Oxy Acetylene Tip Size Chart

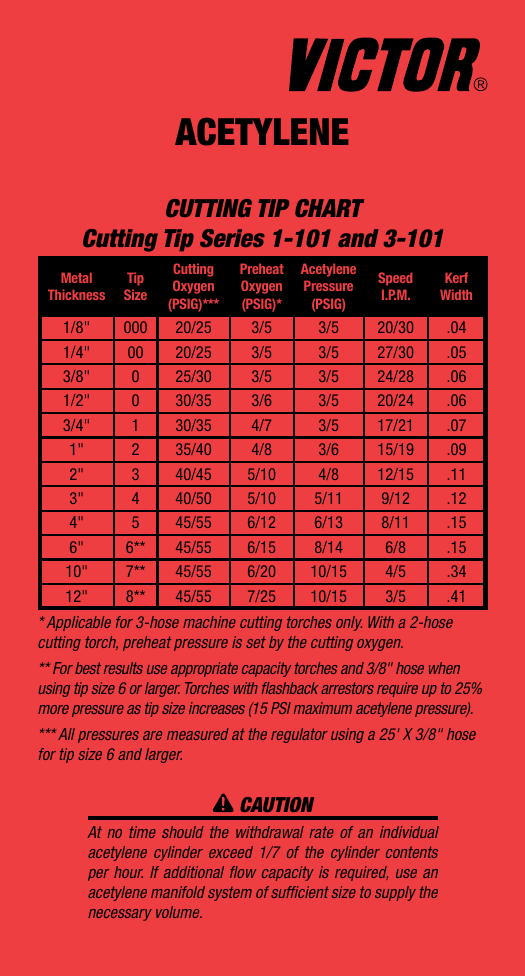

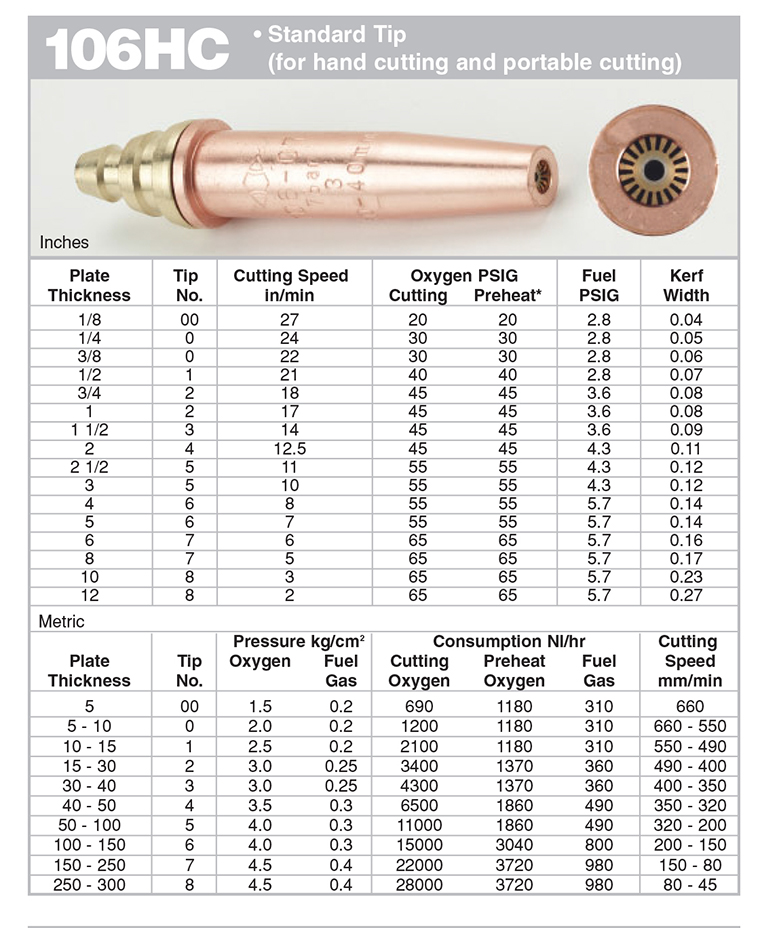

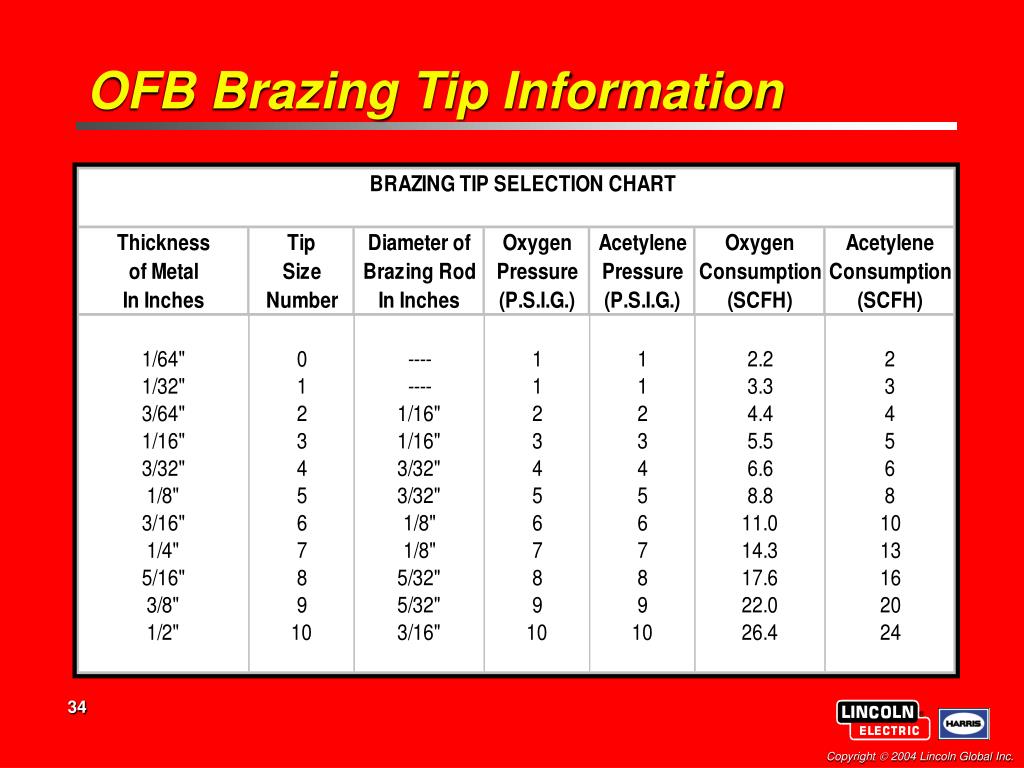

Oxy Acetylene Tip Size Chart - The thickness of the metal being cut is very important because the center hole of the cutting and gouging tip is sized to deliver the proper amount of oxygen at the proper pressure for a specific thickness. There are even different sizing conventions for the united states and canada. The tip size is determined by the orifice for cutting oxygen gas. ** to provide required flow, use 3/8 i.d. In order to be used properly and efficiently. Compare (up to 4 products) style code : Compensate for supply pressure changes. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Web ** to provide required flow, use 10mm i.d. Web the chart indicates the approximate torch oxygen consumption with a neutral flame ratio for various gases: ** for best results use st2600fc series torches and 3/8 hose when using tip size 6 or larger. Web ** to provide required flow, use 10mm i.d. Always use an acetylene cylinder in the up right position so you don't draw any of. The shortest tank, according to the united states size chart, is the mc. There are even different sizing conventions for the united states and canada. In order to be used properly and efficiently. Web medium preheat tip with two milled flat sides. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12. In order of increasing height, they are: Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. Acts as a safety device for the operator & cylinder. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Web shop by brand. Web harris cutting tip charts. Web they range in size from 10 to almost 400 cuft capacity. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Acts as a safety device for the operator & cylinder. A safe flow and mixture of oxygen and gas will make all of the. Precise cnc controlled drilling process ensures consistency in performance and quality. The tip size is determined by the orifice for cutting oxygen gas. Web the chart indicates the approximate torch oxygen consumption with a neutral flame ratio for various gases: Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). There. Pressures are approximate for hose length up to 25 ft.; Each nozzle is individually swaged to insure proper alignment for uniform flame, sizing and. Web the sizing charts of oxy acetylene tanks differ from country to country. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Web harris cutting tip. Compensate for supply pressure changes. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. Commonly used with oxy plate, pipe and profile cutting machines and some hand cutting torches. In order of increasing height, they are: In order to be used properly and efficiently. Hose for size 4 and larger cleaning: In order of increasing height, they are: For additonal information refer to www.harrisproductsgroup.com. Web medium preheat tip with two milled flat sides. The tip is angled at 20º. The tip is angled at 20º. Web the sizing charts of oxy acetylene tanks differ from country to country. The shortest tank, according to the united states size chart, is the mc. Web they range in size from 10 to almost 400 cuft capacity. With a two hose cutting torch, preheat pressure is set by the cutting oxygen. Web harris cutting tip charts. Hose for size 4 and larger cleaning: Pressures are approximate for hose length up to 25 ft.; Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. Always use an acetylene cylinder in the up right position so you don't draw any of the acetone out of the tank. Hose for size 4 and larger cleaning: Acts as a safety device for the operator & cylinder. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Compensate for supply pressure changes. Each nozzle is individually swaged to insure proper alignment for uniform flame, sizing and. Web ** to provide required flow, use 10mm i.d. Use energy “stored” in the supply cylinder. Web they range in size from 10 to almost 400 cuft capacity. The thickness of the metal being cut is very important because the center hole of the cutting and gouging tip is sized to deliver the proper amount of oxygen at the proper pressure for a specific thickness. Data compiled using mild steel as test material. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Commonly used with oxy plate, pipe and profile cutting machines and some hand cutting torches. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. The tip is angled at 20º. ** to provide required flow, use 3/8 i.d. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure).Oxy Acetylene Cutting Tip Size Chart

Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone

acetylene Victor Technologies

Oxy Acetylene Torch Tip Chart

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

Oxy Acetylene Victor Welding Tip Chart

Buy 5pcs/lot H01 2 Oxygen Acetylene welding nozzle

SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

Oxy Fuel Tip Seat Guide American Torch Tip

Oxy Acetylene Tip Chart

A Safe Flow And Mixture Of Oxygen And Gas Will Make All Of The Difference In Your Cutting Torch Safety, Speed, And Effectiveness.

Web Harris Cutting Tip Charts.

There Are Ten Different Oxy Acetylene Tank Sizes Available In The United States.

Hose For Size 4 And Larger.

Related Post: