X Bar Control Chart

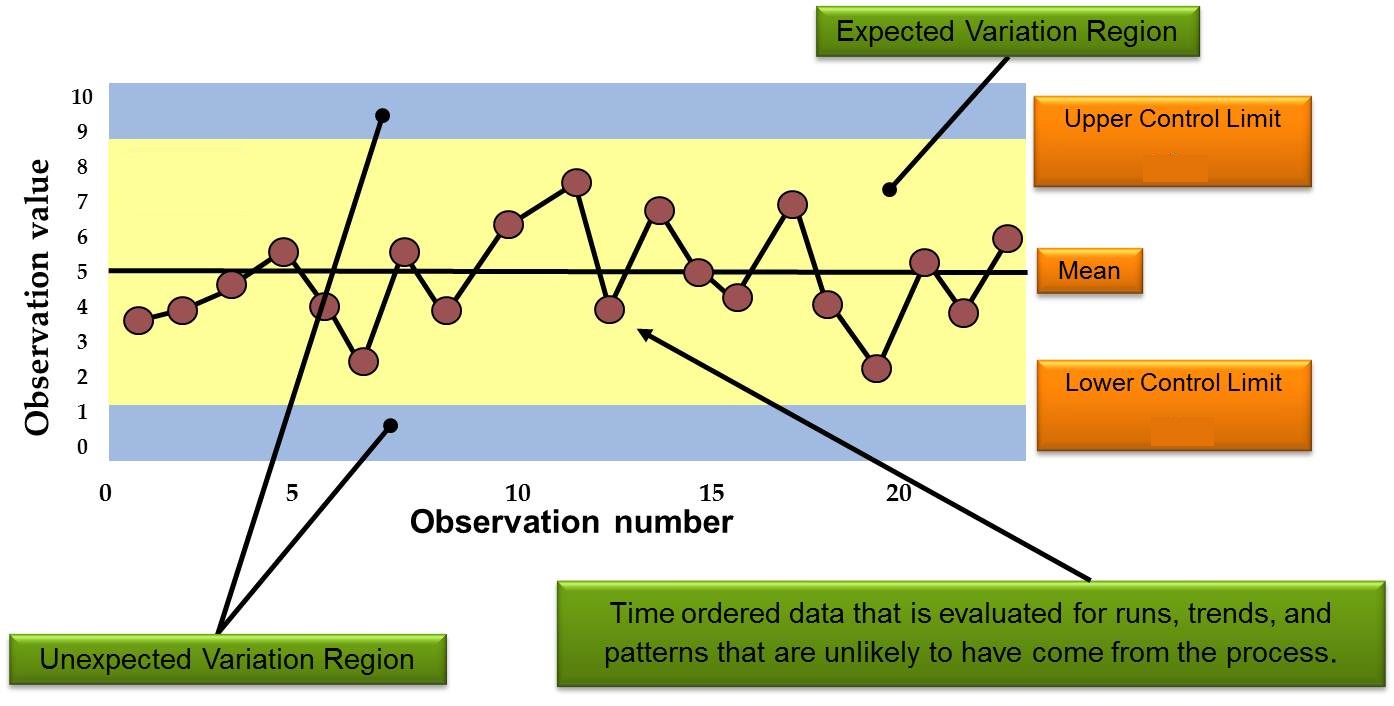

X Bar Control Chart - One chart is for subgroup averages ( x ). Web steps in constructing the xbar chart. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). The charts help us track process statistics over time and help us understand the causes of the variation. Analyze > quality and process > control chart builder. Conversely, the s charts provide a better understanding of the spread of subgroup data than the range. Web the xbar & r chart is the most commonly used control chart. Create xbar r or xbar s control charts to monitor the performance of a continuous variable with subgrouping over time. Useful for identifying special cause changes to the process mean (xbar) Like most other variables control charts, it is actually two charts. The charts help us track process statistics over time and help us understand the causes of the variation. Analyze > quality and process > control chart builder. We begin with x ¯ and s charts. The control limits on both chats are used to monitor the mean. Web x bar & r chart. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. The r chart is used to review the process variation which must be in control to correctly interpret the xbar chart. Quality engineers at a manufacturing plant monitor part lengths. Find the ucl and lcl using the following equations:. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Web what are x bar s control charts? This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web x bar & r chart. One chart. We should use the s chart first to determine if the distribution for the process characteristic is. Walter shewhart, the originator of control charts, proposed a plan for the construction of control charts for the sample mean, and used it as a foundation for the development of the theory of control charts. The charts help us track process statistics over. The charts help us track process statistics over time and help us understand the causes of the variation. X bar s charts often use control charts to examine the process mean and standard deviation over time. Like most other variables control charts, it is actually two charts. Web steps in constructing the xbar chart. This type of control chart is. One chart is for subgroup averages ( x ). Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. X ¯ and s shewhart control charts. Consists of two charts displaying central tendency and variability. X bar s charts often use control charts to examine the process mean and. A(2) can be found in the following table: Useful for identifying special cause changes to the process mean (xbar) X bar s charts often use control charts to examine the process mean and standard deviation over time. Web the xbar & r chart is the most commonly used control chart. Web what are x bar s control charts? Web what are x bar s control charts? They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web steps in constructing the xbar chart. Analyze > quality and process > control chart > xbar control chart. The r chart is used to review the process variation which must be in control. The range (r) chart shows the variation within each variable (called subgroups). Create xbar r or xbar s control charts to monitor the performance of a continuous variable with subgrouping over time. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The x bar & r chart is used for variable. The other chart is for subgroup ranges (r). Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using: Web control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of. We begin with x ¯ and s charts. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Web what are variables control charts? The r chart is used to review the process variation which must be in control to correctly interpret the xbar chart. Analyze > quality and process > control chart > xbar control chart. X ¯ and s shewhart control charts. Find the ucl and lcl using the following equations: Create xbar r or xbar s control charts to monitor the performance of a continuous variable with subgrouping over time. Web the xbar & r chart is the most commonly used control chart. Analyze > quality and process > control chart builder. Conversely, the s charts provide a better understanding of the spread of subgroup data than the range. Like most other variables control charts, it is actually two charts. Useful for identifying special cause changes to the process mean (xbar) Web control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. We should use the s chart first to determine if the distribution for the process characteristic is. The control limits on both chats are used to monitor the mean and variation of the process going forward.

XBar control charts Mission Control

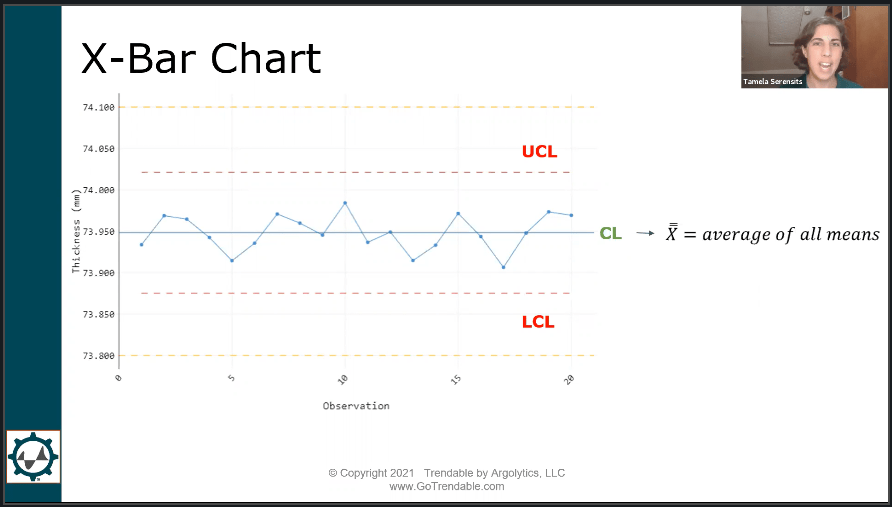

What is an Xbar control chart? TRENDABLE

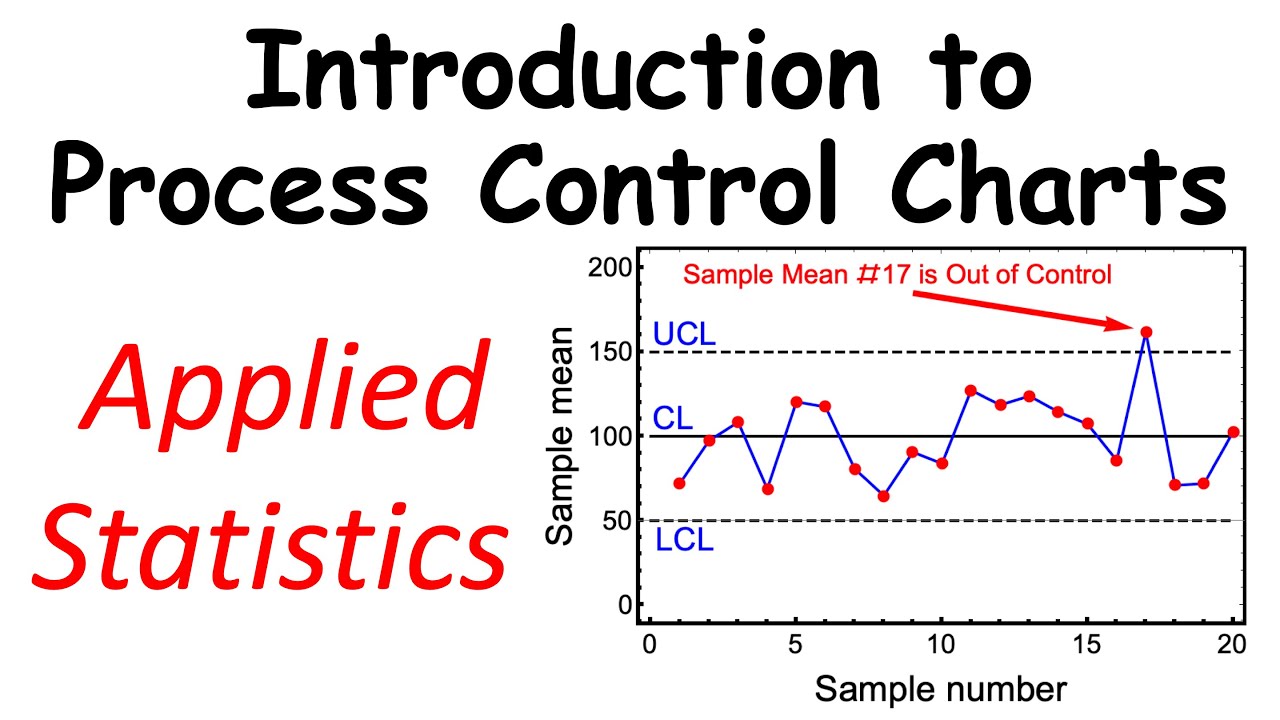

Statistical Process Control Charts for the Mean and Range X Bar Charts

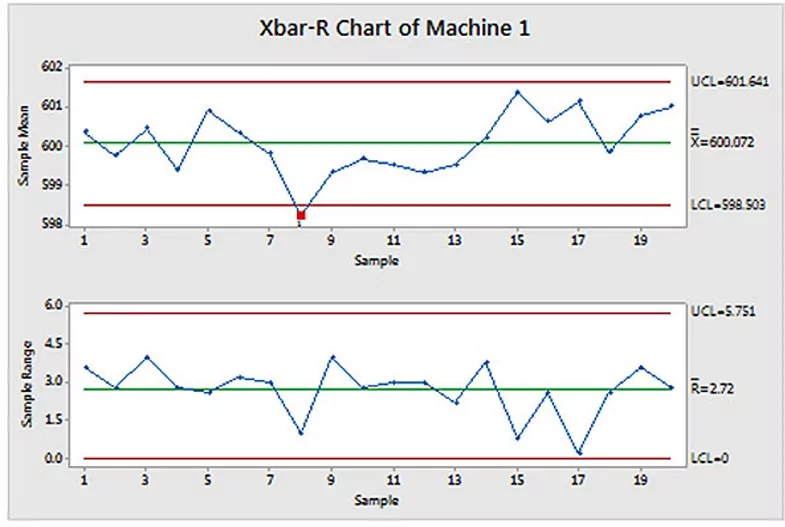

Control Limits for xbar r chart show out of control conditions

X bar control chart

Xbar and R Chart Formula and Constants The Definitive Guide

Xbar Control Chart

After discussing the several aspects and uses ofXbar and R Charts, we

X barS control chart under the traditional method Download

Types of Control Charts Statistical Process Control.PresentationEZE

Process That Is In Statistical Control Is Predictable, And Characterized By Points That Fall Between The Lower And Upper Control Limits.

Web X Bar & R Chart.

X ¯ And S Charts.

The Other Chart Is For Subgroup Ranges (R).

Related Post: