Tungsten Welding Chart

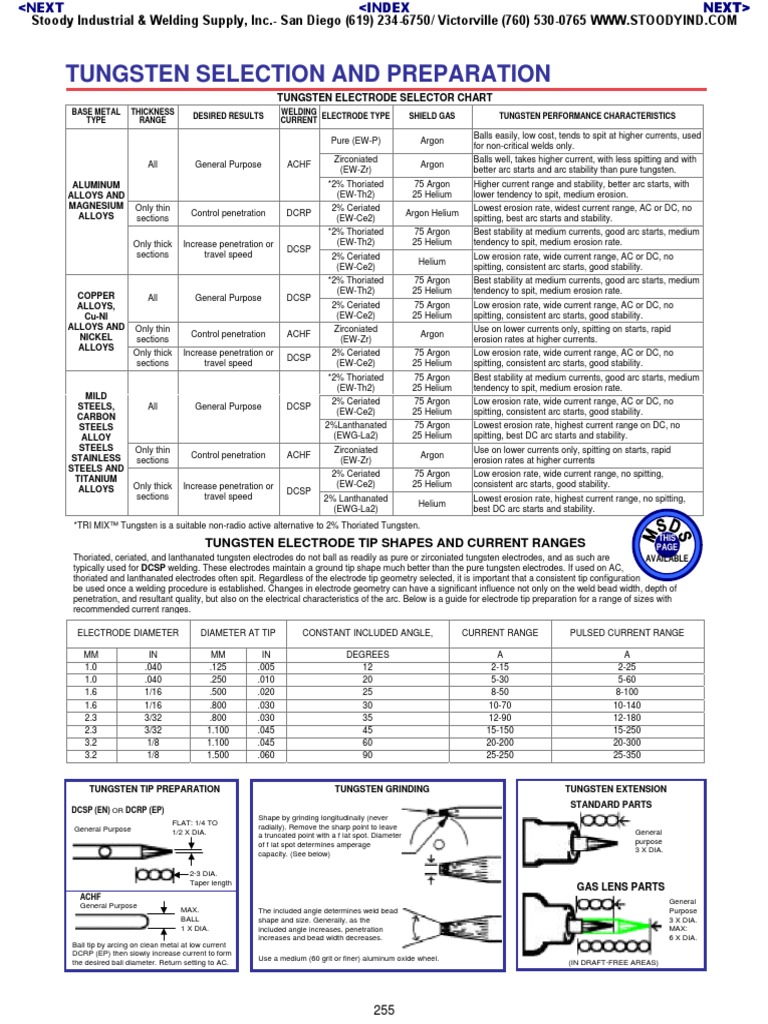

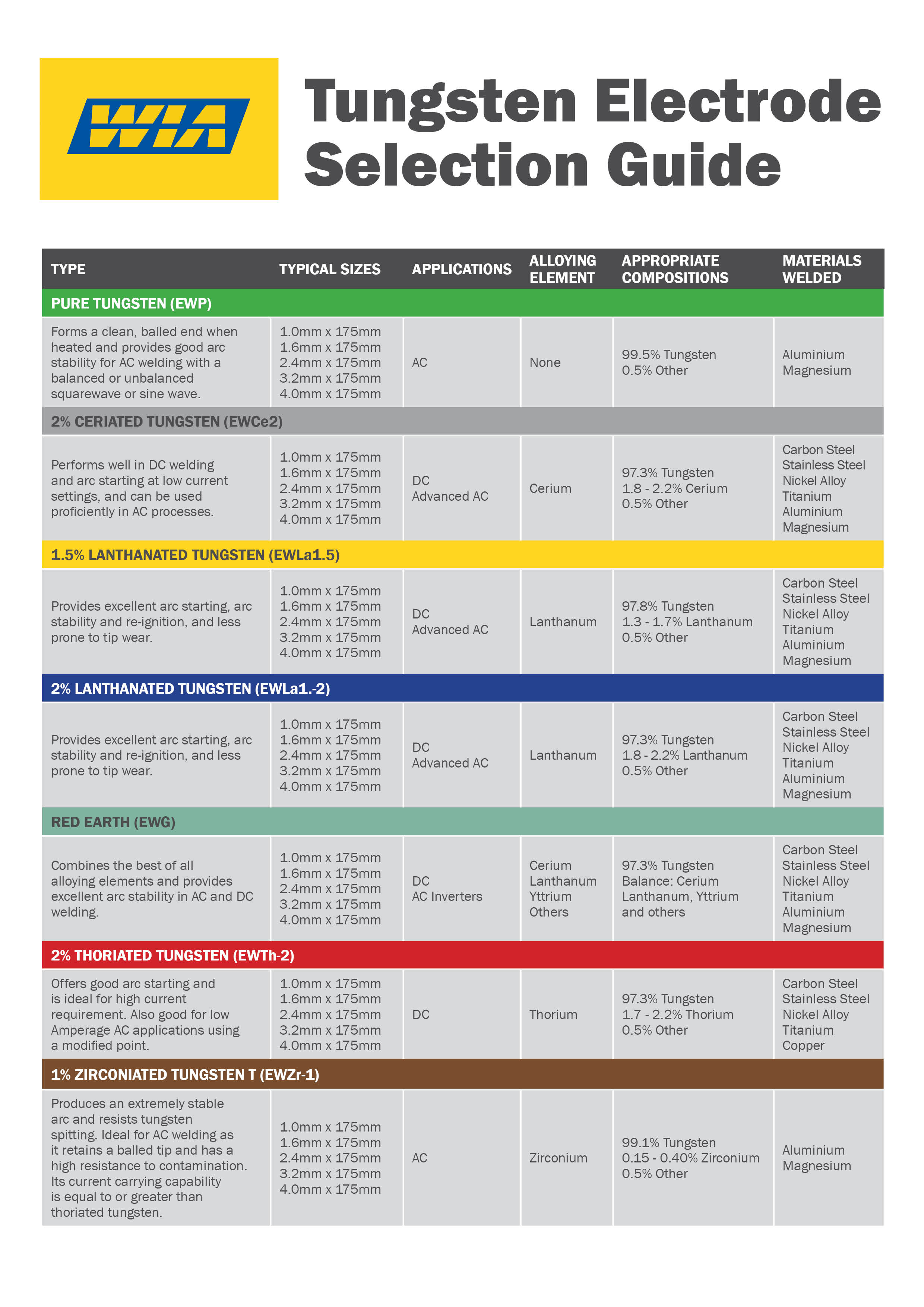

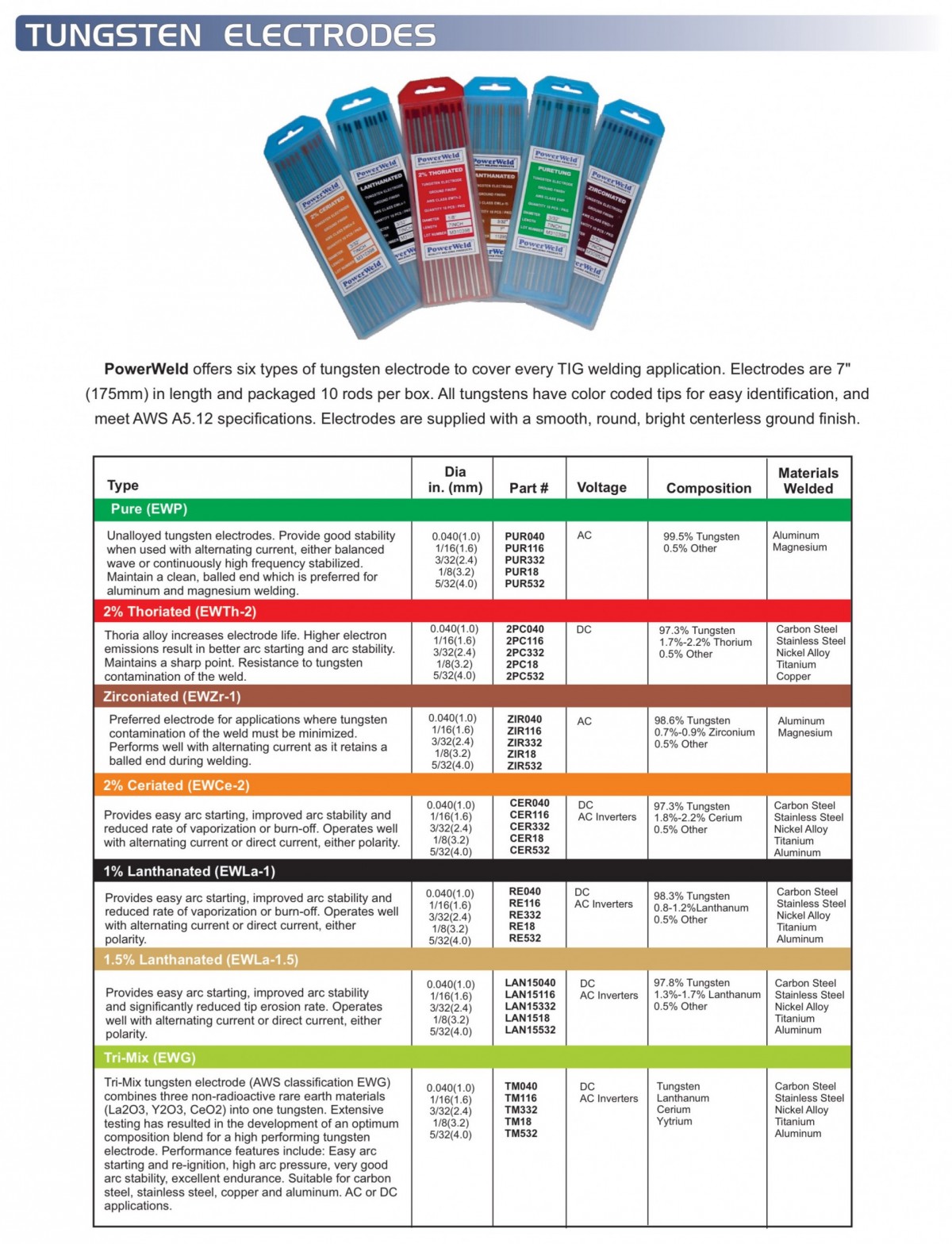

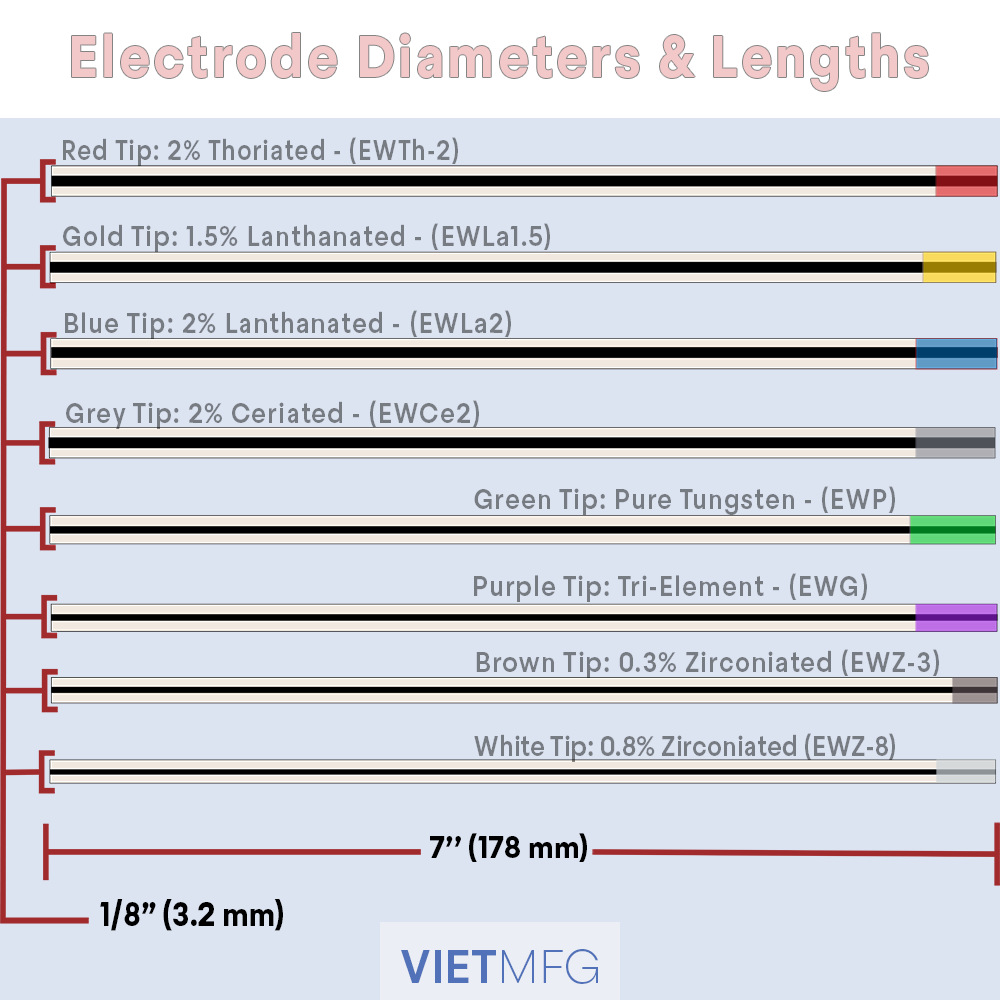

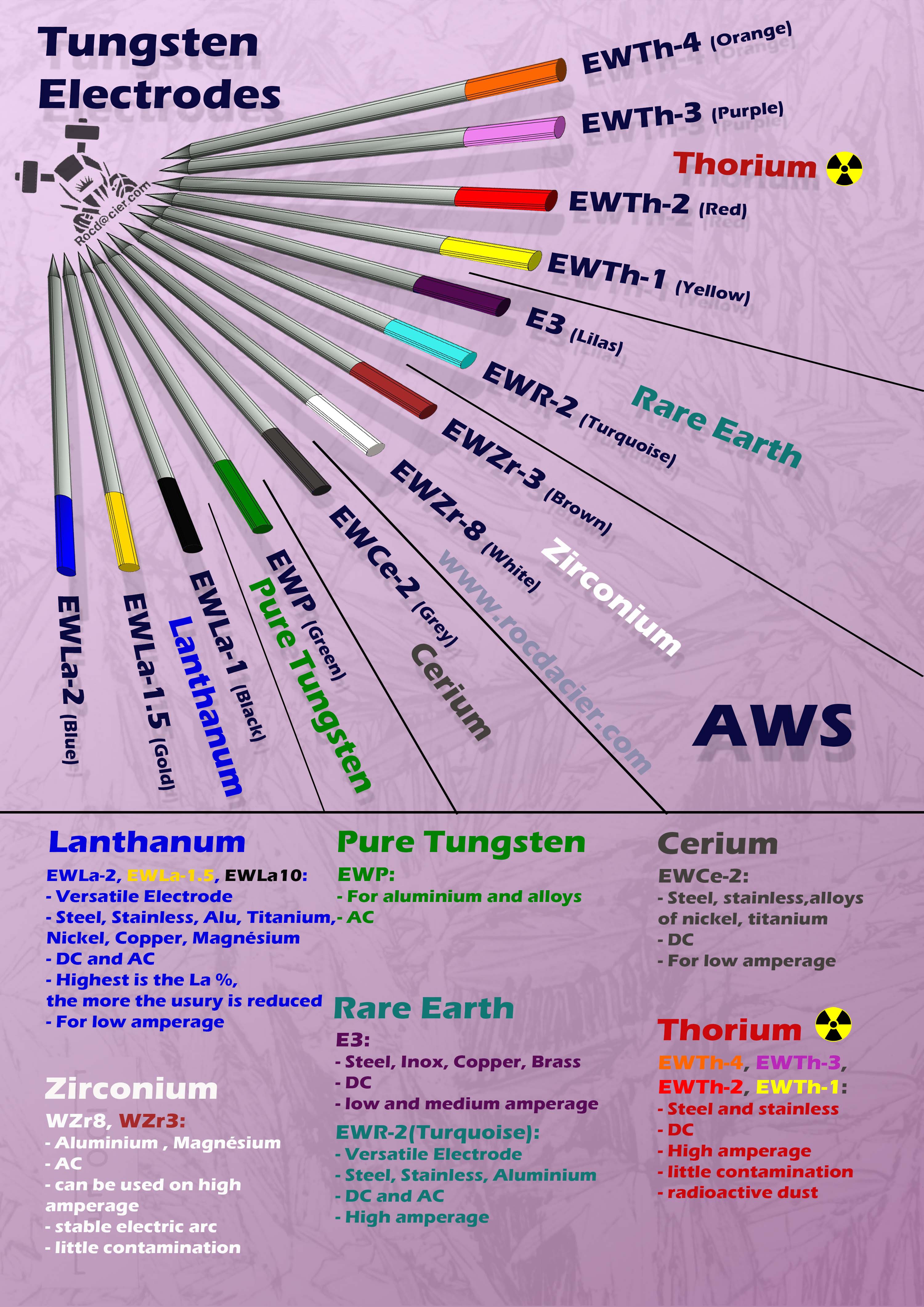

Tungsten Welding Chart - Learn from ron covell about the different tungsten electrodes available for a variety of welding applications. Web tungsten is a robust metal with unique properties commonly used for the manufacturing of welding electrodes. Web nearly sixty years of experience have gone into producing these premium quality tig welding tungsten electrodes, and you benefit from that experience. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Tungsten and performs best in ac/dc welding applications. Shape by grinding longitudinally (never radially). Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l The chart lists all of the common tungsten colors and their corresponding temperatures. Maximizing the benefits of inverter technology in ac tig welding depends on many factors. These gtaw torch parts are common across most types of gtaw welding machines, with the differences being in how these elements are adapted to different roles. Web tungsten and oxide dispersed tungsten electrodes for arc welding and cutting. Web tig welding allows the welder more control. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. These gtaw torch parts are common across most types of gtaw welding machines, with the differences being in how these elements are adapted to different roles. There. Web 7 premium electrode varieties. It is also the most economical of all tungsten electrodes. Web tungsten is a rare metallic element used for manufacturing gas tungsten arc welding (gtaw) electrodes. Web tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Green tig welding electrodes are pure tungsten and are used for ac. Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l Correctly matching the tungsten electrode with a weld’s requirements saves time and money. Tungsten and performs best in ac/dc welding applications. The additives in a tungsten electrode change its properties in ways both subtle and large. Benefits of. The american welding society document provides a table that shows the general current ranges for tungsten using direct current (dc) and alternating current (ac). Web how to choose the best tungsten for ac tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Print this selection chart and keep it. Tungsten and performs best in ac/dc welding applications. Remove the sharp point to leave a truncated point with a f lat spot. Web what are the main types of tungstens used for welding? Benefits of pure tungsten electrodes advantages: It is also the most economical of all tungsten electrodes. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Web tungsten is a rare metallic element used for manufacturing gas tungsten arc welding (gtaw) electrodes. Tungsten and performs best in ac/dc welding applications. Web selecting the right tungsten electrode is an essential. However, they also burn up much faster than the other alloy electrodes, so prepare to stock up if you go this route. These gtaw torch parts are common across most types of gtaw welding machines, with the differences being in how these elements are adapted to different roles. Web 7 premium electrode varieties. The current polarity, power source, thickness of. Trying to find the perfect tungsten electrode for the tig weld you’re planning can seem like a bit of a mission. Tig welding electrodes usually contain small quantities of metallic oxides which can offer increase arc stability, facilitate arc starting, increase electrode l Web nearly sixty years of experience have gone into producing these premium quality tig welding tungsten electrodes,. The american welding society document provides a table that shows the general current ranges for tungsten using direct current (dc) and alternating current (ac). Web tungsten is a robust metal with unique properties commonly used for the manufacturing of welding electrodes. Green tig welding electrodes are pure tungsten and are used for ac welding, often for aluminum and magnesium. Benefits. However, they also burn up much faster than the other alloy electrodes, so prepare to stock up if you go this route. There are quite a few tungsten types on the market, and every single one of them does something different, even if it’s just slightly. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. Web. Web 7 premium electrode varieties. Tungsten has the highest melting point of any metal, 3,410 degrees celsius. Luckily, each tungsten stick has a color code applied to one end, which identifies the material type of the tungsten. The american welding society document provides a table that shows the general current ranges for tungsten using direct current (dc) and alternating current (ac). All values listed are based on using argon as the shielding gas. It has the highest tensile strength of any metal and can retain it even at a high melting point of all at 3422° c (6192° f). The additives in a tungsten electrode change its properties in ways both subtle and large. These gtaw torch parts are common across most types of gtaw welding machines, with the differences being in how these elements are adapted to different roles. However, they also burn up much faster than the other alloy electrodes, so prepare to stock up if you go this route. Web what are the main types of tungstens used for welding? Ball tip by arcing on clean metal at low current dcrp (ep) then slowly increase current to form the desired ball diameter. Tungsten and performs best in ac/dc welding applications. These electrodes are vital to the process, channeling the current necessary to. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Web tungsten is a rare metallic element used for manufacturing gas tungsten arc welding (gtaw) electrodes. Web tungsten electrodes for tig/ plasma welding are classified and designated according to the aws a5.12 and iso 6848 standard.

TIG Tungsten Electrodes Explained (with Color Chart)

Tig Welding Tungsten Chart

TIG Welding Tungsten Electrode Selection Chart Midwest Tungsten Service

Choose The Perfect Tungsten TIG Welding With Canaweld

TIG Tungsten Electrodes Explained (with Color Chart)

Tungsten Electrode Chart Welding Metals

![Tips For Selecting Tungsten Electrodes [TIG Welding]](https://weldingpros.net/wp-content/uploads/2020/04/tungsten-electrodes.jpg)

Tips For Selecting Tungsten Electrodes [TIG Welding]

Tungsten Electrode Selection Chart

Tungsten Welding Electrode Color Chart Colorxml

Tig Tungsten Electrode Chart

Benefits Of Pure Tungsten Electrodes Advantages:

A Summary Of Tungsten Electrode Designation, Type Of Oxide, And Tip Color Is Given In The Below Picture For Reference.

They Tend To Be Commonly Used Because They Are Inexpensive.

The Current Polarity, Power Source, Thickness Of The Material, And Metal Type Play A Role In Tungsten Selection.

Related Post: