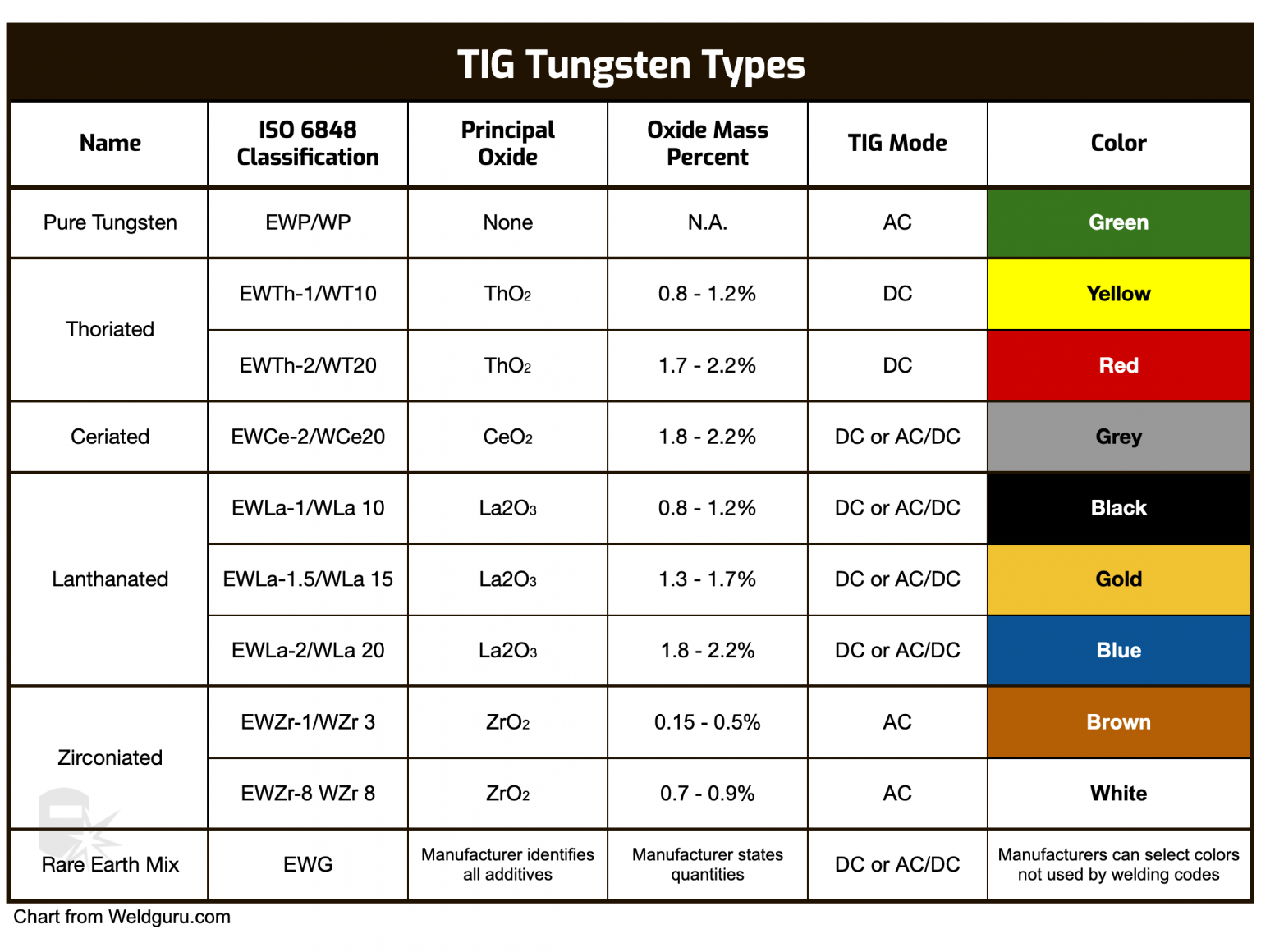

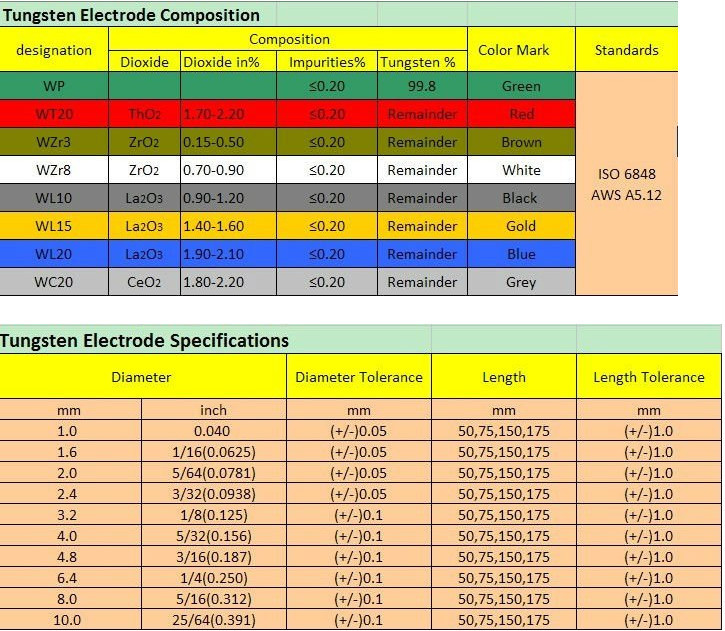

Tungsten Amperage Chart - Web when choosing a tungsten electrode’s composition, diameter, and tip shape, you should consider: Diameter of f lat spot determines amperage capacity. Selecting the right tungsten electrode. Remove the sharp point to leave a truncated point with a f lat spot. Click the chart to get the full size. Different electrode materials will vary slightly from these guidelines. Web what are the main types of tungstens used for welding? Welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding. Common questions when selecting a tungsten type. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct. Web 12 rows current ranges for tungsten electrodes. Information on specifications and usage. Web keep in mind that for a given amount of amperage, larger diameter electrodes will last longer, but will be harder to arc start. Web all values listed are based on using argon as the shielding gas. Common questions when selecting a tungsten type. Remove the sharp point to leave a truncated point with a f lat spot. Use of other gases will also change the. Web the 0.8% zirconiated electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten splitting. Web for example, the chart below shows amperage ranges along with the proper diameter of tungsten for. Web along with that, you should also know the suitable amperage needed for the job based on the size of the electrode as well as the type of current you are using for the. As an example, the following table lists the electrical. Web 12 rows current ranges for tungsten electrodes. Excessive current will cause the electrode to melt. Web. As we progress through this guide of tig welding electrodes, it’s important to know that there. Common questions when selecting a tungsten type. Web when choosing a tungsten electrode’s composition, diameter, and tip shape, you should consider: Different electrode materials will vary slightly from these guidelines. Web in this article, we will explore the world of tig tungsten electrodes, their. Welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding. Remove the sharp point to leave a truncated point with a f lat spot. • the amperage range needed • the shape and thickness of the welded metal. Web for example, the chart below shows amperage ranges along with the proper diameter of tungsten. Web what are the main types of tungstens used for welding? Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Web along with that, you should also know the suitable amperage needed for the job based on the size of the electrode. Selecting the right tungsten electrode. Use of other gases will also change the. Diameter of f lat spot determines amperage capacity. Web 7 premium electrode varieties. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct. Diameter of f lat spot determines amperage capacity. Web all values listed are based on using argon as the shielding gas. Common questions when selecting a tungsten type. You need to select a diameter large enough to accommodate the. General tungsten amperage chart by diameter and alloying element. Web for example, the chart below shows amperage ranges along with the proper diameter of tungsten for welding stainless steel using argon shielding gas: As an example, the following table lists the electrical. • the amperage range needed • the shape and thickness of the welded metal. Selecting the right tungsten electrode. Web the tungsten electrodes required for tig welding. Web the 0.8% zirconiated electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten splitting. The color chart below summarizes the various tig tungsten electrodes you may come across: Web the diameter of the tungsten and amperage required is also dependent on the base metal being welded. Information on specifications and usage. Welders are. • the amperage range needed • the shape and thickness of the welded metal. The color chart below summarizes the various tig tungsten electrodes you may come across: Web along with that, you should also know the suitable amperage needed for the job based on the size of the electrode as well as the type of current you are using for the. Web all values listed are based on using argon as the shielding gas. Click the chart to get the full size. Web how do i select an amperage level for tig welding? General tungsten amperage chart by diameter and alloying element. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Web what are the main types of tungstens used for welding? Excessive current will cause the electrode to melt. Web keep in mind that for a given amount of amperage, larger diameter electrodes will last longer, but will be harder to arc start. Remove the sharp point to leave a truncated point with a f lat spot. Pure tungsten electrodes provide good stability when welding with alternating (“ac”) but may be used with direct. Web 7 premium electrode varieties. Use of other gases will also change the. Welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding.

The different types of electrodes used in orbital TIG welding

Choose The Perfect Tungsten TIG Welding With Canaweld

TIG Tungsten Electrodes Explained (with Color Chart)

2022 Haili Brand Premium Tig Welding Ground Finish Wt20 2.4mmx175mm

The different types of electrodes used in orbital TIG welding

Tig Tungsten Chart Labb by AG

TIG Tungsten Electrodes Explained (with Color Chart)

Tungsten Welding Electrode Color Chart Colorxml

Tungsten Electrode Sharpener Buy Tungsten Electrode Sharpener,Wt20

TIG Tungsten Electrodes Explained (with Color Chart)

Web For Example, The Chart Below Shows Amperage Ranges Along With The Proper Diameter Of Tungsten For Welding Stainless Steel Using Argon Shielding Gas:

Charlotte, Nc 28216 Www.weldingwire.com :$6+,1*721$/ /2<¶6 Ity Management System.

Selecting The Right Tungsten Electrode.

Web The Tungsten Electrodes Required For Tig Welding Come In Various Sizes And Types, Each Working With Varying Amperage.

Related Post: