Refrigerant Piping Size Chart

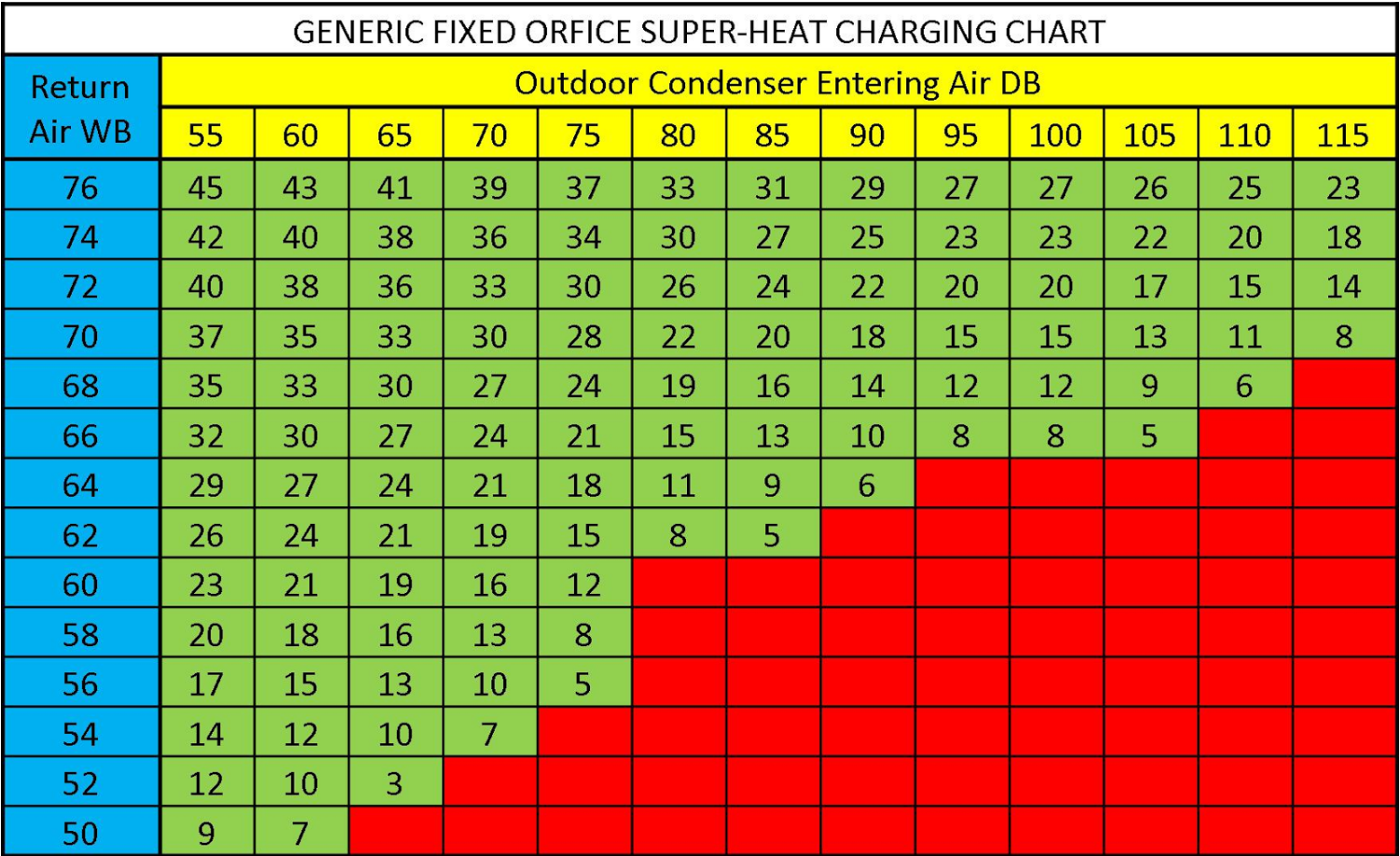

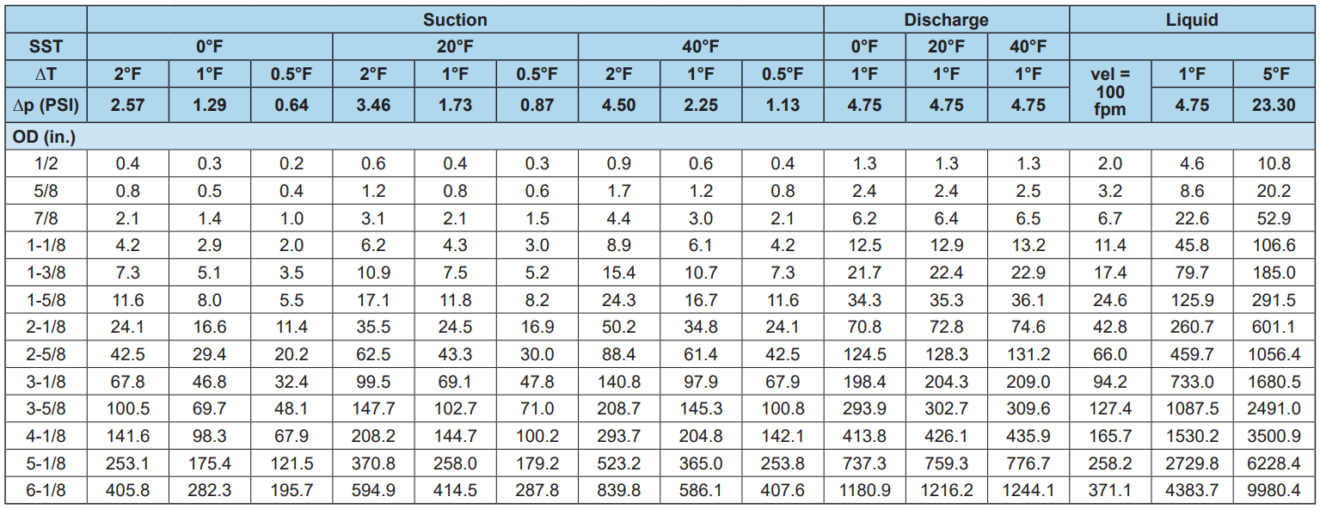

Refrigerant Piping Size Chart - The wrong size piping can cause excessive pressure drops, leading to reduced system efficiency and capacity, while increasing power consumption. Common mistakes to avoid when sizing refrigerant pipes. Overlooking pipe length and elevation. Web the pipe thickness of the refrigerant piping shall comply with the applicable legislation. Web what we need to achieve in pipe sizing • good quality liquid at the tx valve • entrainment of oil back to the compressor • low pressure drop • part load conditions Web good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1 inch per 20 feet. Installation variables may affect the system operation. This manual is dedicated to improving system performance and reliability. Compressor, condenser, evaporator, and throttling device; Refrigerant velocities in vertical lines should be at least 1500 ft/min to ensure good oil return; Line sizes are calculated at rated full load system capacity. Equivalent length is actual length plus friction losses caused by fittings and accessories. Compressor, condenser, evaporator, and throttling device; • provide adequate refrigerant flow to the evaporators, using practical refrigerant line sizes that limit pressure drop • avoid trapping excessive oil so that the compressor has enough oil to operate. Sometimes the role of the piping in the efficiency of a vapour compression system is forgotten or simply, neglected. Web • line sizes are expressed in outside diameter of type “l” copper tubing and calculated at rated full load system capacity. Web the pipe thickness of the refrigerant piping shall comply with the applicable legislation. Compressor, condenser, evaporator, and throttling. Equivalent length is actual length plus friction losses caused by fittings and accessories. The design of refrigerant piping systems involves capacity and efficiency, reliability, oil management, refrigerant charge, sound level, liquid refrigerant control, modulation effectiveness and cost. A properly designed refrigerant piping system ensures oil return, minimizes. Web the piping design of any air conditioning system will affect the performance,. • equivalent length is actual length plus friction losses caused by fittings and accessories. Line sizes are expressed in outside diameter of type “l” copper tubing. Tips for ensuring accurate pipe size selection. • provide adequate refrigerant flow to the evaporators, using practical refrigerant line sizes that limit pressure drop • avoid trapping excessive oil so that the compressor has. The design of refrigerant piping systems involves capacity and efficiency, reliability, oil management, refrigerant charge, sound level, liquid refrigerant control, modulation effectiveness and cost. Sometimes the role of the piping in the efficiency of a vapour compression system is forgotten or simply, neglected. Installation variables may affect the system operation. A properly designed refrigerant piping system ensures oil return, minimizes.. Web piping guide for suva® 410a (eng) suction line size. This manual is dedicated to improving system performance and reliability. Refer to dupont refrigerant expert, version 2.0 for actual velocities and pressure drops. Contact technical services for variations or applications outside those outlined in this document. Web this application guide was created for design engineers and service technicians to demonstrate. • equivalent length is actual length plus friction losses caused by fittings and accessories. Web steps to determine the right pipe size. Line sizes are expressed in outside diameter of type “l” copper tubing. Compressor, condenser, evaporator, and throttling device; Sometimes the role of the piping in the efficiency of a vapour compression system is forgotten or simply, neglected. Installation variables may affect the system operation. Line sizes are calculated at rated full load system capacity. Web the development and design processes of a refrigerating system are commonly focused on the major components of the machine: Operates in either english or s.i. The expansion of piping must be taken into consideration, otherwise a piping failure will result. • line sizes are expressed in outside diameter of type “l” copper tubing. Tube size and component selection. Installation variables may affect the system operation. Capacity losses, and provides for maximum equipment life. Sizes single and vertical risers. Web • line sizes are expressed in outside diameter of type “l” copper tubing and calculated at rated full load system capacity. Line sizes are expressed in outside diameter of type “l” copper tubing. Installation variables may affect the system operation. Web this application guide was created for design engineers and service technicians to demonstrate how to size refrigerant piping.. Tips for ensuring accurate pipe size selection. Only qualified personnel should install and service the equipment. For unique situations please contact honeywell technical support. Sometimes the role of the piping in the efficiency of a vapour compression system is forgotten or simply, neglected. The design of refrigerant piping systems involves capacity and efficiency, reliability, oil management, refrigerant charge, sound level, liquid refrigerant control, modulation effectiveness and cost. The expansion of piping must be taken into consideration, otherwise a piping failure will result. Operates in either english or s.i. This manual is dedicated to improving system performance and reliability. Web refrigerant piping guide • refer to dupont refrigerant expert, version 2.0 for actual velocities and pressure drops. Recap of the importance of correct refrigerant pipe sizing. Web the temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Sizes suction, hot gas discharge and liquid lines. Capacity losses, and provides for maximum equipment life. The diameter of the piping should be chosen based on the required refrigerant flow rate and pressure drop. Web r410a refrigerant piping guide. • all selections are based on a maximum of 65 °f return gas entering the compressor and a refrigerant condensing and liquid line temperature of.

8 R410A Refrigerant Pipe Sizing Charts 2k23

R410a Refrigerant Line Sizing Chart

Refrigerant line sizing Part I general principles and liquid lines

Refrigerant Pipe Sizing Chart For 410a

R410a Refrigerant Line Sizing Chart

Refrigerant Line Charge Adders York Central Tech Talk

Sizing Refrigerant Piping

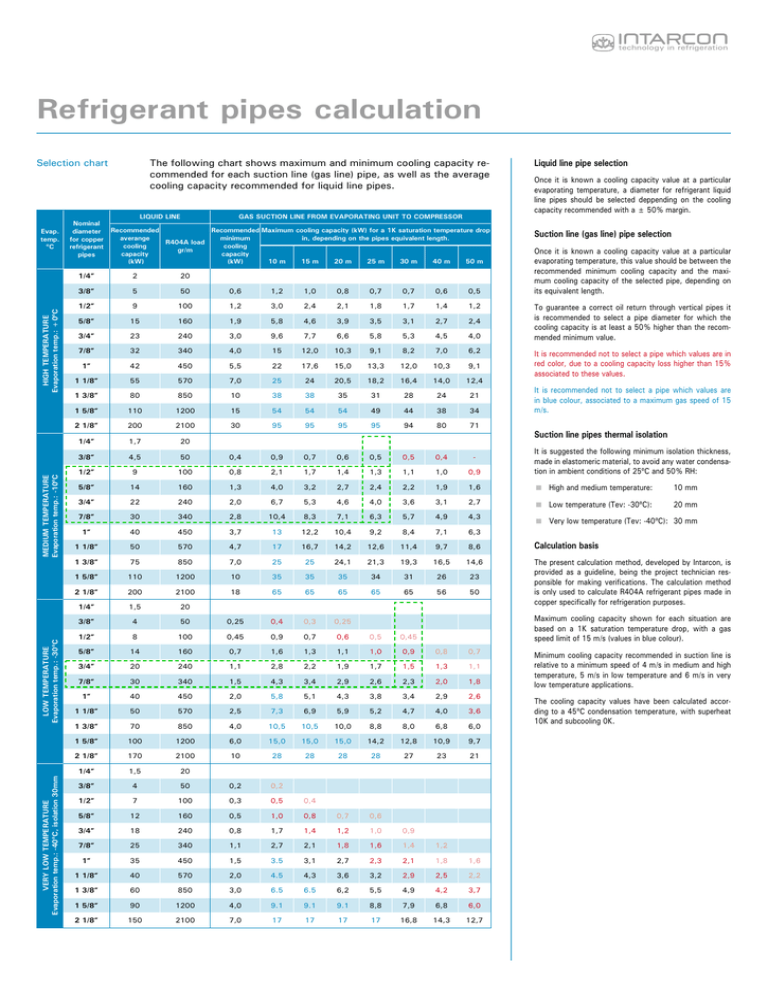

Refrigerant pipes calculation

Refrigerant Piping part2 Refrigeration HVAC/R & Solar

![]()

Refrigerant Pipe Sizing Chart

Installation Variables May Affect The System Operation.

• Provide Adequate Refrigerant Flow To The Evaporators, Using Practical Refrigerant Line Sizes That Limit Pressure Drop • Avoid Trapping Excessive Oil So That The Compressor Has Enough Oil To Operate Properly At All Times • Avoid Liquid Refrigerant Slugging • Be Clean And Dry

• Equivalent Length Is Actual Length Plus Friction Losses Caused By Fittings And Accessories.

The Minimal Pipe Thickness For R410A Piping Must Be In Accordance With The Table Below.

Related Post: