Metal Stud Size Chart

Metal Stud Size Chart - While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data out there. 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel. It’s important to consider the thickness of the frame, the size of the webbing, and the size of the flange. Consider the size of the building before choosing the ideal size. Metal studs are available in different widths, depths, and gauge thicknesses. 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils (12ga). Web metal stud sizes vary in width, thickness, and depth. Web when to use certain metal stud sizes. The gauge of the metal and width of the stud determine the lateral and axial load capacity. They also vary in thickness, from 14 to 26 gauge. The gauge of the metal and width of the stud determine the lateral and axial load capacity. Web when to use certain metal stud sizes. 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils (12ga). Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. Different. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data out there. In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load. 33mil (20ga) and 43mil (18ga) framing products are produced. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated. 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel. The gauge of the metal and width of the stud determine the lateral and axial load capacity. In general, the capacity of a stud depends on many variables — stud. Web metal stud sizes vary in width, thickness, and depth. They also vary in thickness, from 14 to 26 gauge. Consider the size of the building before choosing the ideal size. 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel. Web standard metal stud sizes are 1 ⅝, 2 ½, 3 ⅝, 4, and 6 inches. It’s important to consider the thickness of the frame, the size of the webbing, and the size of the flange. 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data. Consider the size of the building before choosing the ideal size. They also vary in thickness, from 14 to 26 gauge. In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load. Webbing in metal studs is the space in between the studs where plumbing and electrical wires are situated.. The gauge of the metal and width of the stud determine the lateral and axial load capacity. Building a large structure requires thick metal studs with a wide web size. Consider the size of the building before choosing the ideal size. They also vary in thickness, from 14 to 26 gauge. 33mil (20ga) and 43mil (18ga) framing products are produced. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data out there. Web standard metal stud sizes are 1 ⅝, 2 ½, 3 ⅝, 4, and 6 inches. Web metal stud sizes vary in width, thickness, and depth. They also vary in. It’s important to consider the thickness of the frame, the size of the webbing, and the size of the flange. Web standard metal stud sizes are 1 ⅝, 2 ½, 3 ⅝, 4, and 6 inches. 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga) and 97 mils (12ga). While it’s always good to go with an. It’s important to consider the thickness of the frame, the size of the webbing, and the size of the flange. Metal studs are available in different widths, depths, and gauge thicknesses. In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load. 33 mils (20ga), 43 mils (18ga), 54 mils. Metal studs are available in different widths, depths, and gauge thicknesses. The gauge of the metal and width of the stud determine the lateral and axial load capacity. Building a large structure requires thick metal studs with a wide web size. Web when to use certain metal stud sizes. Web metal stud sizes vary in width, thickness, and depth. 33mil (20ga) and 43mil (18ga) framing products are produced with 33ksi steel. Different manufacturers fabricate metal studs of similar sizes, plus some with unique characteristics. Web standard metal stud sizes are 1 ⅝, 2 ½, 3 ⅝, 4, and 6 inches. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel framing based on existing data out there. Web we’ve been asked by a number of clients how to size and build with metal studs a few times. They also vary in thickness, from 14 to 26 gauge. In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load. Consider the size of the building before choosing the ideal size.

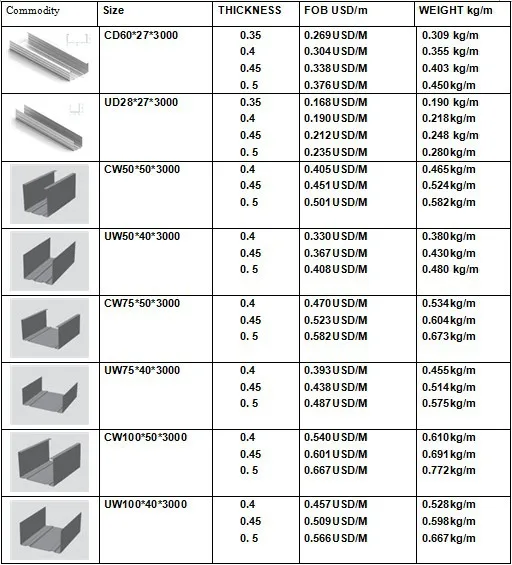

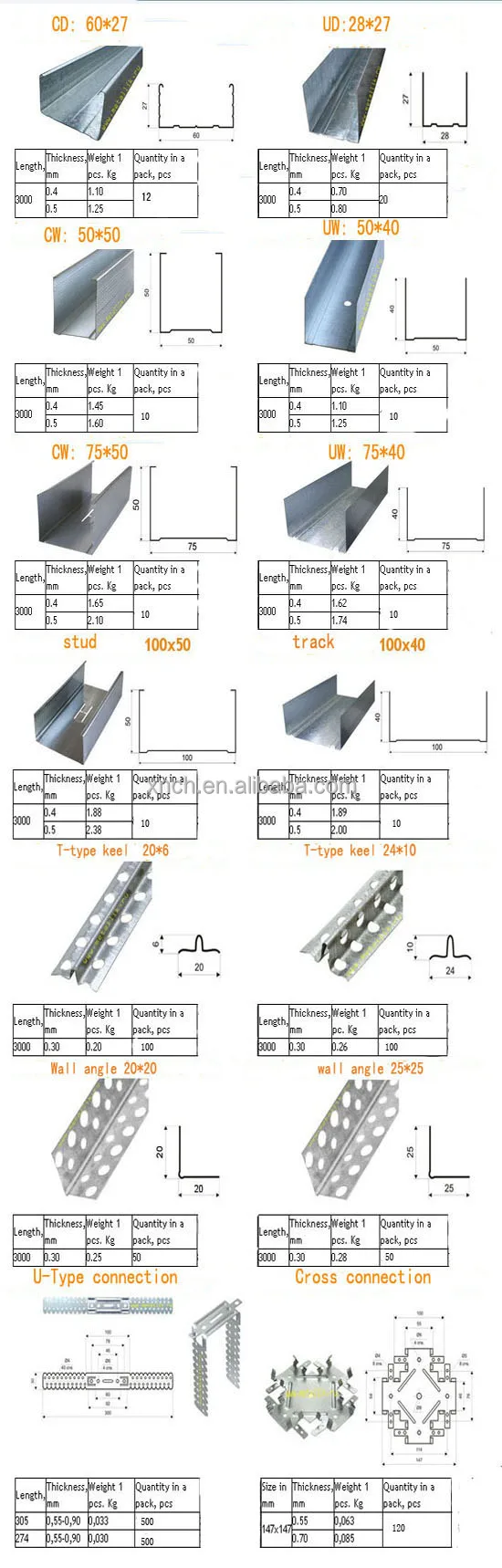

Metal Stud and Track for Drywall System SANLE

Drywall Metal Studs Sizes Buy Stud And Track,Cw And Uw,Drywall

Studs And Tracks Sizes basement wall studs

Wall Stud Size Chart

Sizing framing tables for metal stud framing US Frame Factory

Metal Stud Gauge Chart

Metal Stud Size Chart Ps1200 steel stud track machine jobsite

316 B8 Metric Stainless Steel Studs t A & I Fasteners & Supply

Wall Stud Size Chart

12+ Drywall Metal Studs Sizes, Trend Saat Ini!

Web Metal Stud Size Chart.

It’s Important To Consider The Thickness Of The Frame, The Size Of The Webbing, And The Size Of The Flange.

Webbing In Metal Studs Is The Space In Between The Studs Where Plumbing And Electrical Wires Are Situated.

33 Mils (20Ga), 43 Mils (18Ga), 54 Mils (16Ga), 68 Mils (14Ga) And 97 Mils (12Ga).

Related Post: