Wire Rope Size Chart

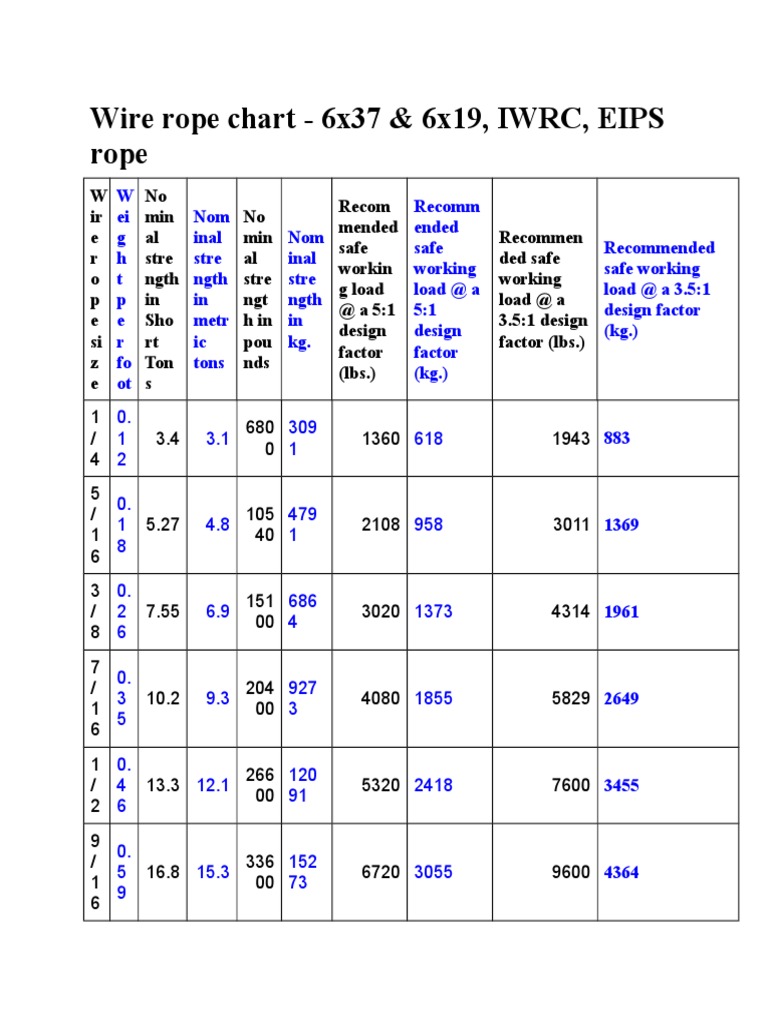

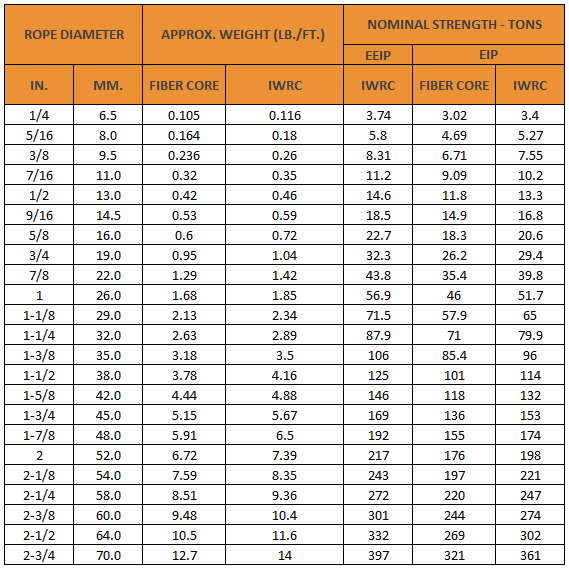

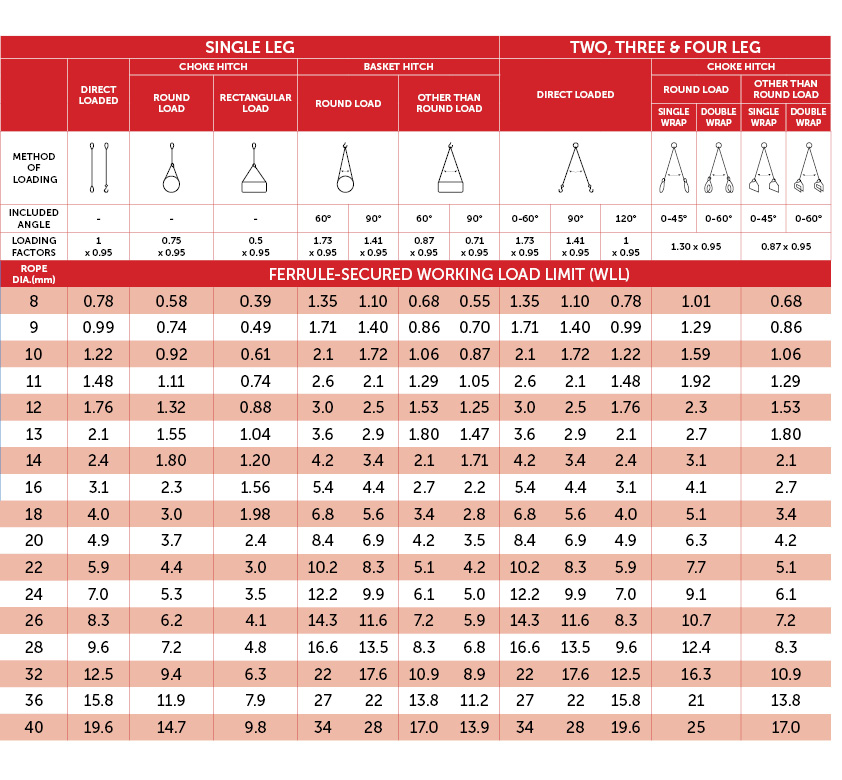

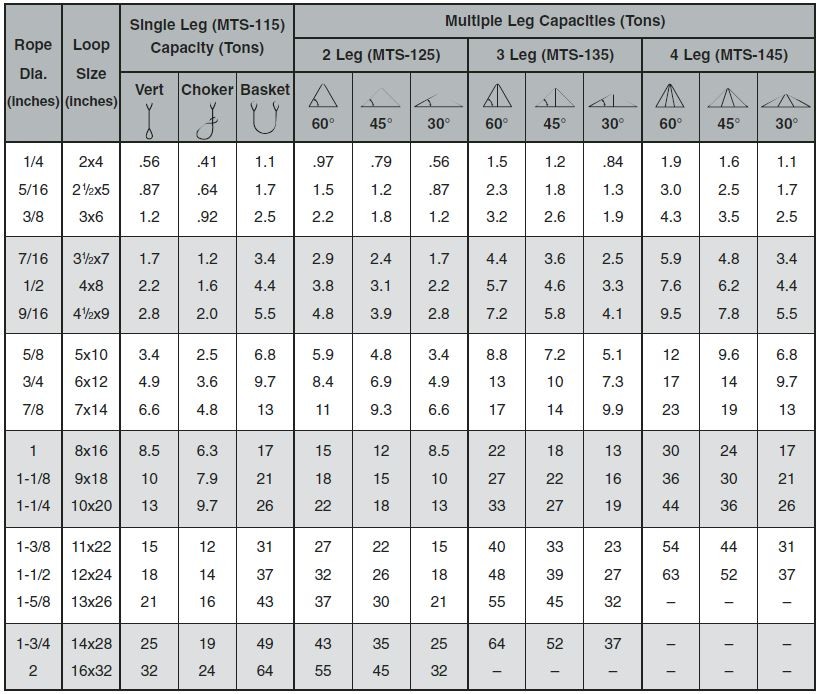

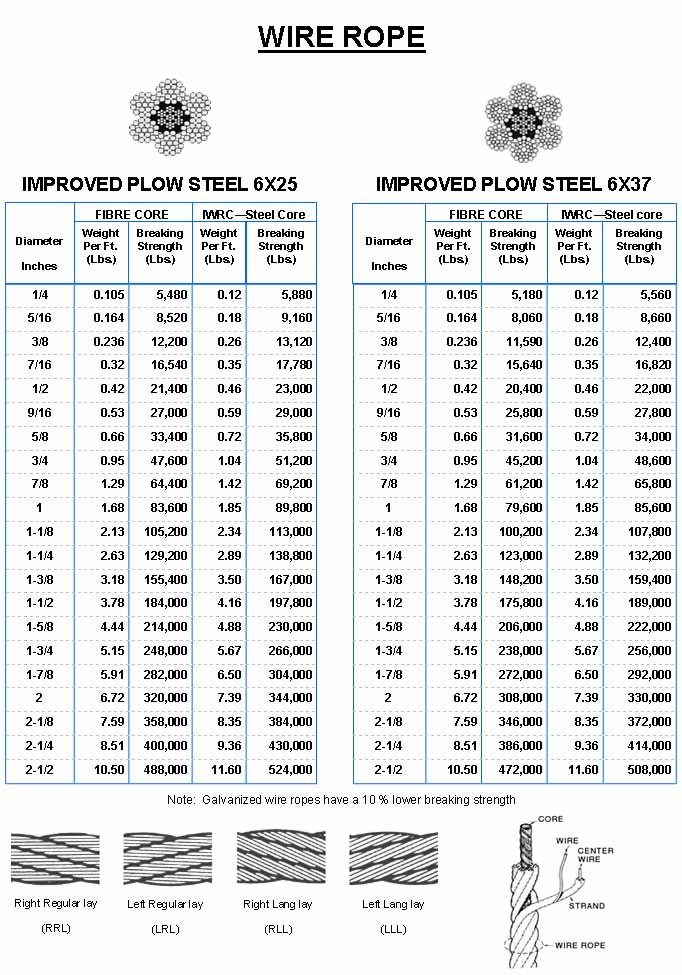

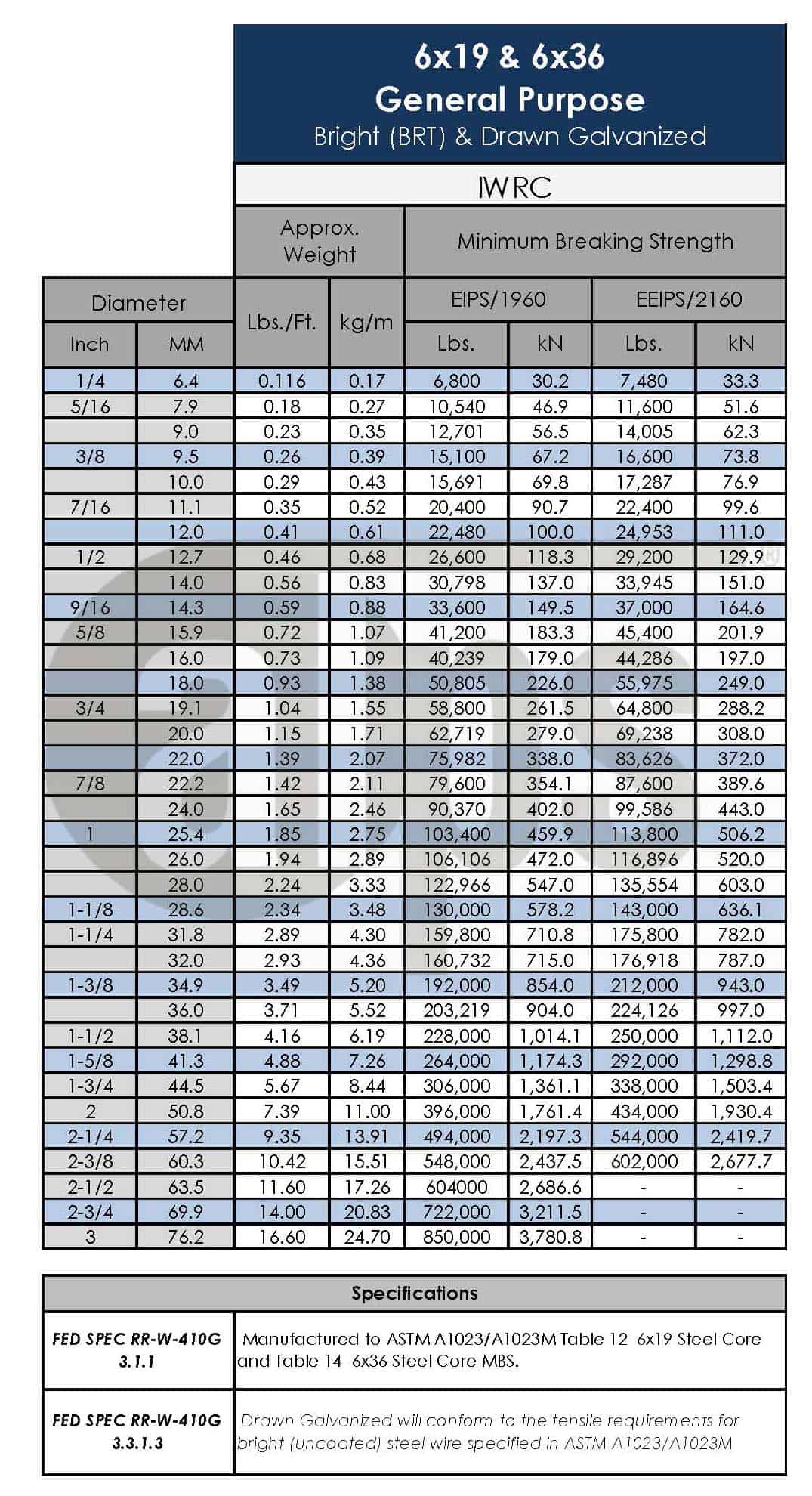

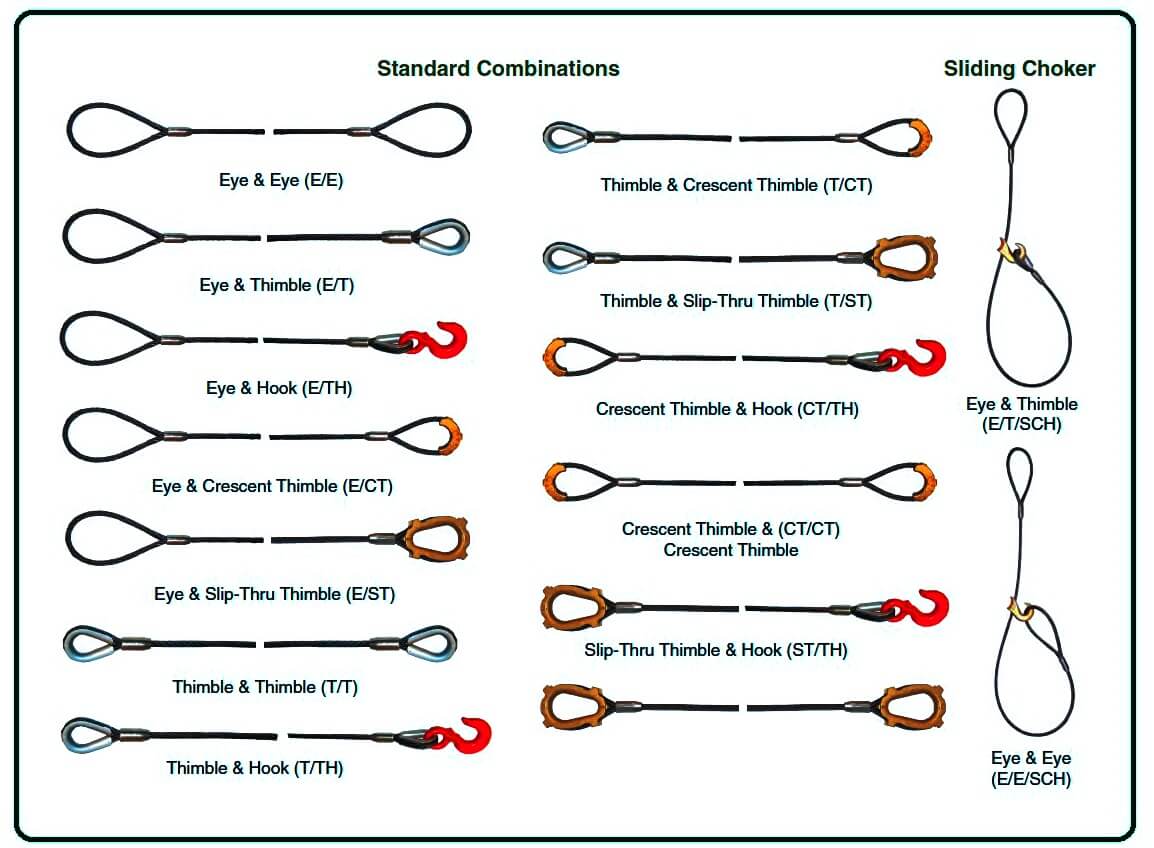

Wire Rope Size Chart - Web wire forming technology is used to form wire ropes and coils from the various wires (such as stainless steel wire) created by the wire drawing process. Bending wire rope reduces its strength. Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: 6 x 19 and 6 x 36 classifications. Download and print wire rope safe load chart. Best for outdoor applications as they are highly resistant to corrosion, especially in or near saltwater environments. Use of iwrc eips rope gives 15% greater capacity than iwrc ip (improved plow) ropes. Proper wire rope sling use and care. Web the following chart lists the size tolerances of wire rope. Web the 6 x 36 classification includes standard six round strand ropes with 27 to 49 wires per strand. Best for outdoor applications as they are highly resistant to corrosion, especially in or near saltwater environments. 316 stainless steel, hot dipped galvanized, and malleable zinc plated. Web we stock all types of wire rope for every application from a truck winch or a pipe choker to a tugboat towing wire or crane rigging. The diameter is measured across the. Whether you're working with 1x7, 1x19, 7x7, or other configurations in 302/304 stainless steel or galvanized steel, our guide provides the essential 'g' factor for each type. Web the following chart lists the size tolerances of standard wire rope. Fully preformed rope wires (3.1) outer wires (3.1.1) filler wires (3.1.3) centre wires (3.1.4) inner wires (3.1.2) core wires (3.1.5) layer. Hooks, chokers, and thimbles are available to fit specific lift requirements. Although the physical characteristics of these two can vary widely, both have the same weight per foot and. Easily see rope size comparisons between inches, mm and rope circumference. The longer it has been in service or the more severe the service, the more thoroughly and frequently it should. Web the 6 x 36 classification includes standard six round strand ropes with 27 to 49 wires per strand. Web how to measure wire rope diameter. Web we stock all types of wire rope for every application from a truck winch or a pipe choker to a tugboat towing wire or crane rigging. Additionally, you will understand the fundamental mechanics. Web the chart below shows minimum tread diameters over which various sizes and constructions of cable should operate. To account for the effect of bend radius on wire rope strength when selecting a sheave, use the table below: Least expensive (per capacity), of all steel slings. > design factors and how to use them. Use of iwrc eips rope gives. However, selecting the proper wire rope for your lifting application requires some careful thought. Hot dipped galvanized (hdg) advantages. Web the following chart lists the size tolerances of standard wire rope. Countless combinations of sling terminations: To account for the effect of bend radius on wire rope strength when selecting a sheave, use the table below: Bending wire rope reduces its strength. Pulley & sheave radius guide. Fully preformed rope wires (3.1) outer wires (3.1.1) filler wires (3.1.3) centre wires (3.1.4) inner wires (3.1.2) core wires (3.1.5) layer of wires (3.1.7) load bearing wires (3.1.6) stitching wire or strand (3.1.8) serving wire or strand (3.1.9) wire tensile strength grade = r (3.1.11) wire tensile. While the. Web the following chart lists the size tolerances of wire rope. Download and print wire rope safe load chart. The diameter is measured across the rope, not from flat to flat. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type. However, selecting the proper wire rope for your lifting application requires some careful thought. Additionally, you will understand the fundamental mechanics behind our most popular rope constructions and classifications. Web the following chart lists the size tolerances of wire rope. Fully preformed rope wires (3.1) outer wires (3.1.1) filler wires (3.1.3) centre wires (3.1.4) inner wires (3.1.2) core wires (3.1.5). M = (10.9 103 n) / (9.81 m/s2) = 1111 kg. 6 x 19 and 6 x 36 classifications. Bending wire rope reduces its strength. Web the following chart lists the size tolerances of wire rope. Web maximum safe mass for a 3/8 wire rope where the safe load is 10.9 kn can be calculated as. Web the following chart lists the size tolerances of standard wire rope. Web dimensions (3.7.) dimension of round wire =. To determine the strength efficiency of 1/2 diameter wire rope using a 10” diameter sheave: Use of iwrc eips rope gives 15% greater capacity than iwrc ip (improved plow) ropes. While the 6 x 19 ropes give primary important for their fatigue resistance. Although the physical characteristics of these two can vary widely, both have the same weight per foot and. Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size. Web the 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Web the chart below shows minimum tread diameters over which various sizes and constructions of cable should operate. Strength wire rope strength in the united states is typically shown in tons of 2,000 lbs. 6 x 19 and 6 x 36 classifications. Web the 6 x 36 classification includes standard six round strand ropes with 27 to 49 wires per strand. Our unique technology and processing machinery facilitate processing with higher precision. Web how to measure wire rope diameter. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. Web there are 3 types of wire rope clips materials:Wire Rope Chart Rope Equipment

Wire Rope Fiber Core Rasmussen Equipment

Wire Rope Size Chart Labb by AG

Wire Rope Lifting Slings AllWays Rigging Gear

WIRE ROPE Delta Cable & Supply

Wire Ropes & Slings Lifting Equipment in Toronto Cable Craft

Wire Rope Chart A Visual Reference of Charts Chart Master

Wire Rope Sizes Chart

WireRopeSlingCapacityCharts.pdf Rope Braid

General Purpose Wire Rope Charleston's Rigging

Our Goal Is To Help You Understand The Components Of A Wire Rope, The Construction Of Wire Rope, And The Different Types Of Wire Rope And What They Might Be Used For.

Download And Print Wire Rope Safe Load Chart.

Fully Preformed Rope Wires (3.1) Outer Wires (3.1.1) Filler Wires (3.1.3) Centre Wires (3.1.4) Inner Wires (3.1.2) Core Wires (3.1.5) Layer Of Wires (3.1.7) Load Bearing Wires (3.1.6) Stitching Wire Or Strand (3.1.8) Serving Wire Or Strand (3.1.9) Wire Tensile Strength Grade = R (3.1.11) Wire Tensile.

Web Wire Forming Technology Is Used To Form Wire Ropes And Coils From The Various Wires (Such As Stainless Steel Wire) Created By The Wire Drawing Process.

Related Post: