Welding Amperage Chart

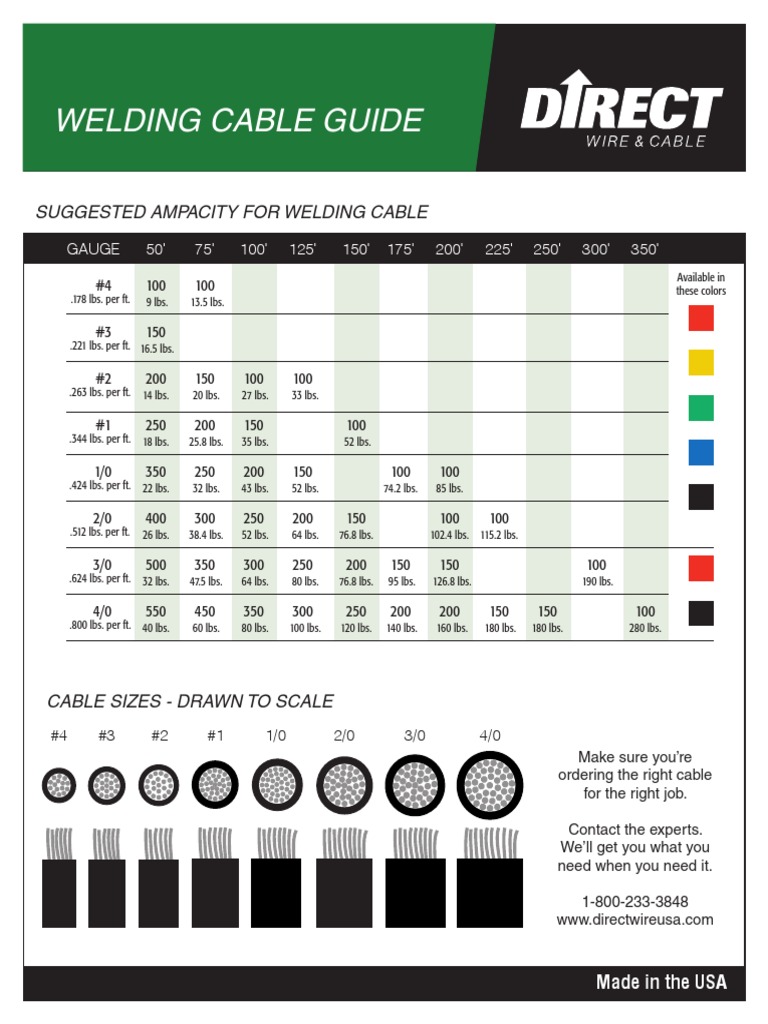

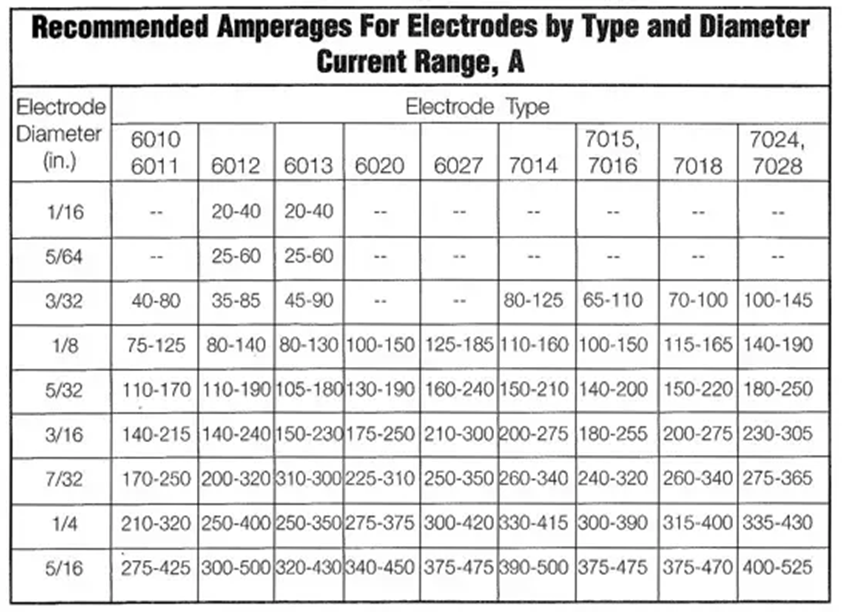

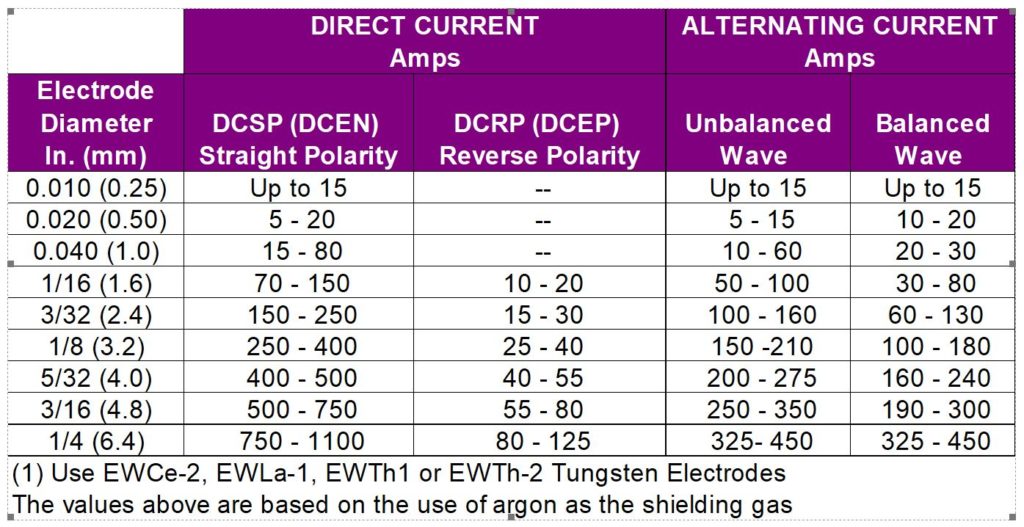

Welding Amperage Chart - Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Web printable electrode amperage chart. Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. Twist the regulator valve to set how much gas flow you want for the weld. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Before tackling any mig welding application, look at the charts and tips below. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Web the chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position being used. What are the common sizes of tig welding rods? Take a look at table 1: Tig welding chart based on material and shielding gas. Browse suggested weld parameter settings for tig welding. Before tackling any mig welding application, look at the charts and tips below. 7014 welding rod amperage chart. Take a look at table 1: Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Diameter (inches) diameter (mm) 6010/6011. 7014 welding rod amperage chart. Before delving into amperage settings, it's essential to understand the characteristics of the stick electrodes you're using. Tig welding chart based on material and shielding gas. Web our powerful calculator let's you easily determine which stick electrode you need. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. What are the common sizes of tig welding rods? 7014 welding. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Take a look at table 1: Twist the regulator valve to set how much gas flow you want for the weld. Web as a guideline, each.001 inch of material thickness requires 1. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Web look at the tig welding amperage charts below for information to help you with any weld, no matter the material, size, or anticipated outcome. 6013 welding rod amperage chart. Web welding. Tig welding chart based on material and shielding gas. So, how many amps does it take to weld 3/8 steel? Web our powerful calculator let's you easily determine which stick electrode you need. That's because as the welding current increases, the weld penetrates deeper into the base material. What are the common sizes of tig welding rods? Since you don't want to change wire, select one for your most commonly used thicknesses. Once you determine these three main variables, you can set your welding machine and start. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Tig welding chart based on material and shielding gas. Web one shows how. Twist the regulator valve to set how much gas flow you want for the weld. Web what material are you welding? Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Diameter (inches) diameter (mm). 6013 welding rod amperage chart. Take a look at table 1: Web one shows how much gas is still in the tank, and the second shows your gas flow rate. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Web once you’ve chosen your welding rod diameter, use the stick welding. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Web what material are you welding? The table is published in aws a5.1 specification. Understanding stick welding rod classification is essential in selecting the correct. Before delving into amperage settings, it's essential to understand the characteristics of the stick electrodes you're using. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Web one shows how much gas is still in the tank, and the second shows your gas flow rate. Web our powerful calculator let's you easily determine which stick electrode you need. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Web welding rod sizes with amperage chart. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. So, how many amps does it take to weld 3/8 steel? Browse suggested weld parameter settings for tig welding. Web the chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position being used. Web what material are you welding? Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. Electrode amperage chart | types and thicknesses. .125 inch = 125 amps. Plus you'll get the most complete welding rod chart on the internet in pdf!Welding Cable Size Amperage Chart

What are a reasonable rods to use ? Welding Site

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

Welding Amps And Volts Chart

Welding Amps To Metal Thickness Chart

Tig Weld Amp Chart

Tig Welding Amperage Chart

Welding Rod Amp Chart

7018 1/8 Welding Rod Amperage Chart

Metal Thickness Stick Welding Amperage Chart

The Amperage Required When Tig Welding Is Highly Affected By The Type Of Metal You Are Working With And How Thick That Metal Is.

Web See Our Chart And Guide On How To Select The Right Welding Rod Size Diameter And Amperage Depending On Metal Thickness And Other Variables.

Use The Charts Provided To Help You Choose The Best Setup For Each Application.

Browse Suggested Weld Parameter Settings For Stick Welding.

Related Post: