Welding Rod And Amp Chart

Welding Rod And Amp Chart - Use a high amperage on thicker metal and a low amperage on thinner metal. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Web when choosing a rod diameter, use the stick welding rod chart at the top of this page to find out the amperage range for that specific electrode. For many contractors, stick welding is at the heart of their business. Web using a welding amperage chart is an effective way to determine the appropriate amperage range for different welding applications. Web a good starting point for setting your amperage is to choose an amperage in the exact middle of the range for a horizontal fillet weld. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Contents [ show] common stick welding rods. Browse suggested weld parameter settings for stick welding. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Web welding rods play a crucial role in determining the quality, strength, and characteristics of the weld, making it essential for welders to choose the right type and size of welding rod based on the welding process and the materials being joined. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable. Plus a chart with rod size and amperage per metal thickness in inches and mm. So what are the other letters and numbers on the label? Diameter (inches) diameter (mm) 6010/6011. We have gone into this in more detail below. This help determines what the various options are designed for and which ones should be used at different times. Plus you'll get the most complete welding rod chart on the internet in pdf! Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. Almost all fusion welding processes require welding electrode to create the weld metal. Welding around this amperage should give good fusion, no sticking and not. Web welding rod sizes with amperage chart. Web a good starting point for setting your amperage is to choose an amperage in the exact middle of the range for a horizontal fillet weld. Plus a chart with rod size and amperage per metal thickness in inches and mm. This chart provides an overview of the most common stick welding rod. Web the e6013 welding rod is a versatile electrode favored by both beginners and professionals in welding due to its excellent arc stability and ability to produce smooth, clean welds with minimal spatter. Welding electrodes & filler rods explained. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Plus you'll get the most complete. Web what material are you welding? Browse suggested weld parameter settings for stick welding. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. Use a high amperage on thicker metal and a low amperage on thinner metal. Web the e6013 welding rod is a versatile electrode favored by both beginners and professionals in welding. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Web the e6013 welding rod is a versatile electrode favored by both beginners and professionals in welding due to its excellent arc stability and ability to produce smooth, clean welds with minimal. Web what material are you welding? Web welding rods play a crucial role in determining the quality, strength, and characteristics of the weld, making it essential for welders to choose the right type and size of welding rod based on the welding process and the materials being joined. Web when choosing a rod diameter, use the stick welding rod chart. Web learn the basics of welding: Web welding rod sizes with amperage chart. An electrode is a metal wire that is coated. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch up to 1/4 inch. Web below is a chart of the different types of stick welding rod and explanations of what the. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch up to 1/4 inch. Web when choosing a rod diameter, use the stick welding rod chart at the top of this page to find out the amperage range for that specific electrode. This chart provides an overview of the most common stick welding rod. A low carbon content means it. Browse suggested weld parameter settings for stick welding. What do welding rod size numbers mean? The table is published in aws a5.1 specification. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch up to 1/4 inch. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Diameter (inches) diameter (mm) 6010/6011. Web the e6013 welding rod is a versatile electrode favored by both beginners and professionals in welding due to its excellent arc stability and ability to produce smooth, clean welds with minimal spatter. This help determines what the various options are designed for and which ones should be used at different times. What are the common sizes of tig welding rods? Web when choosing a rod diameter, use the stick welding rod chart at the top of this page to find out the amperage range for that specific electrode. This chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Contents [ show] common stick welding rods. It is made out of materials with a similar composition to the metal being welded. Web when choosing a rod diameter, use the stick welding rod chart at the top of this page to find out the amperage range for that specific electrode.

Welding Rod Sizes Here's The Complete Guide

Pin by Bill Poole on Metal fabrication Welding and fabrication

Welding Rod Amp Chart

6011 Welding Rod Amperage Chart

What are a reasonable rods to use ? Welding Site

Welding rod chart, Welding rods, Welding and fabrication

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

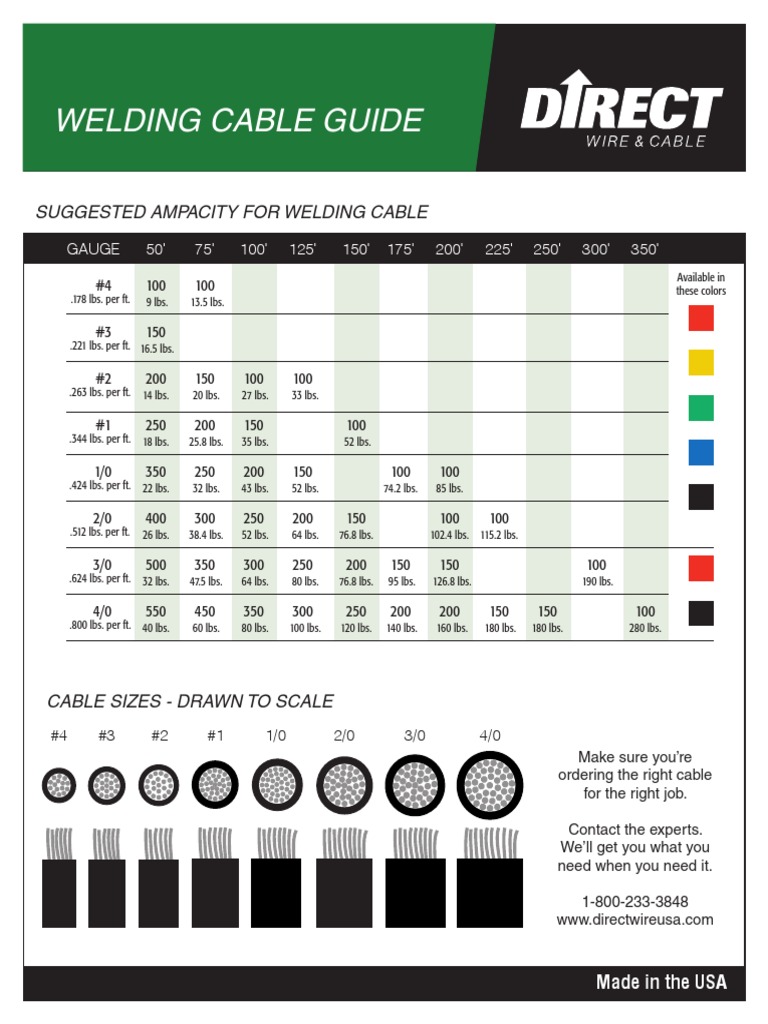

Welding Cable Size Amperage Chart

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding

Stick Welding Rod Charts And Calculator Amps, Sizes, Types, 58 OFF

Use A High Amperage On Thicker Metal And A Low Amperage On Thinner Metal.

For Many Contractors, Stick Welding Is At The Heart Of Their Business.

We Have Gone Into This In More Detail Below.

Web If You Are Looking For Welding Rod Charts, We Created The Ultimate Resource, Listing Everything From Electrode Sizes And Amps To How Much Welding Rod You Need

Related Post: