Stainless Filler Rod Chart

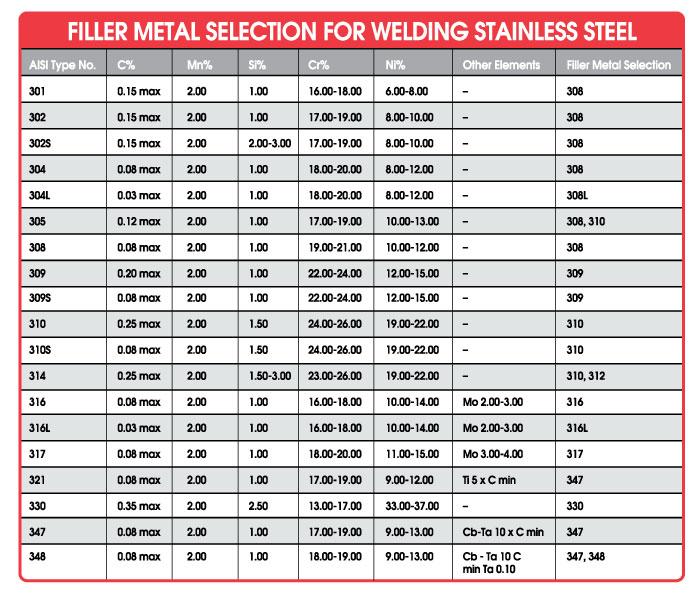

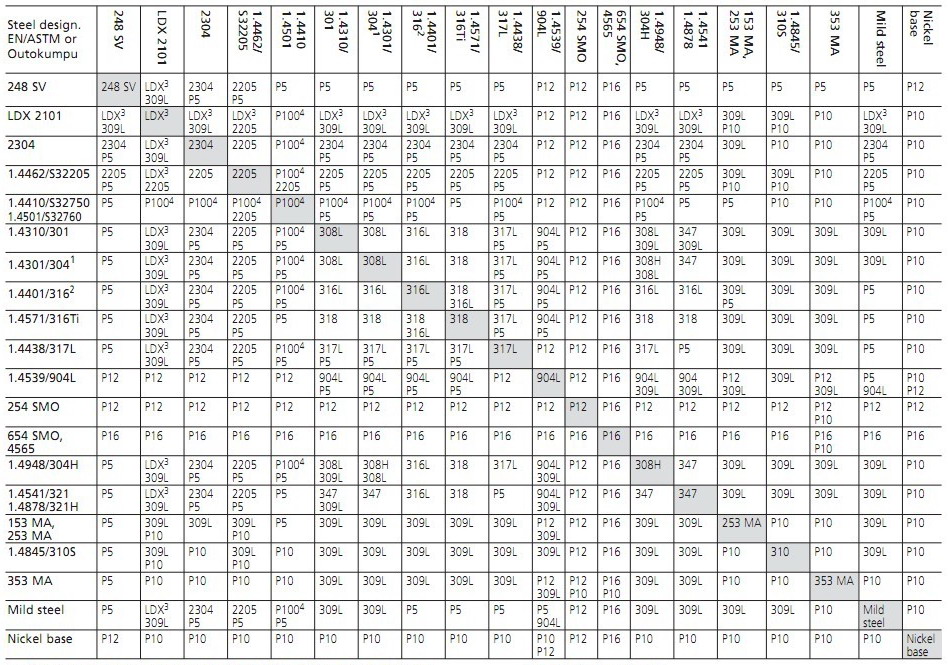

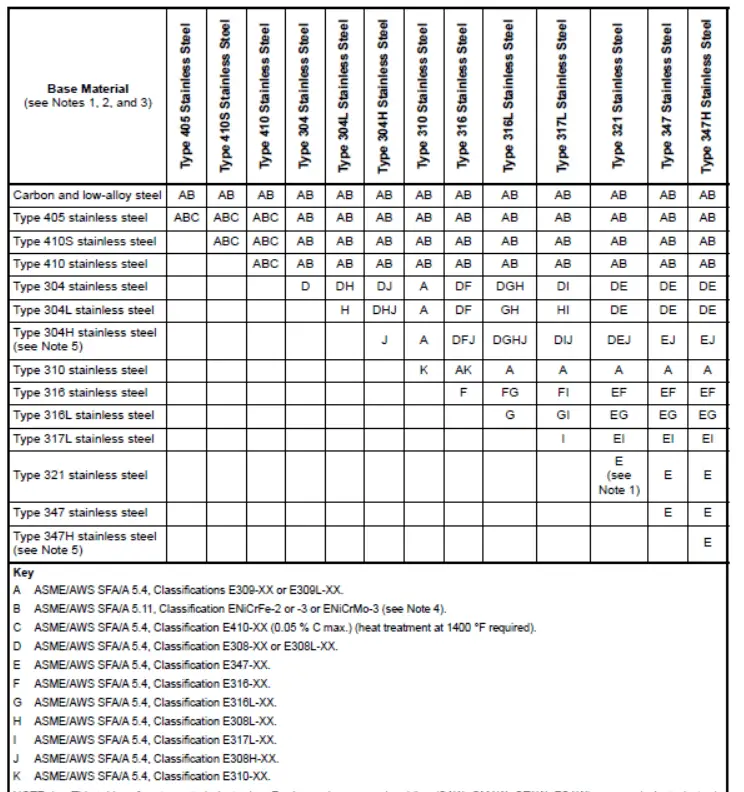

Stainless Filler Rod Chart - Web tig filler rods for super duplex stainless steel. Using this criterion, you can use certain guidelines to zero in on the filler rod alloys and diameters you might want to use. Gupta, secretary american welding society t. Web this chart is only a suggestion of which filler metals should be adequate for the joining of the stainless steels. The proper welding process and filler metal can also help control heat input when welding stainless steel. Tig filler rods for hard facing. Tig filler rods for brazing/bronze welding. In general, the important parameters include the base metal thickness, its composition, and the type of weld joint (butt vs. Midalloy 316lmn will join type 201, 304l, 316l, as well as 3% and 9% nickel alloy steels. Mig wires / tig rods (gmaw/gtaw). Web in this guide, we’ll explore each aspect that goes into proper tig welding filler rod selection from material types and sizes to strength charts so you have everything you need to make an informed decision about what will work best. Anderson esab welding & cutting product j. Smaw or stick electrodes are consumable, meaning they become part of the. Web this chart is only a suggestion of which filler metals should be adequate for the joining of the stainless 420 410 309 410 420 420 420 steels. However, only bare uncoated rods should be used. Light gauge metals less than 1/16 (1.6mm) thick should always be welded with dcsp using argon gas. This handy selection guide to help identify. Web stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347 317 316l 316 314 310 310s 309 309s 304l 303 303 se 201 202 301 302 302b 304 305 308 mild steel. Web chart for selecting stainless steel filler rod. This. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. Aluminium (achf) shield gas flow metal guage. Web this chart is only a suggestion of which filler metals should be adequate for the joining of the stainless 420 410 309 410 420 420 420 steels. Tig filler rods for aluminium. Web home > resources >. Tig filler rods for mild steel. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Web chart for selecting stainless steel filler rod. Deloach jr, 2nd vice chair naval surface warfare center r. Smaw or stick electrodes are consumable, meaning they become part of the weld and are also referred to as a filler electrode or welding. Aluminium (achf) shield gas flow metal guage. Web available in gtaw, gmaw, er316lmn midalloy 316lmn (din 1.4455) is an austenitic stainless steel wire primarily used in the cryogenic industry to obtain impact toughness and high strength. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. This handy selection guide to help identify the best. Note that these tables do not attempt to include all possible choices. Further, there are a number of proprietary base materials and castings for which the filler metals used do not have an aws classification available at this time. Deloach jr, 2nd vice chair naval surface warfare center r. Aluminium (achf) shield gas flow metal guage. 22% eureka 26 (aws. Note that these tables do not attempt to include all possible choices. Mig wires / tig rods (gmaw/gtaw) stick electrodes (smaw) subarc (saw) copper; Actual application should dictate the proper alloy choice. Web this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire and strip) for gas metal arc welding, submerged arc welding, and other. Instances the chart should be used as a reference only. 1.6mm or no filler rod: Web available in gtaw, gmaw, er316lmn midalloy 316lmn (din 1.4455) is an austenitic stainless steel wire primarily used in the cryogenic industry to obtain impact toughness and high strength. Download pdf version of this chart view chart for stick welding electrodes. Web home > resources. Trailing gas is not required for stainless steel welding such as aisi 304. Mig wires / tig rods (gmaw/gtaw) stick electrodes (smaw) subarc (saw) copper; Midalloy 316lmn will join type 201, 304l, 316l, as well as 3% and 9% nickel alloy steels. Actual application should dictate the proper alloy choice. This handy selection guide to help identify the best weldclass. Web also, manufacturers usually have detailed charts to help select a filler rod. Trailing gas is not required for stainless steel welding such as aisi 304. Web chart for selecting stainless steel filler rod. Using this criterion, you can use certain guidelines to zero in on the filler rod alloys and diameters you might want to use. This does not mean that other filler metal alloys are not recommended or of less quality. Gupta, secretary american welding society t. Web stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347 317 316l 316 314 310 310s 309 309s 304l 303 303 se 201 202 301 302 302b 304 305 308 mild steel. 22% eureka 26 (aws e6013) applications: Tig filler rods for magnesium. Aluminium (achf) shield gas flow metal guage. What do you know about the metallurgy of stainless steel? Mig wires / tig rods (gmaw/gtaw). By matching them as shown in grey color, you can find the suitable tig welding rod for any stainless steel material grade. Instances the chart should be used as a reference only. Light gauge metals less than 1/16 (1.6mm) thick should always be welded with dcsp using argon gas. Web this chart is only a suggestion of which filler metals should be adequate for the joining of the stainless steels.

How To Stick Weld Stainless Steel

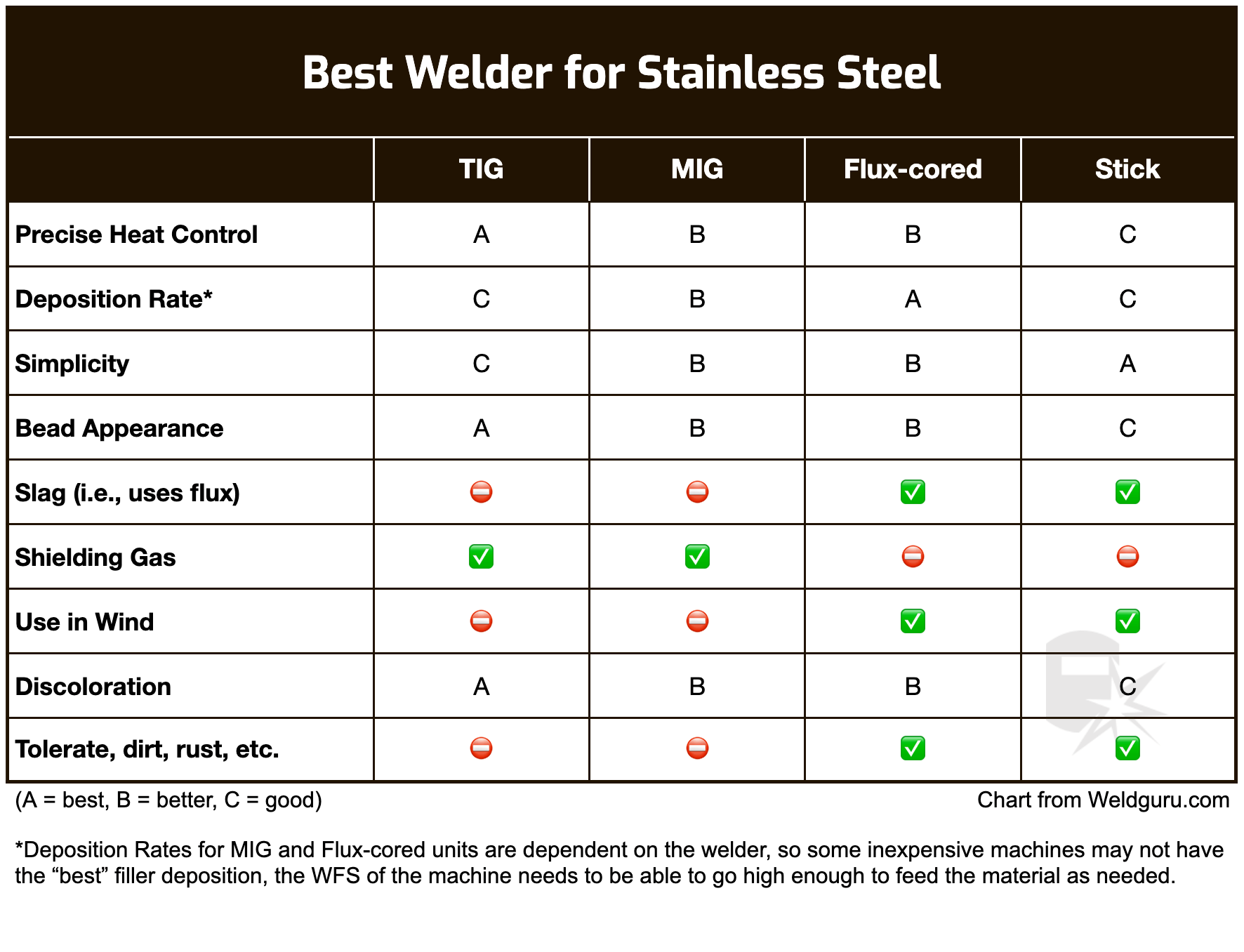

How to Weld Stainless Steel A Complete Guide (2022)

Stainless Steel Filler Rod Chart

Welding austenitic stainless steel The Fabricator

Tig Filler Rod Chart Stainless

Tig Filler Rod Sizes

Filler Metals For Welding Stainless Steel LDX2101 S32205 2304 254SMO

Stainless Steel Filler Rod Chart

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Welding Electrode and Filler wire Selection Charts

Web This Chart Is Only A Suggestion Of Which Filler Metals Should Be Adequate For The Joining Of The Stainless 420 410 309 410 420 420 420 Steels.

View Technical Guides For Guidance On Welding Various Metals And Selecting The Right Hobart Brothers.

Web Available In Gtaw, Gmaw, Er316Lmn Midalloy 316Lmn (Din 1.4455) Is An Austenitic Stainless Steel Wire Primarily Used In The Cryogenic Industry To Obtain Impact Toughness And High Strength.

Note That These Tables Do Not Attempt To Include All Possible Choices.

Related Post: